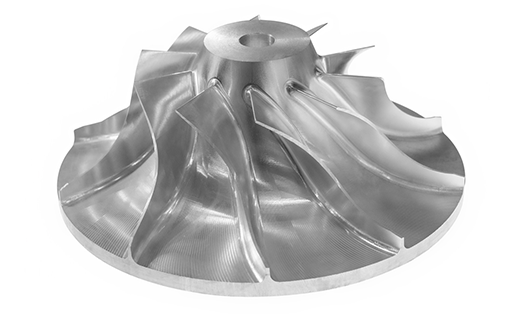

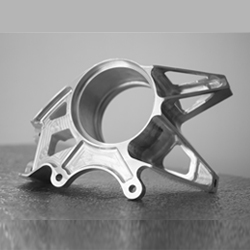

About CNC Machining

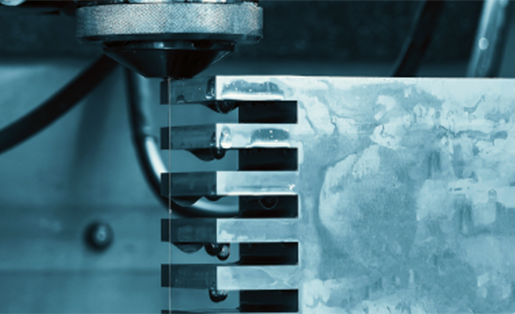

CNC Machining Services

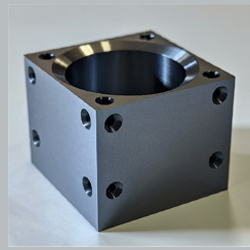

CNC Milling Services

Online Quote

Precision multi-axis milling (3-axis, 4-axis and 5-axis) for complex parts.

Our vetted network delivers rapid prototyping and high-volume production with tolerances to ±0.020 mm and capabilities for sub- ±0.010 mm precision on demand.

DFM feedback during quoting to optimize design and guaranteed quality per ISO 9001:2015, AS9100D standards

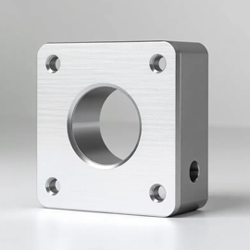

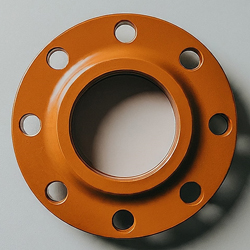

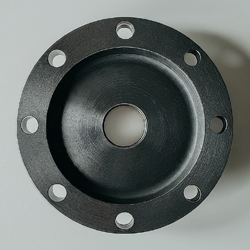

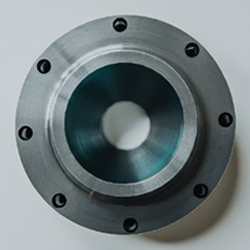

CNC Turning Services

Online Quote

High-accuracy lathe machining for rotational parts, with Capablity of diameters up to 500 mm and lengths to 4,500 mm

in steel, titanium, brass, and engineered plastics with material traceability, RoHS compliance, and heat treatment protocols. Threading/tapping for all standard sizes (M1–M100) and custom threads.

Lead times from 3 days, supporting prototypes to 100,000+ part production runs.

CNC EDM Services

Online Quote

Precision wire and sinker EDM for complex parts in hardened steel, carbide, titanium, Inconel, and tool steels. Can achieve ±0.004 mm tolerances and mirror-smooth finishes without mechanical

stress – ideal for contours, mold cavities, sharp corners, and blind keyways. Capable of workpieces

up to 1,200 × 685 × 355 mm, with surface finishes from as-cut (125 Ra) to electropolishing, passivation, or self-lubricating PTFE impregnation.

Micro-EDM hole drilling | Fine wire EDM for medical devices | AS9100 sinker EDM

CNC Machining Tolerances

Achieve functional fit and cost efficiency by aligning designs with standard and achievable tolerances for milling, turning, and EDM processes. This reference details critical dimensional limits across hole positions, surface flatness, and geometric profiles to balance precision with manufacturability.

| Process | Feature | General Tolerance | Tight / Achievable Tolerance |

|---|---|---|---|

| Milling | Linear Dimensions | ±0.125 mm (±0.005") | ±0.025 mm (±0.001") |

| Hole Position (Ø<25mm) | ±0.100 mm | ±0.012 mm | |

| Bore Diameter (H7) | ±0.050 mm | ±0.007 mm | |

| Flatness (100×100mm) | 0.100 mm | 0.015 mm | |

| Surface Finish (Ra) | 3.2 μm (125 μin) | 0.4 μm (16 μin) | |

| Turning | Diameter (Ø<50mm) | ±0.075 mm | ±0.015 mm |

| Length | ±0.100 mm | ±0.020 mm | |

| Concentricity | 0.050 mm | 0.010 mm | |

| Thread Pitch (M6-M24) | ±0.15 mm | ±0.10 mm | |

| Surface Finish (Ra) | 1.6 μm (63 μin) | 0.2 μm (8 μin) | |

| Wire EDM | Linear Dimensions | ±0.020 mm | ±0.004 mm |

| Corner Radius | R0.15 mm | R0.05 mm | |

| Surface Finish (Ra) | 1.6 μm (63 μin) | 0.8 μm (32 μin) | |

| Sinker EDM | Cavity Depth | ±0.030 mm | ±0.010 mm |

| Blind Keyway Width | ±0.025 mm | ±0.008 mm | |

| Surface Finish (Ra) | 3.2 μm (125 μin) | 0.8 μm (32 μin) |

CNC Machining Materials

|

Aluminum Aluminum CNC MachiningAluminum is one of the most popular materials for CNC machining due to its excellent machinability, strength-to-weight ratio, and corrosion resistance. It allows for high-speed machining, reducing production time and costs while maintaining precision. Aluminum is ideal for prototyping and manufacturing across industries like aerospace, automotive, and electronics, as it can be easily anodized or finished for enhanced durability and aesthetics. Its versatility and wide range of alloys, such as 6061 and 7075, make it suitable for everything from structural components to complex geometry parts. About Aluminum Available Aluminum Alloys

|

|

Copper Copper CNC MachiningCopper offers exceptional electrical and thermal conductivity, making it a good choice for CNC machining components in the electrical, electronics, and heating industries. Its excellent machinability allows for the manufacturing of complex, high-precision parts with fine details. While softer than some metals, copper is easily machined into prototypes and end-use components like busbars, heat exchangers, and connectors. Its natural corrosion resistance and ability to be plated ensure durable, long-lasting performance in demanding applications. About Copper Available Cpeer Alloys Available Copper Finishes |

|

Brass Brass CNC MachiningBrass is a highly machinable material prized in CNC machining for its smooth finish, low friction, and excellent corrosion resistance. Its inherent manufacturability allows for high-speed machining with minimal tool wear, making it a cost-effective choice for both prototyping and high-volume production runs. Brass parts are commonly manufactured for applications in plumbing, electrical, musical instruments, and decorative hardware, often requiring no additional finishing due to its naturally appealing gold-like appearance. About Brass Available Brass Alloys Available Brass Finishes |

|

Bronze Bronze CNC MachiningBronze is a highly versatile material for CNC machining, valued for its exceptional durability, corrosion resistance, and excellent machinability. It is ideal for manufacturing high-performance components like bearings, bushings, and gears, particularly in demanding industries such as marine, aerospace, and automotive . Bronze alloys, including C932 (bearing bronze) and C954 (aluminum bronze), offer superior wear resistance and low friction, ensuring longevity and reliability in prototypes and end-use parts . Its thermal conductivity aids in heat dissipation during machining, reducing the risk of deformation and maintaining dimensional accuracy . With options for various surface finishes, bronze is a cost-effective choice for both prototyping and large-scale production runs. About Bronze Available Bronze Alloys Available Bronze Finishes |

|

Tool Steel Tool Steel CNC MachiningTool Steel is a high-carbon alloy steel engineered for exceptional hardness, wear resistance, and dimensional stability, making it ideal for CNC machining of industrial tools, dies, molds, and high-stress components . Its superior manufacturability allows for precision machining of complex parts, though it is often processed in an annealed state to enhance machinability before heat treatment for optimal performance . Common grades like A2 (air-hardening), D2 (high chromium), and H13 (hot-work) offer tailored properties such as toughness, thermal resistance, and minimal distortion during hardening, catering to prototyping and large-scale manufacturing across aerospace, automotive, and tooling industries . With applications ranging from cutting tools and injection molds to wear-resistant fixtures, Tool Steel ensures longevity and reliability in demanding environments, supported by options for finishing to achieve tight tolerances and enhanced surface durability. About Tool Steel Available Tool Steel Alloys Available Tool Steel Finishes |

|

Stainless Steel Stainless Steel CNC MachiningStainless Steel is a versatile and robust material for CNC machining, offering exceptional corrosion resistance, high strength, and excellent durability for demanding applications across medical, aerospace, automotive, and food processing industries. While its work-hardening properties require specific machining strategies, grades like 304 (general purpose) and 316 (marine-grade) provide superior manufacturability for complex prototypes and end-use parts. Stainless steel components can be precision-machined to tight tolerances and finished with processes like passivation or electropolishing to enhance their inherent resistance to corrosion and wear, ensuring reliability in harsh environments and critical assemblies. About Stainless Steel Available Stainless Steel Alloys Available Stainless Steel Finishes |

|

Alloy Steel Alloy Steel CNC MachiningAlloy Steel is a high-strength material ideal for CNC machining, offering superior toughness, wear resistance, and responsiveness to heat treatment for demanding manufacturing applications. With excellent machinability in grades like 4140 and 4340, it enables the production of durable prototypes and end-use parts such as gears, shafts, and structural components in industries like automotive, aerospace, and heavy machinery. Its versatility allows for precise machining to tight tolerances, and it can be further enhanced through treatments like carburizing or quenching to achieve desired mechanical properties, making it a reliable choice for both prototyping and high-volume production runs. About Alloy Steel Available Alloy Steel Alloys Available Alloy Steel Finishes |

|

Mild Steel Mild Steel CNC MachiningMild Steel is a cost-effective and versatile material for CNC machining, prized for its excellent weldability, formability, and overall machinability. Its low carbon content makes it easier to machine compared to higher-carbon steels, enabling efficient prototyping and high-volume manufacturing of durable parts like brackets, frames, and structural components. While it lacks the corrosion resistance of stainless steel, mild steel can be treated with finishes such as plating, painting, or powder coating to enhance its durability and appearance for applications in automotive, construction, and general industrial use. About Mild Steel Available Mild Steel Alloys Available Mild Steel Finishes |

|

Titanium Titanium CNC MachiningTitanium is a premium material for CNC machining, renowned for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, making it ideal for high-performance applications in aerospace, medical, and automotive industries. While its low thermal conductivity and tendency to work-harden pose machining challenges, these can be mitigated with specialized tooling, precise parameters, and advanced cooling techniques. Grades like Ti6Al4V (Grade 5) offer versatility for prototyping and end-use manufacturing, though material costs require careful economic planning. With options for anodizing and other finishes, titanium parts achieve enhanced durability and precision, ensuring reliability in critical environments. About Titanium Available Titanium AlloysAvailable Titanium Finishes |

|

ABS ABS CNC MachiningABS is a versatile thermoplastic prized in CNC machining for its excellent impact resistance, machinability, and durability, making it ideal for functional prototyping and end-use parts. Its low-cost manufacturability allows for rapid production of components in industries like automotive, consumer goods, and electronics, where strength and lightweight properties are critical. ABS can be easily machined to tight tolerances and is compatible with post-processing treatments such as sanding, painting, or plating to achieve a high-quality surface finish or specific aesthetic requirements. About ABS Available ABS Finishes |

|

Acrylic Acrylic CNC MachiningAcrylic is a versatile and cost-effective material for CNC machining, prized for its exceptional optical clarity, lightweight properties, and ease of manufacturability. It machines cleanly to achieve precise, smooth edges and tight tolerances, making it ideal for prototyping and manufacturing components like lenses, displays, signs, and aesthetic housings. With excellent compatibility with finishing techniques such as polishing, painting, or laser etching, acrylic parts can achieve a high-gloss, professional appearance suited for consumer electronics, automotive lighting, and retail displays. About Acrylic Available Acrylic Finishes |

|

Delrin Delrin CNC MachiningDelrin (acetal) is an engineering thermoplastic renowned for its exceptional strength, stiffness, and low friction, making it a top choice for CNC machining precision components like gears, bearings, and bushings . Its excellent machinability allows for high-speed production with tight tolerances, ideal for both prototyping and manufacturing across automotive, aerospace, and medical industries . With superior wear resistance, creep resistance, and dimensional stability, Delrin performs reliably in demanding environments, though it requires careful tool selection and cooling strategies to mitigate heat sensitivity during machining . Available in grades like Delrin 150, PTFE-filled, and glass-filled variants, it offers tailored properties for specific applications, from self-lubricating parts to high-stress components. About Delrin Available Delrin Alloys Available Delrin Finishes |

|

HDPE HDPE CNC MachiningHDPE (High-Density Polyethylene) is a versatile thermoplastic ideal for CNC machining, offering excellent chemical resistance, high impact strength, and low moisture absorption, making it suitable for prototyping and manufacturing durable components in industries like packaging, marine, and construction . Its superior machinability allows for efficient production of complex parts with tight tolerances, though careful cooling and tool selection are recommended to manage thermal expansion . With FDA-compliant grades and recyclability, HDPE is a cost-effective choice for both functional prototypes and end-use parts, such as containers, pipes, and structural components, often requiring minimal post-processing . About HDPE Available HDPE Finishes |

|

Nylon Nylon CNC MachiningNylon is an engineering thermoplastic ideal for CNC machining, offering excellent wear resistance, high strength, and good chemical stability, making it suitable for both prototyping and manufacturing durable components like gears, bushings, and structural parts. Its machinability allows for precision production with tight tolerances, though proper cooling and tooling strategies are recommended to manage its hygroscopic nature and prevent deformation. With grades such as Nylon 6, Nylon 66, and glass-filled variants, it provides tailored properties for applications in automotive, aerospace, and industrial equipment, and can be finished or treated to enhance performance and aesthetics. About Nylon Available Nylon Alloys Available Nylon Finishes |

|

Polycarbonate Polycarbonate CNC MachiningPolycarbonate is an engineering thermoplastic renowned for its exceptional impact resistance, optical clarity, and high machinability, making it ideal for CNC machining prototypes and end-use parts. Its manufacturability allows for precision production of complex components like lenses, protective shields, and structural housings in industries such as aerospace, automotive, and medical devices. While its low thermal conductivity requires optimized tooling and cooling strategies to prevent melting, polycarbonate can be easily finished with polishing, coating, or anti-scratch treatments to enhance durability and aesthetics for demanding applications. About Polycarbonate Available Ploycarbonate Finishes |

|

As Machined StandardOur as-machined finish delivers parts directly from CNC machining with a standard surface roughness of Ra 3.2 μm, maintaining tight dimensional tolerances without post-processing. This cost-effective option eliminates additional steps, reducing lead time and ideal for functional prototypes, internal components, and applications where aesthetics are secondary. Visible tool marks are typical, but roughness can be refined to Ra 1.6 μm or lower for improved smoothness while preserving material integrity. Compatible with metals and plastics, it ensures precision and durability for industrial, automotive, and aerospace components. Learn more Finish Specifications

|

|

As Machined MediumOur as-machined medium finish offers a superior surface quality with a typical surface roughness of Ra 1.6 μm, reducing visible tool marks for a smoother appearance and enhanced functionality. This CNC finish provides an excellent balance between cost-effectiveness and improved aesthetics, ideal for parts requiring a cleaner look without the added time or expense of secondary polishing. It ensures tight tolerances are maintained and is suitable for a wide range of CNC machining materials, including metals and plastics, making it a versatile choice for functional prototypes, jigs, fixtures, and end-use components in industries like automation, robotics, and consumer electronics. Learn more Finish Specifications

|

|

As Machined FineAchieve exceptional part quality with our as-machined fine finish, delivering a superior surface roughness of Ra 0.8 μm for a smooth, clean appearance with minimal visible tool marks. This high-precision CNC finish eliminates the need for secondary processing, maintaining tight tolerances and reducing lead time for projects requiring both excellent functionality and refined aesthetics. Ideal for visible components, consumer products, and high-performance applications in industries like medical, aerospace, and electronics, it ensures reliable results with a professional look directly from the machine. Learn more Finish Specifications

|

|

Bead BlastingAchieve a uniform, satin-smooth matte texture with our bead blasting finish, a popular surface finishing process that uses fine glass beads to clean, deburr, and refine part surfaces without impacting dimensional accuracy. This non-abrasive treatment is ideal for removing light tool marks, providing a consistent aesthetic appearance, and improving corrosion resistance by creating a low-reflective surface perfect for priming, painting, or powder coating. Compatible with a wide range of metals including aluminum, stainless steel, and titanium, it is widely used for consumer products, enclosures, and components across the medical, automotive, and aerospace industries. Learn more Finish Specifications

|

|

BrushedElevate your product's aesthetic with our brushed metal finish, a mechanical surface treatment that creates a consistent linear grain pattern for a excellent, satin-smooth appearance. This decorative finish enhances visual appeal while effectively masking minor scratches and wear, making it ideal for visible consumer-facing components like appliance housings, architectural trim, and electronic panels. The process improves corrosion resistance and is compatible with stainless steel, aluminum, and brass, offering both durability and a sophisticated matte look without additional coatings. Learn more Finish Specifications

|

|

Chromate Conversion CoatingEnhance corrosion resistance and adhesion for aluminum parts with our chromate conversion coating (chem film) process. This chemical film finish creates a protective, conductive layer that shields components from rust and oxidation while providing an excellent base for paint or powder coating. Available in clear (Alodine) or distinctive yellow (yellow iridite) finishes, it is a compliant treatment widely used in aerospace, military, and electronic industries for its durability and electrical conductivity. Learn more Finish Specifications

|

|

PolishingDeliver a flawless, high-gloss mirror finish with our professional metal polishing services, designed to achieve an exceptional aesthetic appeal and a smooth, non-porous surface. This multi-stage abrasive process progressively refines the part to a reflective, mirror-like shine with an ultra-low surface roughness (Ra 0.1 μm or lower), ideal for decorative components, and consumer products. Highly effective on stainless steel, aluminum, and brass, this finish enhances corrosion resistance and is a staple in the medical, food processing, and luxury goods industries. Learn more Finish Specifications

|

|

Powder CoatingAchieve a exceptionally durable and high-quality protective finish with our powder coating services. This dry finishing process electrostatically applies free-flowing powder to a part before heat curing it into a uniform, resilient layer that is highly resistant to chipping, scratching, fading, and corrosion. Available in an extensive color matching palette including textures, metallics, and gloss levels, it provides superior aesthetic appeal and functional protection for both indoor and outdoor applications. This environmentally friendly, is ideal for automotive components, consumer products, architectural pieces, and industrial equipment. Learn more Finish Specifications

|

|

Black OxideDeliver a durable, corrosion-resistant matte black finish with our black oxide coating process. This conversion coating creates a thin, non-reflective surface that enhances wear resistance and minimizes light glare, ideal for tools, fasteners, and mechanical components. The process adds minimal thickness, preserving tight tolerances and dimensional accuracy, and is compatible with steel, stainless steel, and copper alloys. Commonly used in automotive, military, and industrial applications, it provides an affordable, functional finish with improved aesthetics and added protection against rust. Learn more Finish Specifications

|

|

Electroless PlatingAchieve a uniform, high-performance protective coating with our electroless plating services, a chemical process that deposits a nickel-phosphorus alloy without electricity for consistent coverage even on complex geometries and internal surfaces. This autocatalytic method ensures exceptional corrosion resistance, wear resistance, and hardness (up to HV 1000 with heat treatment) while maintaining tight tolerances (±0.0001 inches) and dimensional accuracy. Ideal for aerospace, automotive, medical, and electronics components, it provides a smooth, semi-bright finish with thicknesses from 3μm to 40μm, enhancing durability and functionality for parts like valves, surgical instruments, and connectors. Compatible with steel, aluminum, and copper alloys, this RoHS-compliant finish also offers improved EMI shielding and lubricity. Learn more Finish Specifications

|

|

Anodizing Type 2Enhance durability and corrosion resistance with our Type II sulfuric acid anodizing process, which creates a hard, protective oxide layer on aluminum parts. This finish provides excellent wear resistance and electrical insulation while allowing for a range of color dye options, from clear and black to vibrant custom hues. Ideal for aerospace, military, and consumer goods, it meets specifications and improves both part longevity and aesthetic appeal. Learn more Finish Specifications

|

|

Anodizing Type 3 (Hard)Maximize component durability with our hard coat anodizing (Type III) process, which builds a thick, dense oxide layer for extreme wear resistance, thermal insulation, and corrosion protection. Achieving a surface hardness exceeding 60 Rockwell C, this finish is ideal for high-stress applications in aerospace, military, and industrial equipment. Available in dark gray to black shades, it meets specifications and provides superior performance for gears, pistons, and valves operating in harsh environments. Learn more Finish Specifications

|

CNC Machining Design Guidelines

To prevent costly redesigns and manufacturing delays, consider these critical thresholds for milling, turning, and EDM processes. This table outlines essential parameters for wall thickness, feature sizes, and geometric constraints to ensure first-pass success.

| Feature | CNC Milling | CNC Turning | EDM (Wire/Sinker) |

|---|---|---|---|

| Wall Thickness | 1.0 mm (metals) 1.5 mm (plastics) |

0.8 mm (metals) 1.2 mm (plastics) |

0.3 mm (hardened steel) 0.5 mm (carbide) |

| Hole Depth | ≤6× diameter Min. Ø: 0.5 mm |

≤5× diameter Min. Ø: 0.3 mm |

Through-cuts only (Wire) ≤20× Ø (Sinker) |

| Internal Corners | R0.5 mm+ Min: R0.2 mm |

R0.3 mm+ Min: R0.1 mm |

R0.05 mm (Wire) R0.1 mm (Sinker) |

| Tolerances (Standard) | ±0.125 mm | ±0.075 mm | ±0.020 mm (Wire) ±0.030 mm (Sinker) |

| Tolerances (Tight) | ±0.020 mm (35% extra cost) | ±0.015 mm (35% extra cost) | ±0.004 mm (Wire) ±0.010 mm (Sinker) |

| Text Engraving | 0.8 mm deep × 5 mm font | 0.5 mm deep × 3 mm font | Not recommended |

| Threads | M2+ (cut) M1.6+ (formed) |

M1+ (external) M1.2+ (internal) |

Not applicable |

| Undercuts | Avoid (unless 5-axis) Min. width: 3 mm |

Avoid (unless live tooling) | Standard in cavities Min. width: 0.1 mm |

| Surface Finish (Ra) | 3.2 μm (as-machined) 0.4 μm (polished) |

1.6 μm (as-turned) 0.2 μm (polished) |

0.8 μm (Wire) 1.6 μm (Sinker) |

| Critical Tips | Add draft (1-2°) for deep pockets Avoid cross holes <Ø1 mm |

Chamfer edges (0.2×45°) Max L/D ratio: 10:1 |

Wire EDM: Avoid tapers <1° Sinker: Add 0.3 mm electrode clearance |

Get a Project Review | Contact Our Engineering Team | Request a Callback

Clarwe's Quality & Certifications Guarantee

All parts are validated in-house: Clarwe's Guarantee of Zero-Defect Parts

Every component is sourced from our vetted ISO/AS-certified manufacturing partners, then 100% physically inspected at our facility before shipment. Unlike others, we enforce a 3-stage custody protocol:

| Material Compliance: | We order and validate material certifications (RoHS, REACH, mill test reports) on your behalf. |

| In-House Verification: |

Dimensional accuracy checks via CMM, VMM, 2D height gauges and precision tools. Critical feature validation against your drawings (hole positions, thread fits, flatness). Visual inspection for surface defects, burrs, and cosmetic flaws. |

| Final Certification: | Full documentation including material certs, CoCs, and inspection logs. |

| We guarantee: | ±0.020 mm tolerances on all

shipped parts (validated in-house). Zero paperwork gaps – we manage all supplier certifications. 100% physical custody – no direct supplier shipments delivering zero-defect compliance from prototype to 100,000+ part production runs. |

Why Choose Clarwe for Online CNC Machining Services?

We deliver end-to-end CNC solutions through our rigorously vetted global network of manufacturing partners and certified suppliers, ensuring your prototypes or production runs— rapid, small-batch, or high-volume - meet the highest standards.

Advantages:

1. Expertise: Upload your CAD file for real-time pricing, lead times, and design-for-manufacturability (DFM) feedback.

2. Quality Assured:

Our ISO 9001:2015, ISO 13485, and AS9100D-certified suppliers guarantees compliance.

Options include inspections, material certifications, and CoCs.

3. Flexible Production:

a. Materials: 50+ metals and plastics.

b. Services: Rapid prototyping to large-scale production.

c. Shipping: Global logistics with tariffs specified(if any) - No hidden charges!

4. Seamless Workflow: Technical drawings accepted. Dedicated support ensures on-time delivery of precision parts.

Clarwe's Platform Advantage

Our integrated dashboard delivers end-to-end project command—streamlining workflows while ensuring transparency at every stage. Experience seamless coordination from initial request to final delivery, all within a single secure interface.

Submit & Configure

| RFQ Initiation |

Upload CAD files (STEP, IGES, SLDPRT) and drawings Specify requirements: materials, tolerances, finishes, inspection protocols Request custom documentation: material certs, CMM reports, customs forms |

| Real-Time Quoting |

Receive online DFM analysis with cost drivers flagged Adjust configurations (e.g., material substitutions) to optimize pricing |

Order Execution & Oversight

| Document Management |

Submit customs declarations, commercial invoices, and HS codes Upload purchase orders or approve terms for payment Access digital invoices with tax/line-item breakdowns |

| Production Intelligence |

Track progress and updates View Shop floor photos/videos Access Inspection reports, quality documents and Material certifications Monitor shipping status with carrier integrations |

Proactive Collaboration & Support

| Engineer Engagement |

Send technical queries and status enquiries to our engineers via encrypted chat Receive resolution timelines for technical queries |

| Quality Assurance Hub |

Access pre-shipment documentation: First-article inspection reports, dimensional reports and quality

documents Approve/reject deliverables via annotated media |

| Post-Delivery Excellence |

Initiate reorders with one-click cloning Log support tickets for non-conformances Archive project history (drawings, certs, comms) for audits |

Industries specialized

Aerospace

Automotive

Consumer Products

Medical

Frequently Asked Questions about CNC Machining

We enforce rigorous, vertically integrated quality control:

Manufacturing: 100% of production occurs in ISO 9001:2015/AS9100D-certified facilities

Vetted Partner Audits: Suppliers pass monthly performance reviews and annual on-site audits for critical metrics like on-time delivery (>99.2%) and defect rates (<0.5%).

Never. Unlike platforms that add 15-30% broker fees, we offer all-inclusive pricing:

Online Quotes: Includes tariffs specified(if any), mill certs and shipping.

Change Orders: Design modifications pre-production are free. Post-production adjustments incur costs only with written approval.

Volume Discounts: Save up to 30% on 500+ units.

Yes – we specialize in high-complexity work:

Multi-Axis Machining: 5-axis milling for contours/undercuts; 11-axis mill-turn for large aerospace components.

Tolerance Expertise: ±0.025mm standard. Achieve ±0.005mm with CMM validation.

Large Parts: Machine components up to 2,000 × 1,000 × 500mm.

Industry-leading speed without premium pricing:

Prototypes: 1–3 days (machined metals/plastics).

High-Volume: 10,000+ parts in 14 days.

Real-time tracking and daily production updates prevent delays.

Metals: Titanium, stainless 316L, aluminum 7075-T6.

Plastics: FDA-compliant PEEK, Ultem 1010, Radel® PPSU.

Finishes: Anodizing (Type II/III), passivation, Ni-Teflon plating, MEDCOAT™ for implants.

Full material certifications (RoHS, REACH, FDA) provided with every order.

Your security is non-negotiable:

NDA/IP Agreements: Enforced at supplier and employee levels. Designs are purged post-production.

Certifications: ISO 9001:2015, ISO 13485:2016 (medical), AS9100D.

Save 15-30% without sacrificing quality:

Small-Batch Optimization: Nest multiple parts in one setup to reduce costs by 40% .

Price Match: We beat any validated quote from competitors .

Our quality assurance is fundamentally different. Unlike marketplace models that rely on supplier self-reporting, we perform 100% in-house, physical inspections at our facility. Every part is validated using CMMs, optical comparators, and precision hand tools against your drawing. We include free inspection reports and material certifications with every order, while competitors often charge extra for these critical documents. This hands-on approach ensures ±0.025 mm tolerances and prevents the post-delivery surprises common with broker platforms.

We machine over 50+ metals and engineering-grade plastics, from common aluminum 6061 and 303 stainless to exotic alloys like Titanium Gr5, and PEEK. Crucially, we provide full material traceability (mill test reports) for every project at no additional cost. This includes compliance with RoHS, REACH, and ASTM standards, which is essential for aerospace, medical, and automotive applications.

Our standard machining tolerance is ±0.025 mm, which meets the needs of most applications. We can consistently hold ±0.025 mm for critical features and, depending on the part geometry and material, can achieve ±0.020 mm for milling and ±0.015 mm for turning. All tight tolerances are validated with in-house CMM inspection to ensure compliance.

Yes, and it's a core part of our service. Within hours of uploading your CAD file, our engineers—not an automated algorithm—provide actionable DFM analysis. We flag potential issues like thin walls, sharp internal corners, difficult-to-machine features, and tolerance conflicts, along with specific suggestions to reduce cost and improve manufacturability, all at no charge.

We accept all major CAD formats, including STEP, IGES, SLDPRT. For full drawing specification, you can also upload PDFs with GD&T. Our system automatically analyzes your 3D model and provides online pricing, lead time, and preliminary DFM feedback.

Absolutely. We specialize in seamless scaling:

Prototyping: 1-10 parts.

Low-Volume/Batch Production: 10 - 10,000 parts.

High-Volume Production: 10,000+ parts.

Our connected network of partners allows us to optimize the manufacturing process for any volume, ensuring

consistency from your first prototype to full-scale production.

You have full visibility through our online customer portal.

From this dashboard, you can:

• Review and approve quotes.

• Message your dedicated project engineer.

• View real-time production updates and photos.

• Access and download inspection reports and material certs pre-shipment.

• Track shipping and delivery.

This level of transparency eliminates the "black box" experience of other platforms.