About Offline CMM Programming

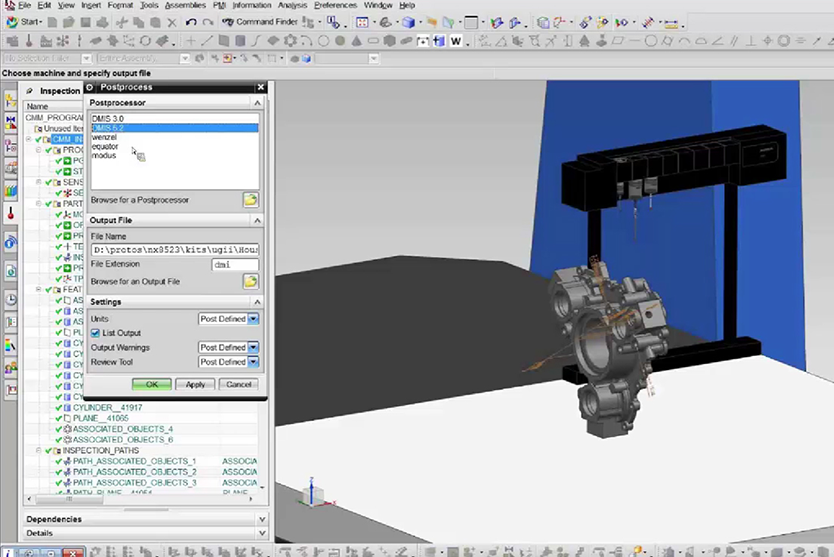

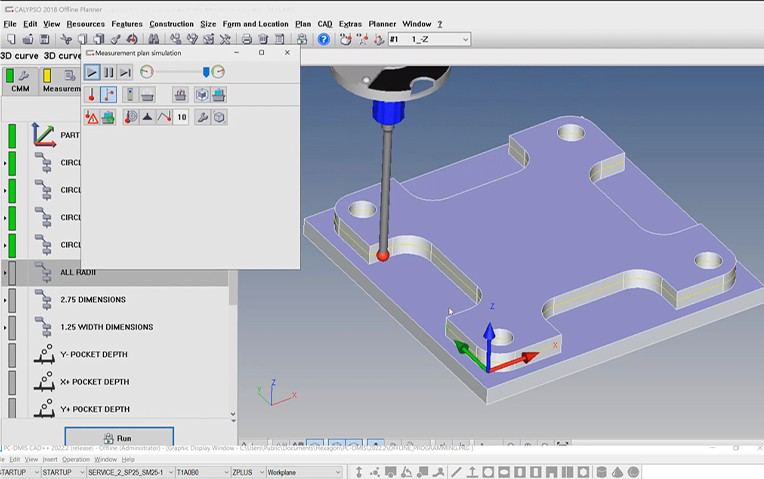

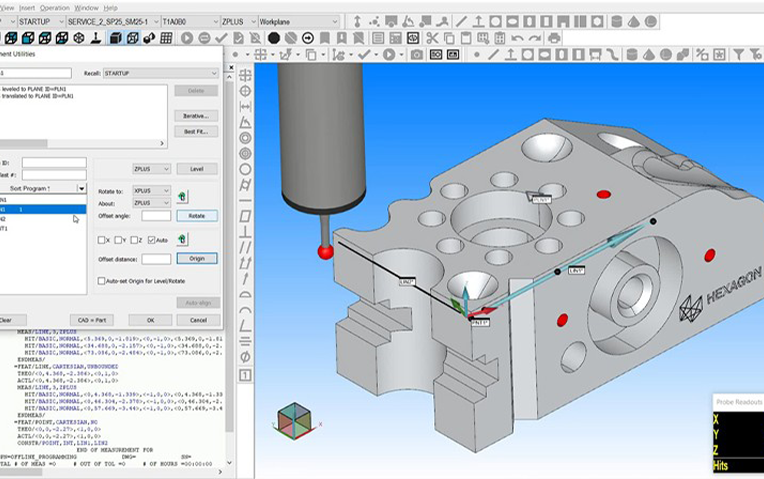

Offline CMM Programming is an advanced metrology methodology where inspection routines are developed entirely within a virtual simulation environment, completely decoupled from the physical Coordinate Measuring Machine (CMM). Instead of occupying the production CMM for hours to manually teach probe paths, metrologists use a "digital twin" of the exact CMM, its probe head and styli within specialized software like PC-DMIS or CALYPSO. The process begins by importing the native 3D CAD model of the part, from which all geometric features, dimensions and GD&T callouts are extracted to build a comprehensive and collision-free measurement plan.

This approach eliminates costly machine downtime, allowing the CMM to remain in production while new programs are created. The virtual program undergoes rigorous simulation and validation, including probe path optimization and measurement uncertainty analysis, to guarantee first-run accuracy. The final output is a ready-to-run program that can be seamlessly deployed to the physical CMM, drastically reducing first-article inspection (FAI) time, minimizing human error and ensuring repeatable, high-precision measurement results for every production run.

Why Outsource Offline CMM Programming?

| Problem | Solution |

|---|---|

|

Traditional on-machine CMM programming forces your production-critical inspection equipment offline for hours or even days. This creates a cascade of costly impacts: Production Delays: 8-24 hours of lost inspection capacity per new part program Rushed Errors: Manual programming under pressure risks ±50 µ measurement deviations Overtime Burns: QA teams working nights/weekends to compensate for backlog Missed Milestones: First-article inspections (FAI) delayed by 5-8 days on average |

Clarwe's Offline CMM Programming decouples programming from production. We transform your CAD models into precision inspection routines without touching your CMM: Zero Machine Occupation Program development in virtual environments (PC-DMIS/CALYPSO simulators) Collision-Free Guarantee: Probe paths validated against your CMM's digital twin Speed-to-Inspection: Routines delivered in 24-48 hours with setup sheets & run videos Cost Reclamation: Redirect 90% of programming hours back to production inspection |

How It Works

Precision Offline CMM Programming in 4 Simple Steps

Upload your 3D CAD model (STEP/IGES/ParaSolid) and provide:

- Critical GD&T callouts & tolerances

- CMM machine model + probe configuration

- Supported Formats: CATIA V5, SOLIDWORKS, NX, Creo, Inventor, JT

Our AS9100-certified metrologists:

- Recreate your CMM's digital twin in PC-DMIS/CALYPSO

- Design optimized probe paths with collision avoidance

- Expertise: Level 3-certified in PC-DMIS 2023.2/CALYPSO 2022

Rigorous virtual testing ensures:

- Measurement accuracy: ±(4.5 + L/75) µm

- Full GD&T compliance: ASME Y14.5 standard

- Deliverable: Video simulation of inspection run

Receive within 24-48 hours:

- Machine-ready program file: (.PRG/.DMIS)

- Setup sheet: Probe alignment instructions

- Virtual run video + SPC report templates

Our CMM Programming Services

Offline Programming

Online QuotePC-DMIS Programming & Calypso Programming

Using our offline CMM programming and simulation software, we can create inspection programs based on your CAD model or drawing before your part is manufactured. Once your physical component is ready, the CMM measurement program will be all set to go, allowing you to reduce lead times and enhance your productivity.

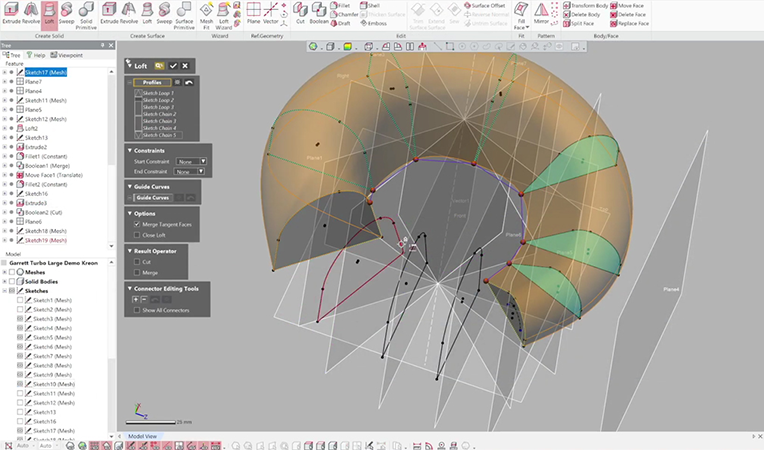

Reverse Engineering

Online Quote Quick turn-around Reverse-Engineered Parts!If you need to recreate a part without technical drawings, our reverse engineering services can help. Using advanced laser scanners and CAD tools, our reverse engineering services enable us to reproduce replacement parts in a timely and cost-effective manner. All we need is a sample part and we can produce an accurate CAD model and drawings for the part.

Technical Capabilities

Capability Matrix

| Domain | Systems Supported | Technical Specifications |

|---|---|---|

| Software | PC-DMIS 2023.2, CALYPSO 2022, PolyWorks 2024 |

- 5-axis simultaneous path planning - Automated GD&T validation per ASME Y14.5-2018 |

| CMM Hardware | Zeiss CONTURA/PRISMO, Hexagon Global S, Mitutoyo CRYSTA-Apex, Nikon HN-C |

- Volumetric accuracy: 1.9 µm + L/250 - Max part size: 4 m x 2 m x 1.5 m - Multi-sensor configurations |

| Probe Systems | VAST XTR gold, TP200, Renishaw PH20, K-Series (vision) |

- Scanning speed: 500 pts/sec - Repeatability: 0.12 µm @ 20°C - Tip diameters: 0.3 mm - 8 mm |

Specialized Technical Expertise

• Blade profile analysis

• Jig/fixture alignment for wing assemblies

• Orthopedic implant surface mapping

• Surgical robot component verification

• Cell stacking parallelism

• Coolant channel leak path analysis

• Busbar flatness/coplanarity reports

Deliverables Suite

• Machine-ready program files (.PRG, .DMIS, .CMM)

• AS9102 / PPAP documentation packages

• 3D deviation heatmaps (PolyWorks / PCDMIS)

• Dimensional summary reports (Excel / PDF)

• Measurement uncertainty statements (ISO 17025)

• Collision test videos (MP4)

Advantages

Quantifiable Advantages of Offline CMM Programming

| Benefit | Metric |

|---|---|

| Zero Machine Downtime | 100% CMM utilization during programming |

| 45% Lower Inspection Costs | Top CMM Programmers from $20/hour |

| Sub-10 µ Measurement Certainty | ±(4.5 + L/75) µm accuracy guarantee |

| 70% Faster First-Article Inspection | Programs in 24-72 hrs vs. 5-8 days |

| Risk-Free Engineering Changes | 3-hr emergency revision turnaround |

Why Choose Clarwe?

Engineering‑Led Precision, Unmatched Speed

| Differentiator | Technical Implementation | Client Impact |

|---|---|---|

| 14 Senior Metrologists |

• Level 3 PC‑DMIS / CALYPSO certified • 10+ years in aerospace/medical metrology • Dedicated domain specialists (e.g. GD&T, SPC) |

Expertise depth for complex features: - Thin walls (0.2 mm tolerance) - Deep bore reach (300 mm+) |

| 24/7 Emergency Support |

• Git‑versioned program repository • 3‑hr ECO revision SLA • Global time‑zone coverage (EU / NA / APAC) |

Redesigned 10 inspection programs overnight for aerospace supplier - zero line stoppage |

| Multi‑Platform Integration | Legacy controller emulation (RS‑232 / HP‑UX) | Seamless retrofit for 15‑yr old Mitutoyo CMMs |

Ready to get started?

Frequently Asked Questions about CMM Programming

We replicate your exact CMM environment in simulation software (PC-DMIS/CALYPSO), including:

Machine volumetric errors

Probe/stylus configuration

Temperature compensation curves

Yes. We maintain libraries for:

Brown & Sharpe Validator (RS-232)

Zeiss UMM500 (DOS-based)

Mitutoyo Mitu-1 (pre-2000)

Provide your machine's serial number for compatibility verification.

Native CAD: CATIA V5/V6, SOLIDWORKS, NX, Creo

Neutral: STEP AP242, IGES, Parasolid, JT

Note: GD&T callouts must be in model or separate PDF.

Enterprise-grade protocols:

AES-256 encrypted transfers

NDAs executed before project start

Automatic data purging after 30 days

Critical ECO response:

1. Email revised CAD + change notice

2. We prioritize in 3-hr SLA

3. Deliver updated program + delta report

4. 24/7 support hotline for deployment

Secure package includes:

Machine-ready program file (.PRG or .DMIS)

Setup sheet with probe alignment

Virtual run video (MP4)

Access via encrypted portal or physical media.