About Gear Manufacturing

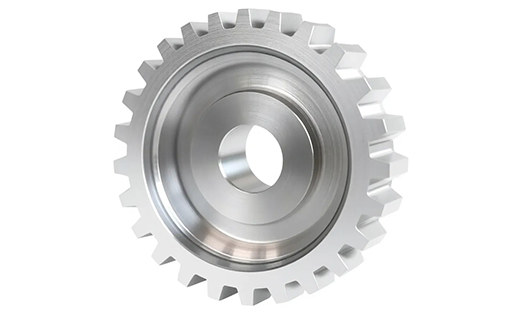

Gear manufacturing encompasses a range of specialized processes to produce precision gears for industries like automotive, aerospace, robotics and industrial machinery. It begins with selecting materials - common options include steel alloys for strength, cast iron for durability, brass/bronze for corrosion resistance and engineered plastics (e.g., Nylon, PEEK) for lightweight or low-noise applications. Key production methods include subtractive techniques like gear hobbing (for spur/helical gears), shaping (internal/cluster gears) and CNC Machining, as well as forming processes such as forging, casting and powder metallurgy. For high-precision or heavy-load applications, secondary finishing - like grinding, lapping or heat treatment-enhances durability, noise reduction and dimensional accuracy.

Modern advancements include additive manufacturing (3D printing) for rapid prototyping or complex custom gears, alongside AI-driven quality control to ensure compliance with international standards (e.g., AGMA, ISO). Capabilities scale from micro-gears for medical devices to large industrial gears exceeding 10 feet in diameter, with processes tailored to volume, material and performance needs. Whether producing standard spur gears or specialized worm/worm wheel sets, gear manufacturing relies on tightly controlled workflows to achieve the exact tooth profiles, tolerances, and surface finishes critical for seamless power transmission.

Gear Manufacturing Services

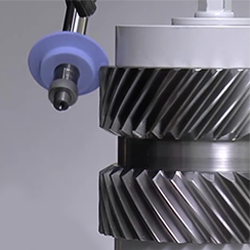

Gear Hobbing

Online QuoteOur manufacturing partners utilize gear hobbing to produce high-precision spur and helical gears with AGMA 12-13 accuracy and Ra 1.6 μm surface finishes in materials from stainless steel to engineering plastics. This high-efficiency process is ideal for volume production, while our platform ensures prototypes in 3 days and batches in 10 days significantly faster than typical platform lead times thanks to our vetted partner network.

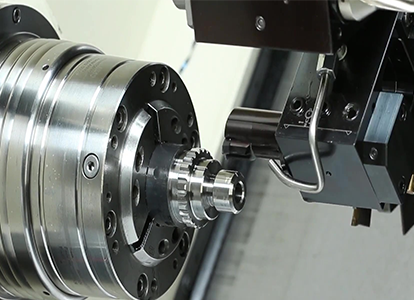

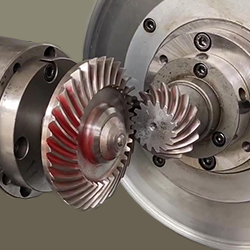

Gear Shaping

Online QuoteFor complex internal gears or cluster gears, our specialized partners employ gear shaping to achieve ±0.025 mm tooth-to-tooth tolerances and DIN 4 quality, even on pre-hardened alloys up to 60 HRC. We streamline access to these niche capabilities through single-point project coordination, eliminating the multi-vendor management required elsewhere for critical applications.

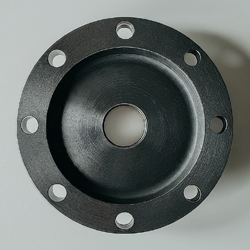

Gear Broaching

Online Quote

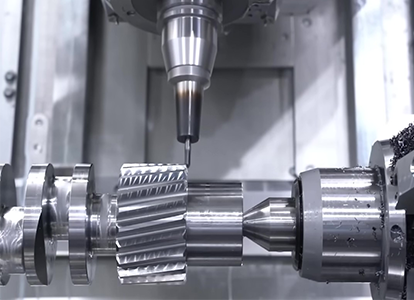

Gear CNC Milling

Online QuoteOur certified partners handle custom gear milling with < 0.02 mm true-position accuracy on 5+ axis machines, supporting alloys, plastics and complex geometries. Through our platform, you get DFM feedback and 5-day prototypes with no minimums combining advanced machining capabilities with platform speed and accessibility.

Gear Tolerances

Leverage our ISO-certified manufacturing partner network to achieve precision-critical gear performance. Each process below delivers standardized tolerances validated through inspection, with expert DFM review in < 6 hours to ensure your designs meet AGMA/DIN targets cost-effectively.

| Feature | Gear Hobbing | Gear Shaping | Gear Broaching | CNC Milling |

|---|---|---|---|---|

| Standard Tolerance Grades | AGMA 11-13 DIN 5-7 |

AGMA 10-12 DIN 6-8 |

AGMA 12-14 DIN 4-6 |

AGMA 9-11 DIN 5-7 |

| Pitch Tolerance | ±0.015 mm (single pitch) | ±0.025 mm (tooth-to-tooth) | ±0.015 mm (total cumulative) | ±0.015 mm (true position) |

| Profile/Helix Tolerance | 8-20 μm | 10-15 μm | 10-15 μm | 20-35 μm |

| Concentricity/Runout | 0.02-0.05 mm | 0.03-0.06 mm | 0.01-0.03 mm | 0.015-0.04 mm |

| Surface Finish (Ra) | 1.6-3.2 μm | 1.6-6.3 μm | 0.8-1.6 μm | 0.4-3.2 μm |

| After Heat Treatment | Grinding required for ≤0.02 mm runout | Limited to ≤60 HRC pre-hardened | Maintains ±0.02 mm at 60 HRC | Stress-relieving recommended |

| Key Tolerance Risks | Thermal distortion in hardening | Residual stress causing bowing | Tool wear affecting form | Tool deflection in thin webs |

| Our Network Advantage | 72-hr AGMA 12 validation | DIN certification included | CMM reports for compliance | 5-axis: ±0.005 mm repeatability |

|

AluminumLightweight, corrosion-resistant, exhibits high strength-to-weight ratio and excellent thermal and electrical conductivity. About Aluminum Available Aluminum AlloysAluminum 6061-T6 Aluminum 6082 Aluminum 7075-T6 Aluminum 5083-H111 Aluminum 6063 |

|

CopperHighly conductive, malleable metal with excellent thermal and electrical conductivity and resistance to corrosion. About Aluminum Available Copper FinishesCopper C101 Copper C110 |

|

Tool SteelHigh hardness, resistance to abrasion and ability to maintain a sharp edge, ideal for cutting and shaping tools. About Tool Steel Available Tool Steel AlloysA2 Tool Steel D2 Tool Steel A3 Tool Steel O1 Tool Steel S7 Tool Steel H13 Tool Steel |

|

Mild SteelMild steel, also known as low-carbon steel. Mild steel is primarily characterized by having a carbon content of less than 0.2% by weight. About Mild Steel Available Iron AlloysMild Steel 1018 Mild Steel 1045 Mild Steel A36 |

|

ThermoplasticsLightweight, strong, corrosion-resistant plastic known for its high strength-to-weight ratio and biocompatibility. About Thermoplastics Available Thermoplastic AlloysPOM PEEK Nylon (PA) Poly Carbonate |

|

Gear GrindingImproves tooth profile and surface finish. Removes small variations in gear teeth. Benefits

|

|

Gear LappingImproves the accuracy, surface finish of gear teeth and corrects the minute errors in gear profiles. Benefits

|

|

GalvanizationA protective zinc coating applied to iron or steel to prevent rusting. Benefits

|

|

Black OxideOffers rust protection, reduces reflectivity and improves aesthetics. Learn more Benefits

|

|

Electroless PlatingEnhances the wear and corrosion resistance with uniform coating thickness. Learn more Benefits

|

Gear Manufacturing Design Guidelines

Navigating gear process limitations is complex especially when sourcing fragmented capabilities across generalist platforms. Our ISO-certified partner network specializes in each technique below, with expert engineers reviewing your uploads in <6 hours. Leverage these guidelines to optimize cost and lead time, then let our platform handle partner matching, quality validation and unified logistics.

| Feature | Gear Hobbing | Gear Shaping | Gear Broaching | CNC Milling |

|---|---|---|---|---|

| Best For | External spur/helical gears | Internal/cluster gears | Internal splines/keyways | Custom/bevel/atypical gears |

| Size Range | Ø10-500 mm | Ø20-300 mm | Ø5-250 mm | Ø5-1000 mm+ |

| Tolerances (AGMA) | 11-13 | 10-12 | 12-14 | 9-11 |

| Face Width Max | 150 mm | 100 mm | 120 mm | No limit |

| Material Suitability | Steel, brass, nylon | Steel (≤60 HRC), brass | Steel (≤60 HRC post-hardening) | All (Inconel, Ti, PEEK, composites) |

| Volume Efficiency | High-volume | Mid-volume | Mass production | Prototypes/low-volume |

| Key Considerations | No undercuts/blind holes | Avoid tight corner radii | Uniform tooth depth required | Draft angles >3° preferred |

| Tooling Lead Time | 2-5 days (std. hobs) | 3-7 days | 7-14 days (custom broaches) | None (digital toolpaths) |

| Our Network Edge | 72-hr prototypes | Single-setup clusters | Hardening included | 5-axis complexity; 5-day delivery |

Clarwe's Quality & Certifications Guarantee

All parts are validated in-house: Clarwe's Guarantee of Zero-Defect Parts

Every component is sourced from our vetted ISO/AS-certified manufacturing partners, then 100% physically inspected at our facility before shipment. Unlike others, we enforce a 3-stage custody protocol:

| Material Compliance: | We order and validate material certifications (RoHS, REACH, mill test reports) on your behalf. |

| In-House Verification: |

Dimensional accuracy checks via CMM, VMM, 2D height gauges and precision tools. Critical feature validation against your drawings (hole positions, thread fits, flatness). Visual inspection for surface defects, burrs and cosmetic flaws. |

| Final Certification: | Full documentation including material certs, CoCs and inspection logs. |

| We guarantee: | ±0.020 mm tolerances on all

shipped parts (validated in-house). Zero paperwork gaps - we manage all supplier certifications. 100% physical custody - no direct supplier shipments delivering zero-defect compliance from prototype to 100,000+ part production runs. |

Why Choose Clarwe Gear Manufacturing Services?

Choose our platform for seamless access to the industry's largest network of ISO 9001:2015-certified gear specialists, rigorously vetted for capabilities in hobbing, shaping, broaching and CNC milling. Our partners deliver certified precision-from AGMA 12 spur gears to ±0.015 mm broached splines-with full material traceability and compliance for aerospace, automotive and medical applications. Unlike fragmented platforms, we provide single-point accountability: your project is managed end-to-end by our technical team, ensuring specifications like DIN 4 tolerances or 60 HRC hardening are met without vendor coordination hassles.

Experience manufacturing simplicity through our intuitive dashboard, featuring online quoting, real-time order tracking and DFM feedback-turning complex gear requests into streamlined workflows. Backed by quality guarantee on every order, we combine the agility of on-demand production with the reliability of enterprise-grade manufacturing. Get precision you can trust, not just speed: where competitors offer basic machining, we deliver certified gear solutions engineered for performance.

Clarwe's Platform Advantage

Our integrated dashboard delivers end-to-end project command-streamlining workflows while ensuring transparency at every stage. Experience seamless coordination from initial request to final delivery, all within a single secure interface.

Submit & Configure

| RFQ Initiation |

Upload CAD files (STEP, IGES, SLDPRT) and drawings Specify requirements: materials, tolerances, finishes, inspection protocols Request custom documentation: material certs, CMM reports, customs forms |

| Real-Time Quoting |

Receive online DFM analysis with cost drivers flagged Adjust configurations (e.g., material substitutions) to optimize pricing |

Order Execution & Oversight

| Document Management |

Submit customs declarations, commercial invoices and HS codes Upload purchase orders or approve terms for payment Access digital invoices with tax/line-item breakdowns |

| Production Intelligence |

Track progress and updates View Shop floor photos/videos Access Inspection reports, quality documents and Material certifications Monitor shipping status with carrier integrations |

Proactive Collaboration & Support

| Engineer Engagement |

Send technical queries and status enquiries to our engineers via encrypted chat Receive resolution timelines for technical queries |

| Quality Assurance Hub |

Access pre-shipment documentation: First-article inspection reports, dimensional reports and quality

documents Approve/reject deliverables via annotated media |

| Post-Delivery Excellence |

Initiate reorders with one-click cloning Log support tickets for non-conformances Archive project history (drawings, certs, comms) for audits |

Industries specialized

Aerospace

Automotive

Consumer Products

Medical

Ready to get started?

Frequently Asked Questions about Gear Manufacturing

Our ISO-certified specialists deliver industry-leading precision:

Yes. Partners hold ISO 9001:2015, AS9100 and ISO 13485 certifications. We provide:

Absolutely. Our network includes:

No. Unlike traditional shops:

| Process | Supported Materials |

|---|---|

| Hobbing/Shaping | Steel (≤60 HRC), Brass, Cast Iron |

| Broaching | Hardened Alloys (up to 60 HRC) |

| CNC Milling | Exotics: Titanium, Inconel, PEEK |

We specialize in producing a wide range of precision gears, including spur gears, helical gears, bevel gears, worm gears, internal gears, splines and custom gear systems. Our manufacturing partners utilize processes like hobbing, shaping, broaching and CNC milling to accommodate prototypes, low-volume batches and high-volume production runs across industries such as automotive, aerospace, medical and robotics.

Our ISO-certified manufacturing partners adhere to international standards such as AGMA, DIN and ISO, ensuring exceptional precision across all processes. For example, gear hobbing achieves AGMA 11-13 tolerances with pitch accuracy within ±0.015 mm, while broaching can hold ±0.015 mm cumulative error and AGMA 12-14 grades. All critical gears include inspection reports validating pitch, profile and concentricity tolerances to meet even the most stringent application requirements.

Prototypes are typically delivered in as little as 3 days for processes like hobbing and broaching and 5 days for CNC milling or shaping. Production batches for larger quantities-including heat treatment and finishing-are completed within 10-15 days. Our platform streamlines partner matching and project management, ensuring faster lead times compared to self-sourced manufacturing solutions.

Yes. Our partners offer end-to-end solutions that include heat treatment processes such as carburizing, induction hardening and nitriding, achieving hardness levels up to 60 HRC. We also provide finishing services like grinding, lapping and honing to enhance gear performance, reduce noise and ensure dimensional stability post-hardening.

We work with a broad range of materials, including carbon and alloy steels, stainless steel, brass, bronze, cast iron and engineering plastics like Nylon, PEEK and Delrin. For high-performance applications in aerospace or medical industries, exotic materials such as titanium and Inconel can be machined using our CNC milling capabilities.

Every gear order undergoes rigorous quality checks via CMM, gear analyzers and surface roughness testers. We provide full inspection reports with each shipment and our 48-hour quality guarantee ensures that any non-conformance is addressed promptly. Our manufacturing partners are ISO 9001, AS9100 or ISO 13485 certified, guaranteeing compliance with industry-specific standards.

Absolutely. Our CNC milling and shaping capabilities are ideal for custom, non-standard or complex gear geometries-including gears with undercuts, thin webs or atypical tooth profiles. Upload your design to our platform for DFM feedback and our engineering team will provide suggestions to optimize the design for manufacturability and performance.

Our intuitive dashboard allows you to upload design files (STEP, IGES, etc.) for online quoting, receive automated design-for-manufacturability feedback and track order progress in real time. With dedicated single-point support, we manage all communications with manufacturing partners, simplifying logistics and ensuring seamless project execution.

No. We cater to both prototype and production needs with no minimum order requirements, even for processes like broaching and shaping that traditionally involve high tooling costs. This flexibility makes our services ideal for startups and enterprises alike.

We have a dedicated engineering team for gear manufacturing and have partnered with specialized, ISO-certified experts to deliver higher precision, faster lead times and deeper technical expertise. With features like integrated heat treatment, guaranteed tolerances and comprehensive inspection reports, we provide an end-to-end solution.