About Electrical Discharge Machining (EDM)

EDM Services

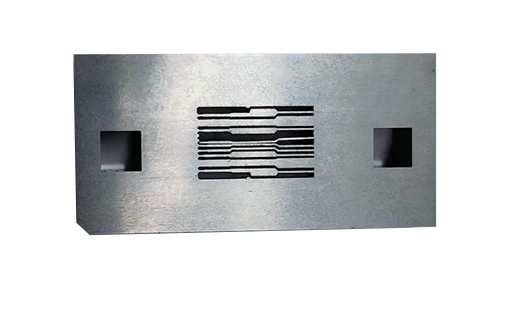

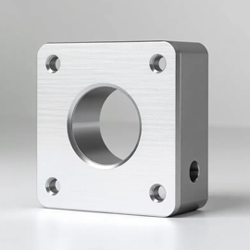

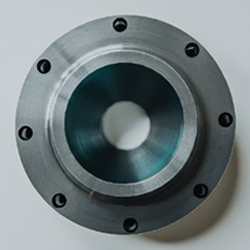

Wire EDM Services

Online Quote

Our precision Wire EDM services deliver exceptional accuracy for complex 2D and 3D geometries, achieving tolerances as tight as 0.0025 mm in materials ranging from hardened tool steels and carbides to aerospace alloys. We ensure burr-free, stress-free cuts with fine surface finishes-ideal for components like medical implants, precision tooling and aerospace actuators.

ISO 9001/AS9100 Certified - Full quality compliance and material traceability

Fast Turnarounds - prototypes in days, production scaling to 50k+ parts

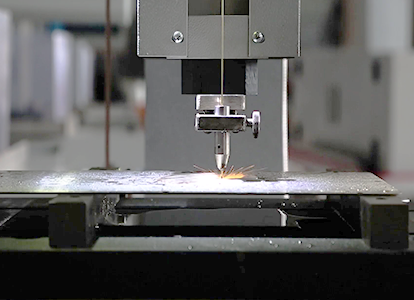

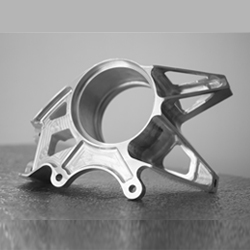

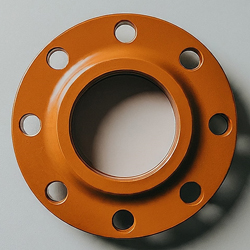

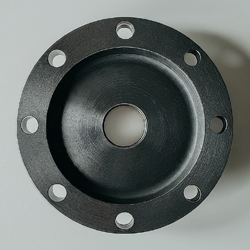

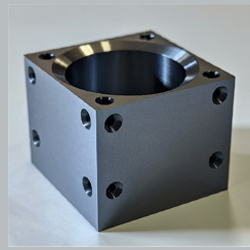

Sinker/Ram EDM Services

Online Quote

Our Sinker/Ram EDM services specialize in producing complex cavities, textures and precise micro-features with exceptional dimensional stability and superior surface finishes as fine as Ra 4 µin. Using custom-shaped graphite or copper electrodes, tolerances of ±0.00015" (3.8 µm) is achieved in hardened metals like tool steels, Inconel® and carbides-making this process ideal for injection molds, aerospace components and high-wear automotive tooling.

ISO 9001/AS9100 Certified - Guaranteed quality and full compliance

Rapid Prototyping & Production - Scalable solutions from 1 to 10,000+ parts

EDM Hole Drilling Services

Online Quote

Our EDM Hole Drilling services specialize in producing high-aspect-ratio micro-holes as small as 0.04 mm (40 µm) with depth-to-diameter ratios up to 30:1, even in the toughest materials like carbides, Inconel® and hardened steels. This process eliminates tool deflection, work hardening and residual stress-making it ideal for aerospace fuel nozzles, medical device lubrication channels and precision mold cooling systems. We deliver burr-free, precision holes with exceptional repeatability for both prototyping and production volumes.

Micro-Holes to 0.04 mm - Precision drilling for highly detailed components

Aspect Ratios Up to 30:1 - Deep, narrow holes in superalloys and carbides

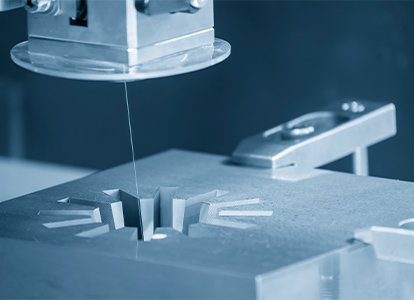

Fine Wire EDM Services

Online Quote

Our Fine Wire EDM services deliver precision for manufacturing complex miniature components using ultra-fine wires as thin as 0.02 mm (20 µm). This advanced process achieves exceptional tolerances within ±0.00004" (1 µm) and produces smooth surface finishes down to Ra 0.1 µm, making it ideal for medical devices, aerospace sensors and precision tooling. With the capability to machine fragile and hard-to-cut materials without inducing mechanical stress or distortion, Fine Wire EDM ensures accuracy and repeatability for highly specialized applications.

Full ISO Certification & Traceability - Quality assured for regulated industries

EDM Tolerances for Precision Applications

To ensure first-pass success and cost efficiency, adhere to these industry-leading tolerance standards for EDM processes. Exceeding these thresholds may require design adjustments or secondary operations, consult our engineers for critical applications.

| EDM Process | Standard Tolerance | Tight Tolerance | Critical Notes | Ideal Materials |

|---|---|---|---|---|

| Wire EDM | ±0.010 mm | ±0.004 mm | Corner radii ≥0.1 mm; Max thickness: 300 mm | Hardened steels, Ti, carbide |

| Sinker/Ram EDM | ±0.010 mm | ±0.004 mm | Surface finish: 4-8 Ra µin; Min feature: 40 µm | Tool steels, Inconel®, copper |

| EDM Hole Drilling | ±0.010 mm | ±0.005 mm | Min Ø: 40 µm; Max depth ratio: 30:1 | Carbide, Hastelloy® |

| Fine Wire EDM | ±0.010 mm | ±0.005 mm | Min feature: 20 µm; Max thickness: 20 mm | Nitinol, beryllium copper |

EDM Materials

|

Aluminum Aluminum CNC MachiningAluminum is a widely utilized material in CNC EDM for both prototyping and manufacturing due to its excellent electrical conductivity and high machinability. Its properties ensure high manufacturability in electrical discharge machining processes, allowing for the precise fabrication of complex components with fine details and tight tolerances. This makes aluminum a preferred choice for a broad range of EDM applications. About Aluminum Available Aluminum AlloysAluminum 6061-T6 Aluminum 6082 Aluminum 7075-T6 Aluminum 5083-H111 Aluminum 6063 Aluminum 5052 Aluminum 2024-T351 Aluminum 7050 Aluminum 2017A Aluminum 6082-T651 Aluminum 7075-T651 Aluminum 2014 Aluminum 6061-T651 Aluminum 7075-T7351 Aluminum 6082-T6 Aluminum 2014-T6 Aluminum 2024-T351 Aluminum 6063-T5 Aluminum 6063-T6 Aluminum 5083-H32 Aluminum 5052-H32 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Anodizing Electroless Nickel Plating Chromate Conversion Coating |

|

Copper Copper CNC MachiningCopper is a highly conductive material widely used in CNC EDM for prototyping and manufacturing applications, offering excellent machinability and manufacturability for complex geometries and fine details. Its superior electrical conductivity ensures efficient spark erosion in both sinker and wire EDM processes, enabling precise feature creation and tight tolerances in production components. Copper electrodes are particularly valued for their durability and ability to achieve mirror-like surface finishes. About Copper Available Copper AlloysCopper C101 Copper C110 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

Brass Brass CNC MachiningBrass is a versatile copper-zinc alloy commonly machined using CNC EDM for both prototyping and manufacturing. It offers good electrical conductivity and excellent machinability, allowing for efficient material removal and high-quality surface finishes in electrical discharge machining processes. These properties ensure reliable manufacturability for producing complex parts with precision and fine detail. About Brass Available Brass AlloysCopper C360 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating |

|

Bronze Bronze CNC MachiningBronze, a copper-tin alloy, is well-suited for CNC EDM processes in both prototyping and production part manufacturing. It provides good electrical conductivity and high wear resistance, which contributes to its excellent machinability and overall manufacturability in electrical discharge machining. These properties allow for the precise fabrication of durable components with complex geometries and fine details. About Bronze Available Bronze Alloys932 Bearing Bronze 954 Bearing Bronze 544 Bearing Bronze As Machined Media Blasting Hand Polishing |

|

Tool Steel Tool Steel CNC MachiningTool steel is a high-carbon alloy ideal for CNC EDM manufacturing, particularly for creating durable molds, dies and production tooling. While its hardness can challenge conventional machining, it offers excellent manufacturability in electrical discharge machining processes. This allows for the precise machining of complex features and tight tolerances in even the hardest pre-hardened states, making it a fundamental material for both prototyping and end-use part manufacturing. About Tool Steel Available Tool Steel AlloysA2 Tool Steel D2 Tool Steel A3 Tool Steel O1 Tool Steel S7 Tool Steel H13 Tool Steel As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

Stainless Steel Stainless Steel CNC MachiningStainless steel is a highly versatile material commonly processed through CNC EDM for both prototyping and manufacturing applications. Known for its excellent corrosion resistance and strength, it maintains good machinability in electrical discharge machining processes. This allows for the precise fabrication of complex, high-tolerance components, ensuring reliable manufacturability for demanding industrial parts. About Stainless Steel Available Stainless Steel AlloysStainless Steel 304 Stainless Steel 316 Stainless Steel 303 Stainless Steel 416 Stainless Steel 2205 Stainless Steel 420 Stainless Steel 440C Stainless Steel 430 Stainless Steel 301 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide Electroless Nickel Plating Electropolishing |

|

Alloy Steel Alloy Steel CNC MachiningAlloy steel is a strong material frequently utilized in CNC EDM for demanding prototyping and manufacturing applications. Its enhanced mechanical properties, including high strength and hardness, are effectively managed through electrical discharge machining, which ensures strong manufacturability for complex parts. This process allows for the precise machining of complex features and tight tolerances in various hardened conditions, making it suitable for durable industrial components and tooling. About Alloy Steel Available Alloy Steel AlloysAlloy Steel 4140 Alloy Steel 4340 Alloy Steel 1215 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

Mild Steel Mild Steel CNC MachiningMild steel is a common low-carbon steel suitable for CNC EDM prototyping and manufacturing. It offers good machinability and consistent performance in electrical discharge machining processes, ensuring reliable manufacturability for a wide range of components. This makes it a practical choice for producing functional parts and prototypes with complex geometry and precise tolerances. About Mild Steel Available Mild Steel AlloysMild Steel 1018 Mild Steel 1045 Mild Steel A36 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide Electroless Nickel Plating |

|

Titanium Titanium CNC MachiningTitanium is a high-strength, low-weight material frequently machined using CNC EDM for demanding prototyping and manufacturing applications. While its toughness challenges conventional machining, it offers excellent manufacturability in electrical discharge machining processes. This allows for the precise fabrication of complex, high-tolerance components with fine details, making it a preferred choice for aerospace, medical and high-performance industrial parts. About Titanium Available Titanium AlloysTitanium Grade 1 Titanium Grade 2 Titanium Grade 5 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

As Machined StandardAs Machined is the standard finish for CNC and EDM parts, leaving a visible tooling pattern with no additional post-processing. This functional surface finish is suitable for parts where aesthetics is not a primary concern. Learn more Finish Specifications

|

|

As Machined MediumThe As Machined Medium finish provides a uniform surface from CNC or EDM machining with reduced but still visible tool marks and a typical surface roughness. This standard, unmachined finish offers a balance between production speed and part aesthetics. Learn more Finish Specifications

|

|

As Machined FineThe As Machined Fine finish from CNC or EDM processes produces a smooth surface with minimal visible tool marks and a lower surface roughness (Ra), requiring no additional post-processing. This fine machined finish is ideal for functional prototypes and parts requiring tighter tolerances. Learn more Finish Specifications

|

|

Bead BlastingBead blasting uses fine glass beads and compressed air to create a uniform, matte texture, removing minor tool marks and providing a consistent, non-abrasive surface preparation for further finishing. Learn more Finish Specifications

|

|

BrushedBrushed finish is achieved by applying abrasive brushing to the metal surface, generating a consistent linear grain pattern often used for decorative or aesthetic purposes. Learn more Finish Specifications

|

|

Chromate Conversion CoatingChromate conversion coating is a chemical process that creates a corrosion-resistant layer on metals like aluminum or zinc, offering mild protection and an electrically conductive, iridescent gold or clear finish. Learn more Finish Specifications

|

|

PolishingPolishing is a mechanical process that removes surface irregularities through abrasion and friction, resulting in a smooth, highly reflective finish that improves visual appeal and corrosion resistance. Learn more Finish Specifications

|

|

Powder CoatingPowder coating is an electrostatic process that applies a dry polymer powder, which is then heat-cured to form a durable, uniform and corrosion-resistant protective layer for both functional and decorative purposes. Learn more Finish Specifications

|

|

Black OxideBlack oxide is a chemical conversion coating that creates a matte black surface for mild corrosion resistance and dimensional stability, without adding significant thickness to the part. Learn more Finish Specifications

|

|

Electroless PlatingElectroless plating is an autocatalytic chemical process that deposits a highly uniform nickel-phosphorus coating for increased corrosion resistance, wear resistance and exceptional hardness without using an electric current. Learn more Finish Specifications

|

|

Anodizing Type 2Anodizing Type II is an electrolytic treatment that produces a controlled aluminum oxide layer on aluminum components, improving corrosion resistance, wear properties and allowing for color dyeing. Learn more Finish Specifications

|

|

Anodizing Type 3 (Hard)Type III hard anodizing is an electrolytic treatment that produces a dense, highly durable aluminum oxide layer, designed to enhance surface hardness and provide excellent corrosion resistance in rigorous applications. Learn more Finish Specifications

|

EDM Design Guidelines

These EDM Design Guidelines ensure your parts are manufactured efficiently and cost-effectively by highlighting critical design constraints and optimization strategies for each process. Adhering to these specifications prevents common manufacturing failures such as wire breakage in Wire EDM, electrode wear in Sinker EDM or hole deflection in Micro-Drilling, while maintaining micron-level tolerances (±0.004 mm) and superior surface finishes. The guidelines directly address material limitations, geometric thresholds and tolerance best practices to eliminate costly redesigns, reduce machining time by up to 30% and guarantee first-pass success for complex geometries in hardened metals, carbides and superalloys.

| Capability | Key Design Guidelines | Why It Matters |

|---|---|---|

| Wire EDM |

• Min corner radius: 0.1 mm • Max thickness: 300 mm • Min slot width: 0.25× material thickness • Avoid aspect ratios >20:1 |

Prevents wire breakage, reduces machining time by 30%, maintains ±0.004 mm accuracy |

| Sinker/Ram EDM |

• Electrode clearance: 0.03-0.1 mm/side • Draft angles: ≥1° • Max cavity depth: 150 mm • Uniform wall thickness |

Lowers electrode costs 40%, achieves Ra 0.8 µin finishes, prevents undercuts |

| EDM Hole Drilling |

• Min hole Ø: 40 µm • Max depth ratio: 30:1 • Entry surface flatness: ±0.1° • Space holes ≥3× diameter |

Eliminates secondary operations, maintains ±10 µm positional accuracy in superalloys |

| Fine Wire EDM |

• Min feature size: 20 µm • Max material thickness: 20 mm • Avoid unsupported spans >5 mm • Specify critical zones for Ra<0.1 µm |

Enables burr-free medical components, reduces fragile-part rejection by 90% |

Clarwe's Quality & Certifications Guarantee

All parts are validated in-house: Clarwe's Guarantee of Zero-Defect Parts

Every component is sourced from our vetted ISO/AS-certified manufacturing partners, then 100% physically inspected at our facility before shipment. Unlike others, we enforce a 3-stage custody protocol:

| Material Compliance: | We order and validate material certifications (RoHS, REACH, mill test reports) on your behalf. |

| In-House Verification: |

Dimensional accuracy checks via CMM, VMM, 2D height gauges and precision tools. Critical feature validation against your drawings (hole positions, thread fits, flatness). Visual inspection for surface defects, burrs and cosmetic flaws. |

| Final Certification: | Full documentation including material certs, CoCs and inspection logs. |

| We guarantee: | ±0.020 mm tolerances on all

shipped parts (validated in-house). Zero paperwork gaps - we manage all supplier certifications. 100% physical custody - no direct supplier shipments delivering zero-defect compliance from prototype to 100,000+ part production runs. |

Why Partner With Clarwe for Precision EDM Services?

We deliver wire EDM, sinker/ram EDM, hole drilling and fine wire EDM capabilities that transcend industry standards, combining micron-level accuracy (±0.004 mm) with unmatched material expertise for hardened steels, carbides and aerospace alloys. Our dedicated team of EDM engineers and ISO 9001/AS9100-certified manufacturing partners ensure consistent quality for complex geometries-from micro-hole drilling (40 µm diameter) to fine wire EDM cutting at 50 µm precision-all backed by rigorous in-process CMM verification and full material traceability. Every project is managed through our intuitive digital dashboard, giving you real-time order tracking, online revision approvals and downloadable inspection reports without navigating opaque platforms.

We guarantee zero burrs, zero distortion and zero supply-chain surprises: if any part fails to meet specifications, we remake it immediately at our cost with expedited shipping. Experience seamless scaling from 1 prototype to 10,000+ production units, all adhering to medical (ISO 13485) and aerospace (AS9100) compliance with lead times 30% faster than industry averages.

Clarwe's Platform Advantage

Our integrated dashboard delivers end-to-end project command-streamlining workflows while ensuring transparency at every stage. Experience seamless coordination from initial request to final delivery, all within a single secure interface.

Submit & Configure

| RFQ Initiation |

Upload CAD files (STEP, IGES, SLDPRT) and drawings Specify requirements: materials, tolerances, finishes, inspection protocols Request custom documentation: material certs, CMM reports, customs forms |

| Real-Time Quoting |

Receive online DFM analysis with cost drivers flagged Adjust configurations (e.g., material substitutions) to optimize pricing |

Order Execution & Oversight

| Document Management |

Submit customs declarations, commercial invoices and HS codes Upload purchase orders or approve terms for payment Access digital invoices with tax/line-item breakdowns |

| Production Intelligence |

Track progress and updates View Shop floor photos/videos Access Inspection reports, quality documents and Material certifications Monitor shipping status with carrier integrations |

Proactive Collaboration & Support

| Engineer Engagement |

Send technical queries and status enquiries to our engineers via encrypted chat Receive resolution timelines for technical queries |

| Quality Assurance Hub |

Access pre-shipment documentation: First-article inspection reports, dimensional reports and quality

documents Approve/reject deliverables via annotated media |

| Post-Delivery Excellence |

Initiate reorders with one-click cloning Log support tickets for non-conformances Archive project history (drawings, certs, comms) for audits |

Industries specialized

Aerospace

Automotive

Consumer Products

Medical

Ready to get started?

Frequently Asked Questions about CNA EDM

We specialize in Wire EDM (precision 2D/3D contouring), Sinker/Ram EDM (complex cavities/textures), EDM Hole Drilling (micro-holes down to 40 µm) and Fine Wire EDM (20 µm feature resolution). Our multi-process approach handles everything from aerospace turbine components to medical micro-implants, achieving tolerances to ±0.004 mm.

We machine 50+ conductive materials, including hardened tool steels (D2, H13), titanium, Inconel®, carbide, copper. Unlike competitors, we excel with alloys for medical (ISO 13485) and aerospace (AS9100) applications, with thicknesses up to 600 mm for Wire EDM.

We guarantee 30% tighter tolerances than industry averages:

Yes. Our engineers offer free DFM analysis within 4 hours, optimizing designs to avoid costly errors. Key guidelines include:

We specialize in:

Every part undergoes:

1. In-process CMM checks during machining.

2. Final inspection with optical comparators.

3. Full traceability with material certifications.

We exceed ISO 9001:2015 standards and provide inspection reports with shipments.

Absolutely. Leveraging our network of 200+ ISO-certified partners, we scale from 1 prototype to 50,000+ production parts with consistent quality. Lead times are 30% faster than other providers for identical orders.

Upload STEP, IGES, DXF or SolidWorks® files for online pricing. For 2D drawings, include GD&T callouts and surface finish requirements (e.g., Ra 0.8 µin). Our platform analyzes designs in <5 minutes with free DFM feedback.

Yes. We provide anodizing, powder coating, micro-arc oxidation (MAO) and electropolishing. All finishes meet industry-specific requirements (e.g., corrosion resistance for marine components).

Get a Online Quote in 2 Hours: by [uploading your CAD file](link).

We promise:

On-time delivery: 99.7% success rate (vs. 95% industry average).

Zero-surprise pricing: All costs locked pre-production.

Quality commitment: Remake parts at our cost if specs are missed.