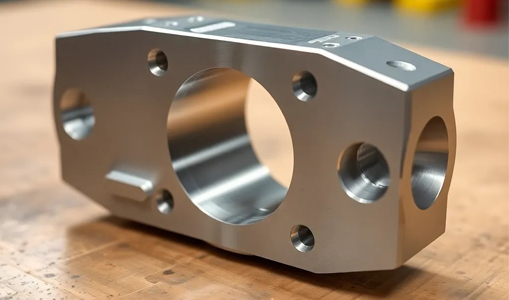

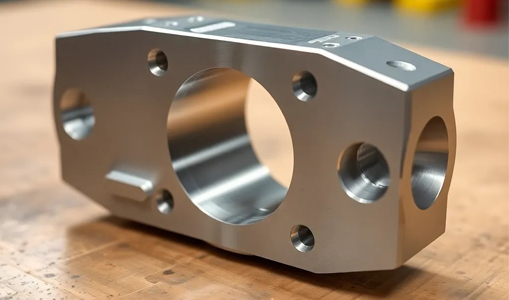

As-machined (fine) surface finish is achieved through precision machining processes with carefully optimized cutting parameters, resulting in a smoother and more refined surface. This finish features minimal and less pronounced tool marks due to reduced feed rates, higher spindle speeds and sharp cutting tools. Surface roughness typically ranges from 0.8 to 1.6 µm Ra, depending on the material properties and machine tool capabilities. Fine surface finishes enhance dimensional accuracy and surface integrity, making them suitable for tight tolerance applications and critical mating surfaces. This level of finish reduces the need for secondary finishing processes while still meeting high-performance and functional requirements. It helps minimize friction, wear and potential stress concentrations in moving components. Slight burrs may still occur but are minimal due to precise tool control. Common applications includeaerospace ,medical devices and high-performancemechanical assemblies . Fine as-machined finishes provide a balance between aesthetic quality and mechanical function without the added cost of post-processing.

All metals like (Aluminum ,stainless steel etc.) and someplastics.

Typically " Ra 0.8μm / Ra 32μin" with slight visible tool marks.

Smooth, with minor tool marks.

Not cosmetic; no finishing or smoothing applied.

No change in material thickness; true to machined dimensions.

Uniform with fine tool path lines.

6061 T6, 6082, 7075-T6, 5083-H111, 6063, 5052, 2024-T351, 7050, 2017A, 6082-T651, 7075-T651, 2014, 6061-T651, 7075-T7351, 6082-T6, 2014-T6, 6063-T5, 6063-T6, 5083-H32, 5052-H32

A2 Tool steel, D2 Tool steel, A3 Tool Steel, O1 Tool Steel, S7 Tool Steel, H13 Tool Steel

932 Bearing Bronze , 954 Bearing Bronze, 544 Bearing Bronze

A fine “as machined” surface usually has a roughness of 1.6 μm (63 µin) or better, depending on the material and machining setup.

Fine machining uses slower cutting speeds, sharper tools and sometimes additional tool passes to reduce surface irregularities and achieve a more consistent texture.

Fine machining often coincides with tight tolerance requirements, typically ±0.005 mm to ±0.01 mm, depending on the setup and material.