About CNC Tube Bending

CNC tube bending utilizes computer-controlled machinery to achieve highly precise and repeatable bends in metal tubing. This automated process translates digital designs into complex multi-plane geometries, including tight radii, compound curves and back-to-back bends. It supports a wide range of materials - such as stainless steel, aluminum and copper - across various diameters and wall thicknesses. Precision tooling, often including internal mandrels, maintains cross-section integrity and minimizes deformation, even for thin-walled or high-strength alloys. This capability is essential for producing consistent, high-accuracy tubular components efficiently, meeting exact specifications for prototypes, low-volume runs or complex assemblies across industries.

CNC Tube Bending Capabilities

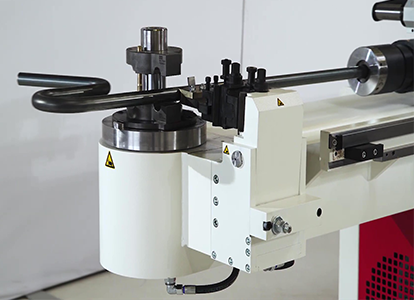

Mandrel Bending

Online Quote

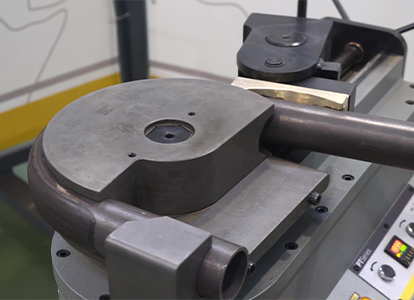

Rotary Draw Bending

Online Quote

High-Precision, Repeatable Bends for Complex Components

Achieve consistent, multi-angle accuracy (±0.1°) with our computer-controlled rotary draw bending process. Using

precision dies and mandrels, we cold-form tubes (OD: 6 mm - 75 mm | Walls: 0.5-4 mm) while maintaining cross-section

integrity across radii from 2×D to 12×D. This method is ideal for applications like exhaust systems, roll

cages and chassis components requiring tight tolerances and repeatability.

Leverage ISO 9001-certified workflows to accelerate production-from rapid prototyping to high-volume runs. We deliver structurally critical parts faster than traditional sourcing, without compromising on precision or quality.

Roll (Push) Bending

Online Quote

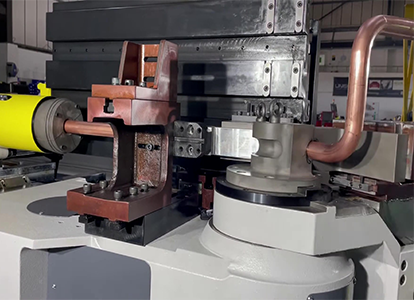

Hybrid Machines

Online Quote

Unmatched Geometric Flexibility for Complex tubular Designs

Experience maximum design freedom with advanced hybrid tube bending technology, which seamlessly integrates rotary draw and roll bending within a single CNC platform which enables the production of multi-radius bends and curves without the need for retooling between operations. Capable of processing tubes from 6 mm to 75 mm OD with wall thicknesses of 0.5-4 mm, this method accommodates both tight radii (as low as 2D) and large sweeping curves (≥7×D) in a single setup.

Our ISO-certified manufacturing partners produce multi-radius components in a single operation for complex prototypes and low-volume production runs.

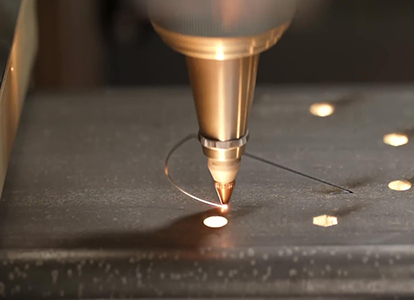

CNC Laser Cutting for Tubular Parts

Online Quote

Precision Preparation for Flawless Bending and Assembly

Multi-axis CNC laser cutting technology delivers ultra-precise, burr-free cuts on tubular structures with complex geometries. This process ensures clean, ready-to-bend components with ±0.5 mm positional and ±0.1 mm dimensional tolerance, eliminating the need for secondary machining and minimizing material waste. Ideal for notching, hole patterning and end-forming on stainless steel, aluminum and alloys, our laser cutting systems prepare tubes up to 75 mm OD.

By integrating laser cutting with our bending capabilities, we offer a streamlined, single-source solution that reduces production steps and accelerates turnaround.

CNC Tube Bending Tolerances

This table shows the typical precision levels for different tube bending methods. Mandrel and Hybrid bending offer the tightest accuracy for demanding projects, like aerospace parts. Rotary Draw bending provides reliable consistency for most industrial needs. Roll bending is ideal for simpler, large-curve applications where ultra-high precision isn't required. All methods ensure trusted performance for your designs.

| Tolerance Parameter | Mandrel Bending | Rotary Draw Bending | Roll (Push) Bending | Hybrid Machines |

|---|---|---|---|---|

| Angular Accuracy | ±0.25° | ±0.5° | ±0.1° | ±0.5° |

| Linear Dimensional | ±0.005" (0.13 mm) | ±0.010" (0.25 mm) | ±0.030" (0.76 mm) | ±0.005" (0.13 mm) |

| Positional (Bend-to-Bend) | ±0.020" (0.5 mm) | ±0.030" (0.76 mm) | N/A | ±0.020" (0.5 mm) |

| Ovality (Cross-Section) | 1.5-3% | 3-5% | 5-8% | 1.5-4% |

| Wall Thinning | ≤10% | ≤15% | ≤20% | ≤12% |

CNC Tube Bending Design Guidelines

Select the optimal bending method for your project using the technical guidelines below. Our ISO-certified network ensures precision across all capabilities, from tight-radius aerospace components to large-scale architectural curves.

| Feature | Mandrel Bending | Rotary Draw Bending | Roll (Push) Bending | Hybrid Machines |

|---|---|---|---|---|

| Min. Bend Radius | 1.5× tube diameter (0.5×D achievable) |

2× tube diameter | 7× tube diameter | 0.5" to 12" (variable) |

| Max. Tube Diameter | 6 - 75 mm | 6 - 75 mm | 6 - 75 mm | 6 - 75 mm |

| Wall Thickness | 0.5 - 4 mm walls | 0.5 - 4 mm walls | 0.5 - 4 mm walls | 0.5 - 4 mm walls |

| Material Compatibility | Stainless, Titanium, Inconel, Aluminum | All metals (inc. chromoly, copper) | Aluminum, Steel, Copper | All metals (incl. exotics) |

| Geometric Complexity | Multi-plane, 180° U-bends | 2D/3D contours, multi-angle bends | Sweeping arcs, large curves | Variable radii, compound curves |

| Tolerance Precision | ±0.5° | ±1° angular accuracy | ±2° (low-tolerance focus) | ±1° (multi-process sync) |

| Typical Applications | Hydraulic lines, fuel systems | Exhausts, roll cages, chassis | Handrails, furniture frames | Engine guards, handlebars |

Clarwe's Quality & Certifications Guarantee

All parts are validated in-house: Clarwe's Guarantee of Zero-Defect Parts

Every component is sourced from our vetted ISO/AS-certified manufacturing partners, then 100% physically inspected at our facility before shipment. Unlike others, we enforce a 3-stage custody protocol:

| Material Compliance: | We order and validate material certifications (RoHS, REACH, mill test reports) on your behalf. |

| In-House Verification: |

Dimensional accuracy checks via CMM, VMM, 2D height gauges and precision tools. Critical feature validation against your drawings (hole positions, thread fits, flatness). Visual inspection for surface defects, burrs and cosmetic flaws. |

| Final Certification: | Full documentation including material certs, CoCs and inspection logs. |

| We guarantee: | ±0.020 mm tolerances on all

shipped parts (validated in-house). Zero paperwork gaps - we manage all supplier certifications. 100% physical custody - no direct supplier shipments delivering zero-defect compliance from prototype to 100,000+ part production runs. |

Why Choose Clarwe CNC Tube Bending Services?

We specialize in precision tube bending, leveraging mandrel bending for aerospace-grade tight radii, rotary draw bending for complex multi-angle accuracy, roll bending for cost-efficient large arcs and hybrid machines for geometrically complex parts. Every order is routed through our vetted, ISO 9001/AS9100-certified manufacturing network, ensuring consistent quality control and compliance for regulated industries like medical and aerospace. This specialization means no compromises: we handle thin-wall titanium fuel lines, thick Inconel heat exchangers and everything between with zero templated workflows.

Beyond technical expertise, we deliver operational simplicity. Our proprietary dashboard enables online quoting, real-time order tracking and seamless communication, turning complex bending projects into intuitive workflows. Combined with our first-pass quality guarantee and material traceability, this eliminates the delays and requotes common with commoditized platforms. You get specialized expertise scaled like a marketplace: dedicated engineering support for DFM feedback, assembly-ready kitting and 30% faster lead times on prototypes to production runs. Precision tubing shouldn't mean trade-offs with us, you gain both specialization and speed.

Clarwe's Platform Advantage

Our integrated dashboard delivers end-to-end project command-streamlining workflows while ensuring transparency at every stage. Experience seamless coordination from initial request to final delivery, all within a single secure interface.

Submit & Configure

| RFQ Initiation |

Upload CAD files (STEP, IGES, SLDPRT) and drawings Specify requirements: materials, tolerances, finishes, inspection protocols Request custom documentation: material certs, CMM reports, customs forms |

| Real-Time Quoting |

Receive online DFM analysis with cost drivers flagged Adjust configurations (e.g., material substitutions) to optimize pricing |

Order Execution & Oversight

| Document Management |

Submit customs declarations, commercial invoices and HS codes Upload purchase orders or approve terms for payment Access digital invoices with tax/line-item breakdowns |

| Production Intelligence |

Track progress and updates View Shop floor photos/videos Access Inspection reports, quality documents and Material certifications Monitor shipping status with carrier integrations |

Proactive Collaboration & Support

| Engineer Engagement |

Send technical queries and status enquiries to our engineers via encrypted chat Receive resolution timelines for technical queries |

| Quality Assurance Hub |

Access pre-shipment documentation: First-article inspection reports, dimensional reports and quality

documents Approve/reject deliverables via annotated media |

| Post-Delivery Excellence |

Initiate reorders with one-click cloning Log support tickets for non-conformances Archive project history (drawings, certs, comms) for audits |

Industries specialized

Aerospace

Automotive

Consumer Products

Medical

Ready to get started?

Frequently Asked Questions about CNC Tube Bending

Our ISO 9001/AS9100-certified network guarantees industry-leading precision:

CAD formats: STEP, IGES, SLDPRT; drawings: PDF, DXF.

We provide four specialized bending techniques to meet diverse design requirements: Mandrel Bending for tight radii and thin-walled tubing (e.g., aerospace fuel lines), Rotary Draw Bending for high-precision multi-angle components (e.g., exhaust systems), Roll Bending for large-radius arcs (e.g., architectural handrails) and Hybrid Machines for complex geometries requiring variable radii. Each method is executed by our ISO 9001/AS9100-certified manufacturing partners, ensuring compliance with industry standards.

Absolutely. As an on-demand manufacturer, we specialize in both prototyping and production runs-from single parts to large batches. Our digital platform provides online quoting and DFM feedback, streamlining the process for projects of any scale.

All work is performed by our vetted network of ISO-certified partners, with strict adherence to AS9100 (aerospace), ISO 13485 (medical). We guarantee full material traceability, real-time production monitoring and quality documentation with every order.

Upload your CAD files (STEP, IGES, SLDPRT) or drawings (PDF, DXF) to our intuitive dashboard for online, automated quoting. Once approved, you'll receive real-time production updates and dedicated engineering support for design optimization.

Yes. Our partners offer end-to-end services including cutting, notching, welding, polishing, anodizing and assembly kitting-ensuring ready-to-install components without multiple vendors.

We support aerospace, automotive, medical, consumer products and industrial sectors, providing compliant solutions for high-integrity applications like hydraulic systems, surgical devices and custom structures.

Yes. Our engineers offer free DFM (Design for Manufacturability) feedback to optimize designs for cost, performance and producibility-before production begins.