About Offline CNC Programming

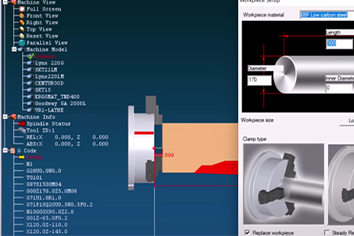

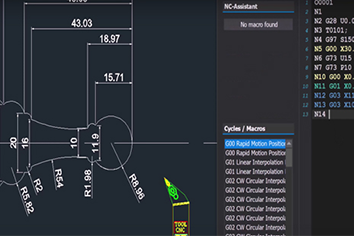

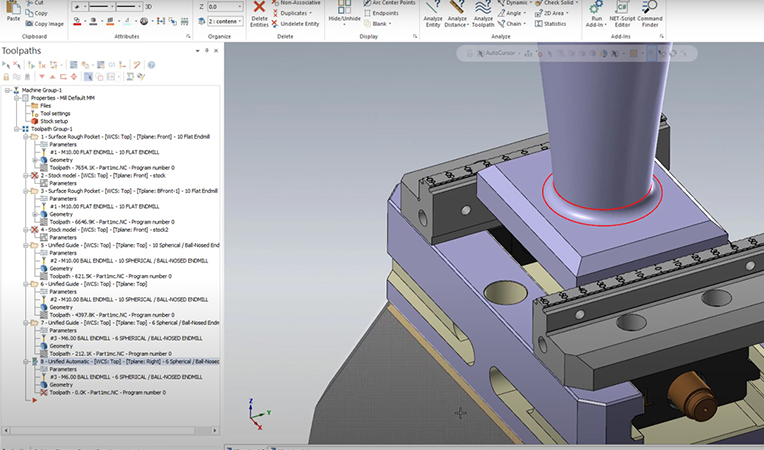

Offline CNC Programming is a sophisticated engineering process where machine instructions (G-code) are generated and optimized remotely from the physical CNC machine, using specialized CAD/CAM software. This begins with importing a 3D CAD model (e.g., STEP, IGES, Parasolid) into a CAM system, where a programmer defines the manufacturing strategy. This involves selecting cutting tools, specifying feed rates and spindle speeds based on material science data and constructing precise, efficient toolpaths such as adaptive roughing, trochoidal milling or multi-axis simultaneous contouring. The core of offline programming is the creation of a universal toolpath file, often called Cutter Location (CL) data, which is then translated into machine-specific G-code through a meticulously configured post-processor. This software component is critical, as it maps generic movements to the exact dialect and kinematic configuration of the target machine controller (e.g., Fanuc, Siemens, Heidenhain).

The paramount advantage of this method is the comprehensive virtual verification cycle. The G-code is put through rigorous simulation software that performs dynamic material removal analysis, full machine kinematics emulation and collision detection-checking for tool-holder-fixture and machine component interferences. This digital twin environment eliminates the risk of catastrophic crashes and first-article scrap by identifying errors in the virtual realm. Furthermore, it allows for advanced optimization of toolpaths to minimize non-cutting air movement, reduce cycle times, manage tool load and extend tool life, resulting in a program that is not only error-free but also engineered for peak efficiency and cost-effectiveness before it ever reaches the shop floor.

Why Outsource Offline CNC Programming?

Offline CNC Programming Solves Your Biggest Production Bottlenecks - Before They Reach the Shop Floor.

| Problem | Solution |

|---|---|

|

The Hidden Costs of In-House Programming When CNC programming is rushed, under-resourced or handled by generalists, it creates a ripple effect of costly problems: Wasted Machine Time: Unoptimized toolpaths increase cycle times by 15-40%, tying up valuable equipment. Scrap & Rework: Undetected errors in G-code (gouging, collisions, tolerance misses) scrap 5-15% of high-value parts. Premature Tool Failure: Poor toolpath strategies accelerate wear, forcing 2-3X more tool changes on hardened steels or composites. Skills Gap Struggles: Complex jobs (5-axis contouring, thin-wall milling) stall without specialized CAM expertise. Version Chaos: Legacy code edits without documentation create reliability risks in repeat jobs. |

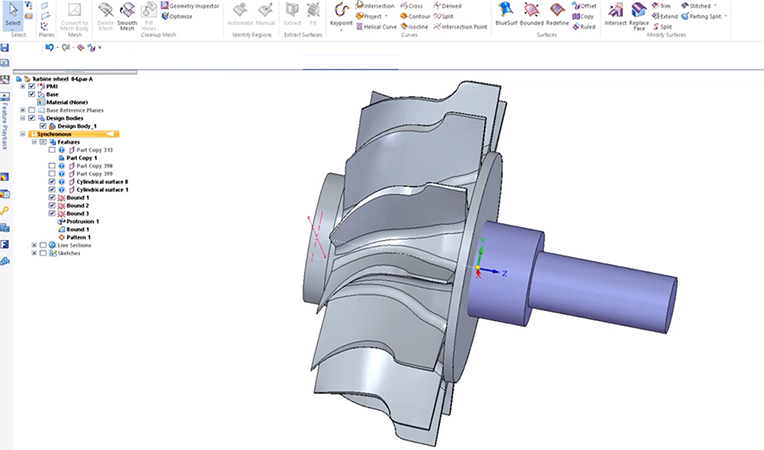

How Clarwe's Offline Programming Eliminates These Risks Our dedicated CNC programmers transform your CAD data into flawless, machine-ready code - all before loading raw material: Cycle Time Reduced: AI-driven toolpath optimization reduces machining time by 15-30% via adaptive toolpaths and strategic roughing/finishing. Zero-Error Guarantee: All code undergoes 3-step verification: Virtual Simulation (material removal + collision checks) Machine-Specific Post-Processing (Fanuc, Haas, Siemens) Tolerance Stack Analysis Tooling Cost Control: Optimal feeds/speeds and tool engagement protect your endmills and inserts, even on Inconel or CFRP. Complex Geometry Mastery: Multi-axis strategies for impellers, blisks and micro-molds with 0.005 mm tolerances. Fully Documented Revisions: Version-controlled G-code with setup sheets, tool lists and operator notes. |

Advanced CNC Programming Capabilities

From 3-Axis Mills to 9-Axis Mill-Turn Centers, We Deliver Production-Ready Code for Your Most Demanding Jobs.

Machines Programmed

We generate optimized G-code for all major CNC platforms, with custom post-processors ensuring flawless machine compatibility:

Specialties: Complex 5-axis contouring (blades, impellers), thin-wall aerospace components, micro-machining (±0.001" tolerances).

Materials Expertise

Proven strategies for 200+ materials, including challenging alloys and composites:

| Category | Examples | Key Solutions |

|---|---|---|

| Aerospace | Inconel 718, Ti-6Al-4V, CFRP | Low-vibration toolpaths, thermal management |

| Medical | 316L Stainless, PEEK, Co-Cr | Micro-toolpaths (<0.5 mm), surface finish Ra<0.4 μm |

| Automotive | A380 Aluminum, Ductile Iron, PMMA | High-speed roughing, minimal fixture passes |

| Special Materials | Tungsten, Ceramic-Matrix Composites | Peck drilling, trochoidal milling |

Comprehensive Service Portfolio

Beyond G-code: End-to-end solutions for seamless production:

| Service | Description | Customer Benefit |

|---|---|---|

| CAD-to-CAM Conversion | Convert STEP/IGES/SLDPRT into machine-ready toolpaths (Mastercam, NX, Fusion 360) | Eliminate software license costs & training |

| G-Code Optimization | Reduce cycle times 15-40% via adaptive toolpaths, trochoidal milling and AI-driven feeds/speeds | Slash machining costs per part |

| Legacy Code Revitalization | Repair/update outdated programs (Fanuc 0i to Haas NGC) | Modernize without reprogramming from scratch |

| Custom Post-Processors | Develop machine-specific posts for Siemens 840D, Mazak Matrix, Okuma OSP | Eliminate manual edits & post bugs |

| Setup Documentation | Generate tool lists, setup sheets and work instructions (PDF/Excel) | Reduce operator setup time by 50% |

| DFM Feedback | Identify design flaws (undercuts, tool access) before machining | Prevent scrap & redesign costs |

Our CNC Programming Services

Offline CNC Programming Services

Online QuoteWe offer CNC Programming services for 3, 4, 5 axis milling centers and 2, 3 axis CNC lathes. Our programmers have vast experience in Fanuc, Siemens, Heidenhain and Haas controllers. Our engineers and programmers are experts in Powermill, MasterCam, NX and Fusion 360. Our team can produce highly optimized NC code to provide significant savings on your CNC manufacturing costs.

We provide comprehensive solutions tailored to client's specific requirements. Clarwe offers secure and seamless collaboration using TeamViewer, to ensure confidentiality.

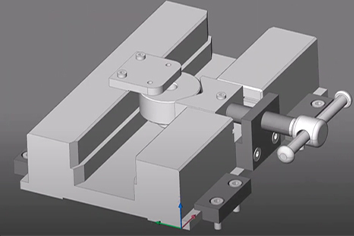

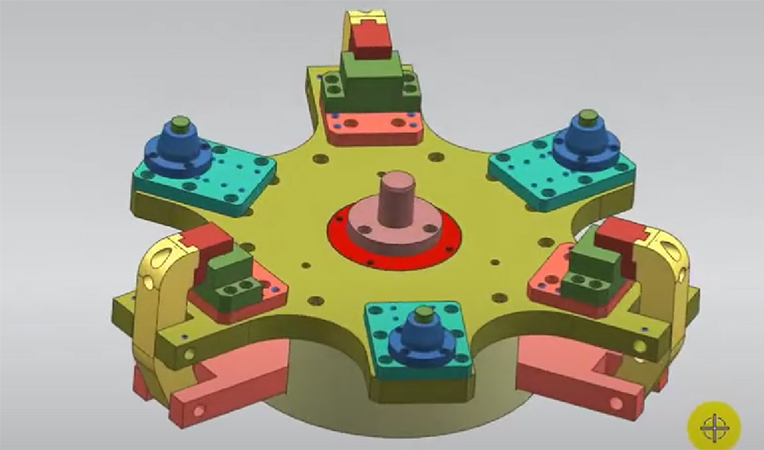

Custom fixturing for every need

Online QuoteOur engineering team can design a wide variety of milling and turning fixtures. When determining the appropriate tooling, we consider factors such as part size, material, machine size, configuration, quantity and the specific operation. For complex CNC fixture designs, we take all these aspects into account to ensure precision and effectiveness.

Custom vice jaws Custom tombstone fixtures JigsStand-alone fixtures Lathe/Turning fixtures

Reverse-Engineered Parts

Online QuoteIf you need to recreate a part without technical drawings, our reverse engineering services can help. Using advanced laser scanners and CAD tools, our reverse engineering services enable us to reproduce replacement parts in a timely and cost-effective manner. All we need is a sample part and we can produce an accurate CAD model and drawings for the part.

Develop a dependable 3D CAD model Recreate outdated or obsolete parts or products Explore designs that can be improved or modified Innovate and refine existing part or product designsCNC Programming in 3 Simple Steps

Step 1: Share Your Design Securely

Send your part file via our encrypted portal. We accept all major formats:

• CAD Files : STEP, IGES, Parasolid, SLDPRT, CATPart, Fusion 360

• Drawings : PDF, DWG (with critical tolerances & finishes)

• Job Details : Material, machine model, controller type, lot size

Need help? Our engineers will contact you within 1 hour to clarify requirements.

All files protected with AES-256 encryption. NDAs signed on request.

Step 2: Expert Programming

Certified programmers (Mastercam/NX) handle your project end-to-end:

• CAD Analysis: DFM check for tool access, thin walls, undercuts

• Toolpath Strategy: Adaptive roughing, optimized finishing, multi-axis contouring

• Machine-Specific Post-Processing: Custom G-code for Fanuc, Haas, Mazak, etc.

Complex jobs? We'll share toolpath previews for your approval.10+ years avgerage programmer experience | ISO 9001-compliant workflow

Step 3: Verification

3-Step Verification:

• Virtual Machining Simulation (collision/travel checks)

• Tolerance Stack Analysis (GD&T validation)

• Post-Processor Dry Run (controller-specific testing)

Free revisions if machine setup reveals issues.

(rare with our 3-step verification!)

Step 4: Receive Production-Ready Files

Get everything you need to start machining:• Machine-Ready G-Code : (.NC, .TAP, .EIA)

• Setup Package :

Tool List (holders, inserts, feeds/speeds)

Setup Sheet (fixturing diagram, work offsets)

Simulation Video (for operator reference)

• Revision Notes : Optimizations applied, critical tolerance callouts

Delivered via secure portal in your preferred format within 24-48 hours.Technical Specifications

Comprehensive Capabilities for Complex Manufacturing Challenges

Machine Programming Expertise| Machine Type | Controllers Supported | Specialized Applications |

|---|---|---|

| 5-Axis Mills | Siemens 840D, Heidenhain TNC640, Fanuc 31i | Impellers, blisks, turbine blades |

| CNC Lathes | Mazak Matrix, Okuma OSP, Haas NGC | Eccentric turned parts, deep boring |

| Mill-Turn | DMG Mori CELOS, Nakamura Tome | Complete part machining in single setup |

| Swiss-Type | Citizen L32, Tsugami B0205 | Medical bone screws, micro-pins (±0.005 mm) |

Material-Specific Strategies

| Material Group | Key Solutions | Surface Finish Capabilities |

|---|---|---|

| Aerospace Alloys (Inconel, Ti) | Thermal management toolpaths, chip thinning control | Ra 0.4-0.8 μm with specialized finishing |

| Medical (PEEK, Co-Cr) | Micro-toolpaths (<0.3 mm), vibration dampening | Mirror finishes (Ra <0.2 μm) for implants |

| Composites (CFRP, G10) | Peel-milling techniques, specialized tool geometries | Delamination-free edges, precise fiber cutting |

File Specifications

Accepted Inputs:

- CAD: STEP, IGES, Parasolid, SLDPRT, CATIA V5

- Drawings: PDF, DWG (with GD&T callouts)

- Legacy: G-code repair/optimization

Output Deliverables:

- G-code: .NC, .TAP, .EIA formats

- Documentation: Setup sheets (PDF), Tool lists (Excel)

- Simulations: Video walkthroughs (MP4)

CNC Programming Applications

Aerospace

- Problem: 5-axis aluminum wing rib with 0.05 mm wall flexing during machining

- Solution: Multi-stage adaptive toolpaths with harmonic dampening

- Result: Zero scrap | 28% faster vs. previous vendor

Medical

- Problem: Titanium spinal implant requiring Ra 0.2 μm finish

- Solution: Trochoidal finishing + specialized tool orientation

- Result: First-pass approval | 40% longer tool life

Automotive

- Problem: High-volume transmission housing (5 k/mo) with 45 min cycle time

- Solution: Optimized tool change sequencing + chip evacuation strategy

- Result: Cycle to 31 min | Saved $2.15/part

Energy

- Problem: Turbine nozzle grinding from legacy 2D drawings

- Solution: 3D CAD reconstruction + 4-axis simultaneous programming

- Result: Eliminated manual polishing | GD&T compliance achieved

Trust & Security

Your Designs Are Protected Throughout Our Workflow

Security Framework

Data Protection

• 256-bit SSL encryption during transfer• Air-gapped workstations for sensitive projects

• Automatic file purging (30-day default, customizable)

Expertise Proof Points

• 600+ parts programmed since 2022• 0.2% revision rate (industry avg: 5-7%)

• 37 certified CAM programmers (avg. 9 yrs experience)

Why Choose Clarwe for CNC Programming?

How Precision Programming Translates to Tangible ROI and Operational Excellence

| Benefit | Technical Explanation | Business Impact |

|---|---|---|

| Cycle Time Reduction | Adaptive toolpaths, optimized stepovers and strategic roughing/finishing transitions | 15-40% faster machining per part = 50+ extra production hours monthly |

| Tooling Cost Savings | Scientifically calculated feeds/speeds + optimal tool engagement angles | Extend endmill life 2-3× on titanium and hardened steels |

| Zero-Scrap Guarantee | Collision-proof simulations + tolerance stack analysis (GD&T validation) | Eliminate $500-$25,000 scrap costs per failed part |

| Setup Time Reduction | Machine-specific setup sheets with fixture diagrams and tool presetter offsets | Reduce operator setup by 45-60 minutes per job |

| IP Protection | AES-256 encryption, auto-file purging (30 days), customizable NDAs | Military-grade security for defense and aerospace projects |

| Capacity Expansion | 24-hour programming turnaround vs. 2-week in-house backlog | Handle 300% more complex jobs without new hires |

Significant cost savings

Gouge & Collision checked

Seamless collaboration

using TeamViewer

Support across all

time zones

Quality Assurance

CAD Analysis

Toolpath Strategy

Machine Simulation

Tolerance Validation

Post-Processor Test

Senior Engineer Sign-off

Ready to get started?

Frequently Asked Questions about CNC Programming

We develop custom post-processors for your exact machine/controller combination (e.g., Haas VF-4SS with NGC). All code is tested in virtual machine environments before delivery.

We provide free revisions for any issues found during first-article inspection. 98% of jobs run perfectly after our 5-stage verification process.

Yes! We digitize 2D drawings into 3D models, adding modern GD&T standards. Additional engineering fees apply ($85-$150/hour).

Absolutely. We program single prototypes (often delivered same-day) with no minimum order requirements.

Based on part complexity, tolerances and machine type. Our prices are 40-50% cheaper than US and Europe. Request a sample quote for your part.

We enforce military-grade security: AES-256 encrypted transfers, NDAs signed before work begins, air-gapped workstations for sensitive projects and automatic file purging 30 days after job completion.

We guarantee machine-ready code through our 5-step verification: 1. Virtual machine simulation 2. Controller-specific post-processor testing 3. Collision mapping 4. Tolerance stack analysis 5. Dry-run validation. If issues arise, we provide free revisions within 24 hours.

Standard delivery: 24-48 hours. We also offer 12-hour rush and 4-hour emergency services.

Absolutely. We specialize in:

- Prototypes: 1-10 pieces (no setup fee)

- Bridge production: 10-500 pieces

- High-volume: 500+ pieces (volume discounts)

Yes to both:

- 2D drawings: We convert to 3D models

- Legacy G-code: We reverse-engineer and optimize

Our certified engineers work in:

- Mastercam (75% of jobs)

- Siemens NX (complex 5-axis)

- Fusion 360 (startups)

- Esprit (Swiss/mill-turn)

Request preferred software in your order notes.

We deploy:

- Thermal compensation toolpaths

- Vibration analysis simulations

- Tool deflection calculations

- Multi-pass finishing strategies

+25% fee for tolerances under ±0.025 mm.

We offer:

- Minor tweaks: Free

- Major revisions

- Full reprogramming at discounted prices

All changes include updated setup documentation.

Yes, our specialized capabilities include:

Micro-toolpaths down to 0.1 mm

Medical bone screw threading

Watch component engraving

Optical lens molds

Requires specialized CAM modules (+$100 fee).

Every job includes:

Machine-ready G-code (.NC/.TAP)

PDF setup sheet with fixture diagram

Excel tool list with feeds/speeds

Simulation video (optional)

Material cutting parameters

We've developed optimized approaches for:

Exotics: Inconel 718, Ti64, Hastelloy

Composites: CFRP, G10, ceramic-matrix

Plastics: PEEK, Ultem, PTFE

Hard metals: H13 (50+ HRC), tool steels

Request material-specific strategies in your quote.

Simple 3-step process:

1. Upload CAD at [secure portal link]

2. Receive quote + DFM feedback in 4 hours

3. Approve → Get G-code in 24h

No upfront payment - pay after code approval.