What is CNC Milling?

CNC Milling Services

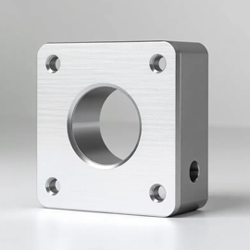

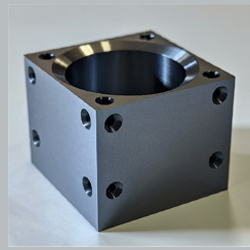

3 Axis CNC Milling

Online Quote3-axis milling operates along X, Y and Z linear paths, delivering cost-effective precision (±0.05 mm) for prismatic parts with planar features like pockets, slots and drilled holes. Ideal for aluminum, brass and engineering plastics (e.g., PEEK, acetal), it handles components up to 2,000 × 1,000 × 600 mm with optimized cycle times for prototypes and mid-volume runs. While limited to single-face machining, it excels at flatness-critical applications: baseplates, enclosures and mounting brackets requiring ±0.1 mm positional accuracy.

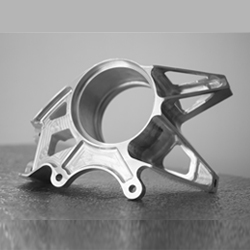

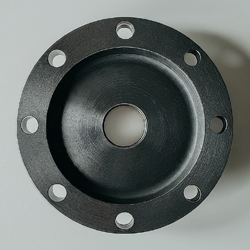

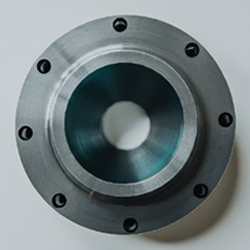

4-Axis CNC Milling

Online Quote4-axis milling integrates a rotary axis (A-axis) for indexed multi-face machining without re-fixturing, achieving ±0.05° angular accuracy on cylindrical or box-shaped parts. This enables complex features: radial holes, helical grooves and contoured profiles around a workpiece-ideal for gear housings, valve bodies and motor mounts in 316 stainless steel or 6061-T6 aluminum. With 60% faster production than 3-axis for rotational geometries, it maintains ±0.075 mm tolerances while eliminating cumulative setup errors common in marketplace supplier networks.

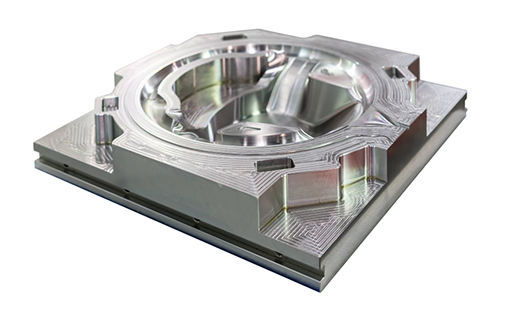

5-Axis CNC Milling

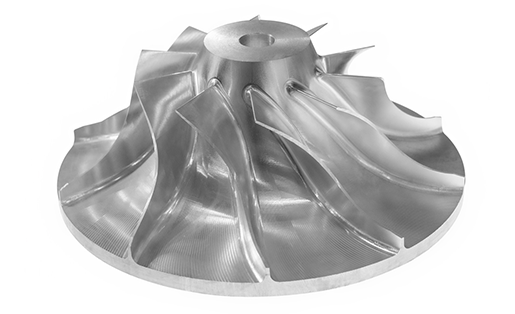

Online Quote5-axis simultaneous milling dynamically manipulates tools along five axes (X,Y,Z + B/C), enabling single-setup machining of organic contours, undercuts and compound angles at ±0.015 mm tolerances. High-speed spindles (24,000 RPM) sculpt aerospace titanium impellers, medical PEEK implants and injection mold cores with <0.8 μm surface finishes. Unlike competitors limited to 3+2 positioning, true 5-axis interpolation maintains optimal tool engagement for 70% faster material removal in hardened tool steels (HRC 50+) while achieving ±0.020 mm true position accuracy on aerospace bulkheads.

CNC Milling Tolerances

This reference defines achievable precision for 3-axis, 4-axis and 5-axis milling processes across linear dimensions, geometric profiles and surface finishes. Standard and tight tolerance ranges account for material behavior, part geometry and inspection methodologies to prevent manufacturing delays and non-conformance. Align designs with these process-specific benchmarks to balance functional requirements with cost efficiency across aerospace, medical and industrial applications.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | Critical Influencers |

|---|---|---|---|---|

| Linear Dimensions | ±0.125 mm (±0.005") |

±0.100 mm (±0.004") |

±0.075 mm (±0.003") |

Part size, fixturing stability |

| Hole Position (Ø<25 mm) | ±0.100 mm | ±0.050 mm | ±0.025 mm | Probe calibration, machine rigidity |

| Bore Diameter (H7) | ±0.50 mm | ±0.50 mm | ±0.50 mm | Tool deflection, cooling strategy |

| Flatness (100×100 mm) | 0.100 mm | 0.050 mm | 0.025 mm | Workholding, residual stresses |

| Angularity (Per 100 mm) | ±0.5° | ±0.1° | ±0.05° | Rotary axis precision |

| Surface Finish (Ra) | 3.2 μm (128 μin) |

3.2 μm (128 μin) |

3.2 μm (128 μin) |

Toolpath strategy, tool condition |

| True Position | 0.200 mm | 0.100 mm | 0.050 mm | Datum alignment, setup accuracy |

Tight/Achievable Tolerances

| Feature | 3-Axis | 4-Axis | 5-Axis |

|---|---|---|---|

| Linear Dimensions | ±0.050 mm | ±0.025 mm | ±0.010 mm |

| Hole Position (Ø<25 mm) | ±0.050 mm | ±0.020 mm | ±0.010 mm |

| Bore Diameter (H7) | ±0.050 | ±0.050 | ±0.050 |

| Flatness (100×100 mm) | 0.050 mm | 0.020 mm | 0.010 mm |

| Angularity (Per 100 mm) | ±0.2° | ±0.05° | ±0.05° |

CNC Milling Materials

|

Aluminum Aluminum CNC MachiningAluminum is a good choice for CNC milling due to its exceptional machinability, strength-to-weight ratio and versatility across industries like aerospace, automotive and electronics. Its softness allows for high-speed machining, reducing cycle times and tool wear, while maintaining precision for complex geometries and tight tolerances. Aluminum alloys, such as 6061 and 7075, offer excellent corrosion resistance, thermal conductivity and manufacturability, making them ideal for prototyping and high-volume production. Additionally, aluminum's compatibility with finishing processes like anodizing enhances durability and aesthetics. With recyclability and cost-effectiveness, aluminum ensures efficient, sustainable manufacturing solutions for functional parts and prototypes. About Aluminum Available Aluminum AlloysAluminum 6061-T6 Aluminum 6082 Aluminum 7075-T6 Aluminum 5083-H111 Aluminum 6063 Aluminum 5052 Aluminum 2024-T351 Aluminum 7050 Aluminum 2017A Aluminum 6082-T651 Aluminum 7075-T651 Aluminum 2014 Aluminum 6061-T651 Aluminum 7075-T7351 Aluminum 6082-T6 Aluminum 2014-T6 Aluminum 2024-T351 Aluminum 6063-T5 Aluminum 6063-T6 Aluminum 5083-H32 Aluminum 5052-H32 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Anodizing Electroless Nickel Plating Chromate Conversion Coating |

|

Copper Copper CNC MachiningCopper is an excellent material for CNC milling and prototyping, known for its unparalleled electrical and thermal conductivity, corrosion resistance. Its superior machinability allows for the precise fabrication of complex components with excellent surface finishes, making it a top choice for heat exchangers and custom industrial parts. While softer than some metals, copper's ductility enhances its manufacturability, enabling the production of designs with tight tolerances. Ideal for both functional prototypes and end-use parts in electronics, aerospace and energy sectors, copper offers reliable performance and is fully recyclable, supporting sustainable manufacturing practices. About Copper Available Copper AlloysCopper C101 Copper C110 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

Brass Brass CNC MachiningBrass is a highly versatile and machinable alloy ideal for CNC milling services, offering excellent manufacturability for both complex prototyping and high-volume production runs. Known for its superior machinability, brass allows for high-speed machining with exceptional surface finishes and minimal tool wear, reducing overall production time and cost. Its natural corrosion resistance and good electrical conductivity make it a preferred choice for manufacturing decorative fixtures, precision electrical components and durable industrial parts. Brass provides great value in custom manufacturing, ensuring reliable performance and ease of post-processing for various applications. About Brass Available Brass AlloysCopper C360 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating |

|

Bronze Bronze CNC MachiningBronze is a durable and versatile copper-based alloy, highly valued in CNC milling for its excellent wear resistance, low friction and exceptional corrosion resistance, especially in marine and industrial environments. Its good machinability allows for the precise manufacturing of complex components like bushings, bearings and architectural fittings. While slightly tougher to machine than brass, bronze offers superior strength and longevity, making it ideal for high-performance functional prototyping and end-use parts. The alloy's manufacturability supports the production of durable components that withstand heavy loads and harsh conditions, providing reliable solutions for industries from aerospace to artistic manufacturing. About Bronze Available Bronze Alloys932 Bearing Bronze 954 Bearing Bronze 544 Bearing Bronze As Machined Media Blasting Hand Polishing |

|

Tool Steel Tool Steel CNC MachiningTool Steel is engineered for extreme durability and performance, making it best choice for high-wear CNC milling applications in manufacturing and mold-making. While its hardness requires robust machining strategies, its exceptional strength, wear resistance and ability to hold a sharp edge are unmatched. This makes it ideal for producing long-lasting jigs, fixtures, cutting dies and industrial tooling. For prototyping functional tools or end-use production parts that must withstand high pressure and abrasion, tool steel offers superior performance. Its manufacturability is excellent for complex, high-precision components, ensuring reliability in the most demanding environments. About Tool Steel Available Tool Steel AlloysA2 Tool Steel D2 Tool Steel A3 Tool Steel O1 Tool Steel S7 Tool Steel H13 Tool Steel As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

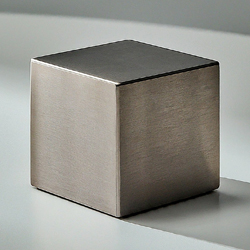

Stainless Steel Stainless Steel CNC MachiningStainless Steel is a cornerstone of precision CNC milling, offering an exceptional property of strength, corrosion resistance and versatility for both prototyping and high-volume manufacturing. Renowned for its durability in harsh environments, popular grades like 304 and 316 provide excellent manufacturability, allowing for the creation of complex, high-tolerance components with superior surface finishes. While its work-hardening nature requires specific machining expertise, its machinability is excellent with the right parameters, making it ideal for critical parts in the medical, aerospace, automotive and food processing industries. From heavy functional prototypes to end-use components, stainless steel ensures part longevity and reliable performance. About Stainless Steel Available Stainless SteelStainless Steel 304 Stainless Steel 316 Stainless Steel 303 Stainless Steel 416 Stainless Steel 2205 Stainless Steel 420 Stainless Steel 440C Stainless Steel 430 Stainless Steel 301 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide Electroless Nickel Plating Electropolishing |

|

Alloy Steel Alloy Steel CNC MachiningAlloy Steel is a high-strength material engineered for demanding CNC milling applications, offering superior hardness, toughness and wear resistance for critical components. Its excellent machinability allows for efficient manufacturing of complex gears, shafts and structural parts that withstand high stress and impact. While often requiring controlled machining parameters and heat treatment, alloy steel provides outstanding manufacturability for both functional prototyping and end-use production in automotive, aerospace and heavy machinery industries. This material ensures exceptional performance for parts that demand reliability under extreme conditions, making it a fundamental choice for robust manufacturing solutions. About Alloy Steel Available Alloy Steel AlloysAlloy Steel 4140 Alloy Steel 4340 Alloy Steel 1215 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

Mild Steel Mild Steel CNC MachiningMild Steel is a fundamental and cost-effective carbon steel offering excellent machinability for a wide range of CNC milling applications. Its low carbon content makes it soft and ductile, allowing for easy machining, welding and forming with minimal tool wear, which accelerates both prototyping and high-volume production. This versatility and superior manufacturability make it an ideal choice for manufacturing sturdy brackets, frames, fixtures and other structural components that require strength and reliability. While it lacks the corrosion resistance of stainless steel, mild steel is perfect for projects where cost-efficiency and straightforward fabrication are priorities, providing a dependable solution for functional parts across industrial and consumer sectors. About Mild Steel Available Mild Steel AlloysMild Steel 1018 Mild Steel 1045 Mild Steel A36 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide Electroless Nickel Plating |

|

Titanium Titanium CNC MachiningTitanium is the ultimate material for high-performance CNC milling, offering an exceptional strength-to-weight ratio, outstanding corrosion resistance and excellent biocompatibility. While its high strength presents machinability challenges requiring expert techniques and parameters, the result is unmatched for critical aerospace, medical implant and automotive components. Its superior performance under extreme temperatures and stress makes it ideal for functional prototyping and end-use manufacturing of parts. Despite its technical demands, titanium's manufacturability is excellent with advanced machining, providing lightweight, incredibly strong and durable solutions for the most demanding applications. About Titanium Available Titanium AlloysTitanium Grade 1 Titanium Grade 2 Titanium Grade 5 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

ABS ABS CNC MachiningABS is a premier engineering thermoplastic for CNC milling, renowned for its excellent impact strength, rigidity and superb machinability that enables fast, cost-effective prototyping and production. Its low melting point allows for high-speed machining with smooth surface finishes, making it ideal for creating durable concept models, functional prototypes and end-use parts like housings and fixtures. With good manufacturability and ease of post-processing-including sanding, painting and gluing-ABS is a versatile and economical choice for manufacturing across consumer goods, automotive and electronics industries, providing reliable performance and design flexibility. About ABS Available ABS FinishesAs Machined As Machined (medium) |

|

Acrylic Acrylic CNC MachiningAcrylic is an exceptional material for CNC milling, known for its clear optical clarity, high stiffness and excellent machinability that allows for the precise fabrication of complex prototypes and end-use parts. Its manufacturability is outstanding, enabling the production of components with smooth edges and fine details, making it ideal for manufacturing light pipes, lenses, signage and display components. While it can be brittle, its ability to be easily polished, bonded and finished results in a brilliant, glass-like appearance. Acrylic is a versatile and cost-effective solution for both rapid prototyping and production runs across industries like consumer products, medical and aerospace, offering durability and aesthetic qualities. About Acrylic Available Acrylic FinishesAs Machined As Machined (medium) |

|

Delrin Delrin CNC MachiningDelrin (Acetal) is a thermoplastic renowned for its exceptional machinability, low friction and high dimensional stability, making it the best choice for CNC milling precision components like gears, bushings and bearings. Its superior strength-to-weight ratio, moisture resistance and natural lubricity ensure reliable performance in prototyping and end-use manufacturing across automotive, aerospace and medical industries. With excellent creep resistance and ease of fabrication, Delrin enhances manufacturability for complex designs and tight tolerances, while its cost-effectiveness and compatibility with finishes like bead blasting support sustainable production workflows. About Delrin Available Delrin AlloysPOM-C POM-H As Machined As Machined (medium) |

|

HDPE HDPE CNC MachiningHDPE is a versatile and cost-effective thermoplastic ideal for CNC milling, offering excellent chemical resistance, low moisture absorption and high impact strength for both prototyping and end-use parts. Its superior machinability allows for smooth, efficient fabrication of lightweight components like cutting boards, fluid handling parts and packaging fixtures, with minimal tool wear. While softer than some other plastics, HDPE provides good manufacturability for complex geometries and is easily welded or fabricated post-machining. This material is a practical choice for manufacturing applications in food processing, chemical storage and consumer products, balancing durability with affordability for functional prototypes and production runs. About HDPE Available HDPE FinishesAs Machined As Machined (medium) |

|

Nylon Nylon CNC MachiningNylon is a high-performance thermoplastic ideal for CNC milling, offering exceptional strength, durability and excellent wear resistance for functional prototyping and end-use manufacturing. Known for its good machinability and toughness, it allows for the production of complex components like gears, bushings and structural parts that require low friction and high mechanical performance. With good chemical resistance and versatility, nylon provides reliable manufacturability across industries such as automotive, aerospace and consumer goods, making it a top choice for producing durable, lightweight and cost-effective components with consistent results. About Nylon Available Nylon AlloysNylon 6/6 Nylon 6 (30% Glass Filled) As Machined As Machined (medium) |

|

Polycarbonate Polycarbonate CNC MachiningPolycarbonate is a thermoplastic renowned for its exceptional impact strength, optical clarity and thermal resistance, making it the best choice for CNC milling durable prototypes and end-use parts. With good machinability, it allows for precise fabrication of complex components like protective covers, lenses and structural housings, though it requires specific tooling to prevent melting or stress cracking. Its excellent manufacturability supports tight tolerances and smooth finishes, ideal for prototyping and production across automotive, medical and electronics industries. Polycarbonate's versatility, combined with its ability to be polished, painted or coated, ensures high-performance results in functional manufacturing applications demanding transparency and durability. About Polycarbonate Available Polycarbonate FinishesAs Machined As Machined (medium) |

|

As Machined StandardThe As Machined Standard finish offers the fastest turnaround and lowest cost, providing clean, functional parts with tight tolerances directly from our CNC milling machines, with no secondary finish. Learn more Finish Specifications

|

|

As Machined MediumOur As Machined Medium finish provides a smoother surface with reduced tool marks at a cost-effective price, ideal for functional prototypes and semi-cosmetic parts. This optimized CNC milling process offers an excellent balance of improved surface quality and quick turnaround. Learn more Finish Specifications

|

|

As Machined FineAchieve the smoothest possible surface straight from the machine with our As Machined Fine finish. This precision CNC milling process delivers minimal tool marks and the lowest surface roughness (Ra) without secondary processing, ideal for high-end prototypes and precision components. Learn more Finish Specifications

|

|

Bead BlastingOur Bead Blasting finish delivers a uniform, satin-smooth matte texture, ideal for minimizing surface imperfections and enhancing overall finish quality, non-reflective aesthetic. This process is also perfect for preparing surfaces for secondary operations like anodizing. Learn more Finish Specifications

|

|

BrushedCreate a uniform texture with our Brushed finish. This aesthetic surface treatment provides a modern, non-reflective look that effectively hides fingerprints and minor scratches, making it the best choice for consumer products and decorative panels. Learn more Finish Specifications

|

|

Chromate Conversion CoatingProvide exceptional corrosion resistance and a distinctive iridescent appearance with our Chromate Conversion Coating finish. This chemical process passivates aluminum and zinc parts, offering excellent protection and improved paint adhesion for components in aerospace, military and automotive applications. Learn more Finish Specifications

|

|

PolishingAchieve a mirror-like, highly reflective surface with our professional polishing service. This finishing process enhances both aesthetic appeal and corrosion resistance, ideal for consumer products and high-end applications. Learn more Finish Specifications

|

|

Powder CoatingDeliver exceptional durability and a wide range of color options with our professional powder coating service. This tough, wear-resistant finish provides superior protection against corrosion, chipping and scratches, making it ideal for both consumer products and industrial equipment. Learn more Finish Specifications

|

|

Black OxideOur Black Oxide finish provides a durable matte black surface that offers mild corrosion resistance and minimal dimensional change. This conversion coating is ideal for tools, firearms and automotive components seeking a sleek, non-reflective appearance. Learn more Finish Specifications

|

|

Electroless PlatingOur Electroless Plating finish delivers a uniform, hard nickel-phosphorus coating on CNC machined parts, even on complex geometries. This process provides excellent corrosion and wear resistance without electricity, making it ideal for high-precision components in aerospace, automotive and hydraulic systems. Learn more Finish Specifications

|

|

Anodizing Type 2Our Anodizing Type 2 finish creates a durable, corrosion-resistant aluminum oxide layer through an electrolytic passivation process. This decorative anodizing offers excellent wear resistance and is available in a wide spectrum of colors for both protection and an aesthetic on CNC machined aluminum parts, ideal for consumer goods and medical devices. Learn more Finish Specifications

|

|

Anodizing Type 3 (Hard)Our Anodizing Type 3 (Hard) finish, also known as hard coat anodizing, creates an extremely thick, dense and wear-resistant surface. This electrolytic process offers superior corrosion protection, high dielectric strength and low friction for demanding industrial, aerospace, military and automotive applications. Learn more Finish Specifications

|

CNC Milling Design Guidelines

Follow these critical parameters to ensure manufacturability across 3-axis, 4-axis and 5-axis milling operations. This table defines essential thresholds for wall thickness, feature complexity and geometric constraints - preventing costly redesigns, tooling failures and tolerance violations. By aligning designs with process-specific capabilities, you optimize part functionality while controlling production costs and lead times.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling |

|---|---|---|---|

| Wall Thickness | 1.0 mm (metals) 1.5 mm (plastics) |

1.0 mm (metals) 1.2 mm (plastics) |

0.8 mm (metals) 1.0 mm (plastics) |

| Hole Depth | ≤4× diameter | ≤5× diameter | ≤6× diameter |

| Internal Corners | R0.5 mm+ | R0.4 mm+ | R0.3 mm+ |

| Undercuts | Not possible | Limited (axis-parallel) | Full capability (any angle) |

| Tolerances | ±0.125 mm (std) ±0.050 mm (tight) |

±0.100 mm (std) ±0.025 mm (tight) |

±0.050 mm (std) ±0.020 mm (tight) |

| Text Engraving | Top faces only | 3+ faces with indexing | Any surface |

| Max Cavity Depth | ≤3× width | ≤4× width | ≤5× width |

| Surface Finish (Ra) | 3.2 μm (std) 0.4 μm (opt) |

3.2 μm (std) 0.4 μm (opt) |

3.2 μm (std) 0.4 μm (opt) |

| Critical Tips | Avoid side features Chamfer all edges |

Align features with rotation axis Allow tool clearance |

Minimize tool length Leverage compound angles |

Clarwe's Quality & Certifications Guarantee

All parts are validated in-house: Clarwe's Guarantee of Zero-Defect Parts

Every component is sourced from our vetted ISO/AS-certified manufacturing partners, then 100% physically inspected at our facility before shipment. Unlike others, we enforce a 3-stage custody protocol:

| Material Compliance: | We order and validate material certifications (RoHS, REACH, mill test reports) on your behalf. |

| In-House Verification: |

Dimensional accuracy checks via CMM, VMM, 2D height gauges and precision tools. Critical feature validation against your drawings (hole positions, thread fits, flatness). Visual inspection for surface defects, burrs and cosmetic flaws. |

| Final Certification: | Full documentation including material certs, CoCs and inspection logs. |

| We guarantee: | ±0.020 mm tolerances on all

shipped parts (validated in-house). Zero paperwork gaps - we manage all supplier certifications. 100% physical custody - no direct supplier shipments delivering zero-defect compliance from prototype to 100,000+ part production runs. |

Why Choose Clarwe for Precision CNC Milling Services?

Our integrated ecosystem can deliver complex 3-axis, 4-axis or 5-axis machined parts delivered fast and accurately. Clarwe combine enterprise-grade capabilities, from high-speed aluminum milling to titanium aerospace components. Leverage our network of 200+ ISO 9001/AS9100-certified manufacturers to seamlessly scale from 1 prototype to 50,000+ production parts, all held to tolerances as tight as ±0.020 mm and backed by full material certifications. We ensure consistency through rigorous quality controls: every part undergoes in-house inspection and comes with a downloadable Certificate of Conformity.

Manage everything effortlessly through our intuitive dashboard: track orders in real time, approve revisions online, download inspection reports and coordinate shipments - all in one place. No more chasing emails or navigating clunky portals. We guarantee on-time delivery (99.6% success rate) and zero cost surprises, with a 100% quality promise: if we miss a spec, we'll remake your parts at our cost and expedite shipping. Upload your CAD file for Online Quote backed by our risk-free commitment.

Clarwe's Platform Advantage

Our integrated dashboard delivers end-to-end project command, streamlining workflows while ensuring transparency at every stage. Experience seamless coordination from initial request to final delivery, all within a single secure interface.

Submit & Configure

| RFQ Initiation |

Upload CAD files (STEP, IGES, SLDPRT) and drawings Specify requirements: materials, tolerances, finishes, inspection protocols Request custom documentation: material certs, CMM reports, customs forms |

| Real-Time Quoting |

Receive online DFM analysis with cost drivers flagged Adjust configurations (e.g., material substitutions) to optimize pricing |

Order Execution & Oversight

| Document Management |

Submit customs declarations, commercial invoices and HS codes Upload purchase orders or approve terms for payment Access digital invoices with tax/line-item breakdowns |

| Production Intelligence |

Track progress and updates View Shop floor photos/videos Access Inspection reports, quality documents and Material certifications Monitor shipping status with carrier integrations |

Proactive Collaboration & Support

| Engineer Engagement |

Send technical queries and status enquiries to our engineers via encrypted chat Receive resolution timelines for technical queries |

| Quality Assurance Hub |

Access pre-shipment documentation: First-article inspection reports, dimensional reports and quality

documents Approve/reject deliverables via annotated media |

| Post-Delivery Excellence |

Initiate reorders with one-click cloning Log support tickets for non-conformances Archive project history (drawings, certs, comms) for audits |

Industries specialized

Aerospace

Automotive

Consumer Products

Medical

Ready to get started?

Frequently Asked Questions about CNC Milling

We guarantee standard tolerances per AS9001, ISO 2768 and ±0.010 mm tight tolerances on 5-axis machines for flight-critical or implant components, validated by in-house CMMs. All parts come with full material traceability and industry-standard inspection reports.

| Process | Best For | Lead Time | Cost Premium |

|---|---|---|---|

| 3-Axis | Prismatic parts | 1-5 days | Baseline |

| 4-Axis | Cylindrical features | +1 day | +15-25% |

| 5-Axis | Organic contours | +2 days | +30-50% |

Design: Avoid ±0.025 mm tolerances on non-critical features (35% savings)

Material: Use 6061 vs. 7075 aluminum (30% savings)

Process: Nest multiple parts in 3-axis (>40% material utilization)

Message your project engineer via dashboard for real-time adjustments.

Changes pre-machining are free;

post-machining incur costs only with signed approval.

3-axis is ideal for prismatic parts with features on one face (e.g., plates, brackets). It's the most

cost-effective for simpler geometries.

4-axis adds a rotary axis, allowing machining on multiple sides of a part in a single setup (e.g., camshafts,

custom gears), reducing fixturing time and errors.

5-axis simultaneous machining allows the tool to move dynamically along five axes at once. It's essential for

complex organic contours like turbine blades, impellers and aerospace components with tight tolerances (±0.025

mm), as it eliminates multiple setups and drastically improves accuracy.

We machine a vast range of materials. For:

High Strength-to-Weight Ratio: Aluminum 7075-T6 or Titanium Grade 5 are aerospace standards.

High-Temperature Resistance: Inconel 718 (superalloy), PEEK (engineered plastic) or Titanium.

Wear Resistance: Tool Steels (e.g., A2, D2) or Stainless 304/316.

General Purpose: Aluminum 6061-T6 or Acetal (POM). We provide full material certifications and will advise on

the best choice during the DFM process.

Our standard milling tolerance is ±0.125 mm.

We can reliably hold ±0.025 mm for critical features on most parts.

For 5-axis machining of stable materials, we can achieve ±0.020 mm.

All tight tolerances are verified with in-house CMM inspection, a service we include at no extra cost, unlike

many marketplace competitors.

Quality is engineered into our process, not inspected in later. We perform 100% in-house validation at our

facility. This includes:

First-Article Inspection: CMM verification against your GD&T.

In-Process Checks: Live toolpath monitoring and probing.

Surface Finish Validation: Measured with profilometers.

This hands-on approach prevents the quality lottery of broker platforms that rely on supplier self-reporting.

It can be, but it's a challenge we specialize in solving.

Our high-speed machining (HSM) capabilities and trochoidal milling strategies are designed for efficient

material removal in deep pockets while minimizing stress and heat.

For thin walls, we optimize toolpaths, tools and feeds/speeds to prevent chatter and deflection.

We will provide specific DFM feedback on minimum recommended wall thicknesses during quoting.

Yes. Our network includes large-format gantry mills capable of handling parts up to 2,000 x 1,000 x 600 mm (78"

x 39" x 24").

For larger components, we can coordinate a segmented machining strategy and provide assembly services.

Absolutely. We offer a complete range of post-processing to meet aesthetic and functional requirements:

Anodizing (Type II & III / Hardcoat)

Powder Coating

Bead Blasting & Media Finishing

Passivation (for stainless steel)

Precision Polishing to mirror finishes (Ra < 0.4 μm)

For the most accurate quote and DFM analysis, please upload a 3D CAD file (STEP, IGES, SLDPRT, X_T preferred)

along with a 2D PDF drawing with critical dimensions, tolerances and GD&T callouts.

This allows our engineers to fully understand your design intent.

Our connected manufacturing network allows for highly competitive lead times:

Prototypes: 1-3 days for standard materials.

Production Runs: 5-10 business days.

We consistently outperform marketplace brokers because we control the quality process internally, eliminating

the delays that come from coordinating and validating multiple external shops.