Hand polishing is a manual finishing process used to refine and enhance surfaces by removing imperfections, oxidation or scratches. It involves applying apolishing compound with a cloth, pad or brush and using controlled pressure to achieve the desired smoothness and shine. This technique is widely used onmetals , wood,plastics and stones to restore luster, improve aesthetics and prepare surfaces for further treatment. Hand polishing offers precision, allowing careful control over delicate or intricate parts. While it requires more time and effort than mechanical polishing, it ensures a high-quality finish, making it ideal for fine detailing and restoration work.

All metals like (Aluminum ,stainless steel etc.) and some plastics.

Achieves Ra ≤ 0.2 µm.

High gloss, reflective finish.

Suitable for Class A surfaces.

≤ 5 µm material removal.

Smooth, isotropic surface pattern.

6061 T6, 6082, 7075-T6, 5083-H111, 6063, 5052, 2024-T351, 7050, 2017A, 6082-T651, 7075-T651, 2014, 6061-T651, 7075-T7351, 6082-T6, 2014-T6, 6063-T5, 6063-T6, 5083-H32, 5052-H32

A2 Tool steel, D2 Tool steel, A3 Tool Steel, O1 Tool Steel, S7 Tool Steel, H13 Tool Steel

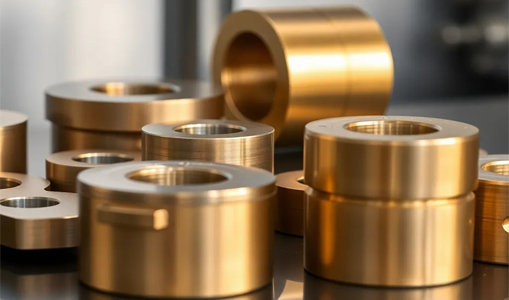

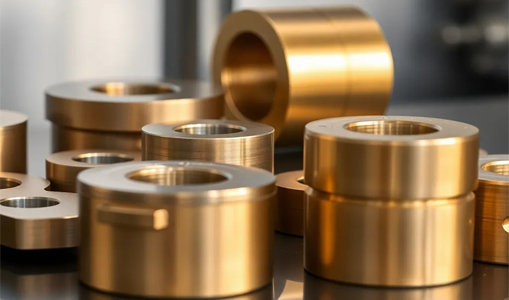

932 Bearing Bronze , 954 Bearing Bronze, 544 Bearing Bronze

Tools typically include abrasive papers or pads, buffing wheels and polishing compounds. The selection of tools depends on the material and desired finish.

Benefits include achieving a high-gloss finish, improving surface smoothness, enhancing corrosion resistance and increasing the part's overall aesthetic appeal.

Hand polishing can significantly reduce surface roughness by removing microscopic peaks and valleys, resulting in a smoother and more reflective surface.