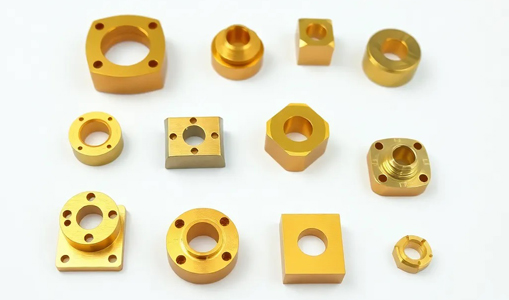

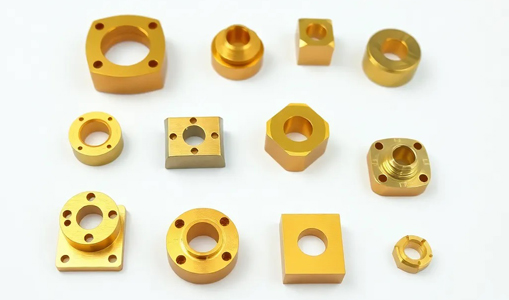

Electroless plating is an autocatalytic chemical process that deposits a uniform metal coating onto a substrate without the use of external electrical current. This surface treatment typically uses nickel-phosphorus or nickel-boron alloys, offering excellent corrosion resistance, wear resistance and uniform thickness, even on complex geometries and internal features. Unlike electroplating, electroless plating provides consistent coverage regardless of part shape, making it ideal for components with complex cavities or sharp edges. The coating thickness typically ranges from 0.0001 to 0.005 inches (2.5 to 125 µm) and the resulting surface roughness can vary from 0.2 to 1.0 µm Ra, depending on substrate condition and bath composition. Electroless nickel plating also enhances surface hardness, reaching up to 1000 HV with heat treatment, which is beneficial in high-wear applications. The process maintains dimensional precision, crucial for tight-tolerance parts. It is widely used in industries such asaerospace,automotive, electronics and oil & gas. Electroless plating can also improve solderability and electrical conductivity, making it suitable for both mechanical and electronic components.

All metals like (Aluminum,stainless steel etc.) and plastics.

Typically Ra 0.05–0.2 µm.

Bright to matte metallic finish.

Glossy, satin or dull (based on phosphorus level).

3μm to 40μm , controllable.

Follows substrate; fine to amorphous.

A2 Tool steel, D2 Tool steel, A3 Tool Steel, O1 Tool Steel, S7 Tool Steel, H13 Tool Steel

Typical coatings range from 5 to 50 microns, but specialized applications can achieve up to 100 microns with careful bath control.

High phosphorus (>10%): Superior corrosion resistance, non-magnetic, lower hardness.Medium phosphorus (6-9%): Balanced hardness, corrosion resistance and moderate brightness.Low phosphorus (<5%): High hardness, excellent wear resistance, but lower corrosion protection.

Regular monitoring of pH, nickel ion concentration and reducing agent levels is essential. Filtration and replenishment help maintain bath stability and prevent contamination.