| Rapid prototyping is a product development methodology that quickly transforms design concepts into physical parts for functional testing and validation. By creating physical models from CAD data, this process enables engineers to verify form, fit and function early in the development cycle, significantly reducing both time-to-market and development costs. | Unlike traditional manufacturing methods that require expensive tooling and long setup times, rapid prototyping utilizes advanced manufacturing technologies to produce parts in as little as 1 to 3 business days. This accelerated approach allows for iterative design improvements, ensuring potential issues are identified and resolved before committing to mass production. | At Clarwe, we go beyond basic prototyping by combining latest technology with expert engineering guidance. Our approach ensures your prototypes not only look like the final product but also perform to specification, providing invaluable data for making critical design decisions with confidence. |

Identify design flaws early when changes are least expensive to implement

Avoid costly tooling modifications and production delays

Compress development cycles from months to weeks

Create physical models for investor presentations and team consensus

Gather authentic user experiences before final production

At Clarwe Manufacturing, we provide end-to-end rapid prototyping solutions that bridge the gap between concept and production. Our engineer-assisted approach ensures each prototype delivers maximum value through expert process selection, design optimization and rigorous quality control.

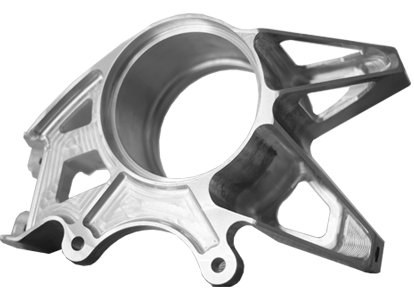

Create production-grade prototypes with exact material properties and tolerances down to ±0.020 mm.

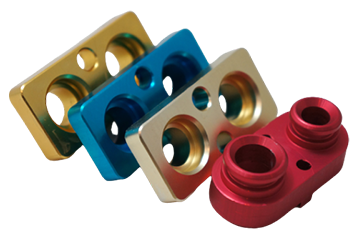

Multi-axis CNC milling and turning capabilities can handle complex geometries in over 50+ metal and

plastic

materials.

• 3-4-5 Axis Milling & Turning Centers

• ±0.020 mm Tight Tolerances

• 50+ Engineering-Grade Materials

• Free design-for-manufacturability (DFM) analysis on Every Quote

• First Article Inspection with CMM Reports

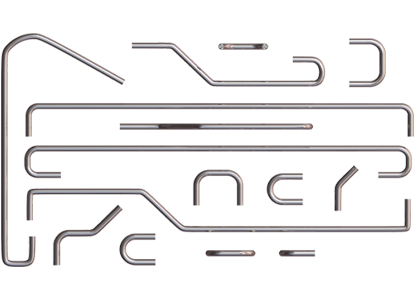

Prototype precision tubular components with consistent wall thickness and minimal deformation. CNC

tube bending technology creates complex shapes for aerospace, automotive and medical applications.

• 3D Bent Tube Prototypes with CAD-to-Part Accuracy

• Materials: Mild Steel, Stainless Steel, Aluminum, Copper and more

• Mandrel Bending for Critical Applications

• Complete End-Finishing and Fabrication

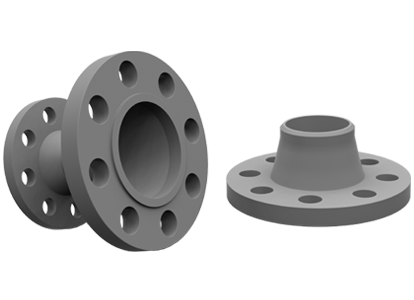

Produce high-quality prototypes that mimic production parts in appearance and performance. Create

10-500+ parts from a single master pattern with turnaround in 3 to 5 days.

• 120+ Urethane Materials Simulating Production Plastics

• Class A Surface Finishes and Textures

• Overmolding and Insert Capabilities

• Cost-Effective for Small Batch Runs

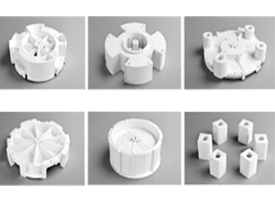

Create true production-grade parts using aluminum mold tooling for functional testing and market

validation. Ideal for runs of 50-10,000+ parts.

• Aluminum Mold Tooling with Rapid Turnaround

• Production-Grade Thermoplastic Materials

• Full DFM for Production Optimization

• Seamless Transition to Mass Production

Produce precision gear prototypes with exact tooth profiles, pitch diameters and surface finishes for

accurate performance testing.

• Spur, Helical, Bevel and Worm Gears

• Precision Grinding for Critical Applications

• Backlash Control and Noise Optimization

• Material Selection for Wear and Durability

Create functional sheet metal prototypes using the same processes as production manufacturing, including

laser cutting, punching, bending and welding.

• Laser Cutting with ±0.1 mm Tolerance

• CNC Punching and Forming

• Welding and Assembly Services

• Surface Finishing and Coating Options

| Technology | Lead Time | Tolerances | Applications | Quantity |

|---|---|---|---|---|

| CNC Machining | 1 to 3 days | ±0.020 mm | Functional testing, precision parts | 1-500+ |

| CNC Tube Bending | 2 to 4 days | ±0.1 mm | Fluid systems, structural tubes | 1-120+ |

| Urethane Casting | 3 to 5 days | ±0.125 mm | Appearance models, consumer products | 50-10,000+ |

| Rapid Injection Molding | 5 to 15 days | ±0.025 mm | Production-grade validation | 50-10,000+ |

| Gear Manufacturing | 3 to 6 days | ±0.025 mm | Mechanical systems, drive trains | 1-250+ |

| Sheet Metal Fabrication | 2 to 4 days | ±0.1 mm | Enclosures, brackets, frames | 1-1000+ |

While some platforms have replaced experts with automation, we've done the opposite. At Clarwe, we put our engineers-and their deep understanding-at the heart of every project. Because we believe true precision comes from human ingenuity. Discover the difference our people-first approach makes.

Every design receives engineer review with free design-for-manufacturability (DFM) feedback. Our experts identify potential issues and suggest improvements before manufacturing begins.

Simplify your supply chain. We own your project from start to finish, leveraging our extensive vetted network of 520+ manufacturing partners.

Rigorous in-house quality control with free First Article Inspection Reports (FAIR) and CMM verification included with every order.

Direct communication with our manufacturing engineer and real-time production tracking through our customer portal.

95% on-time delivery rate with expedited options available. Most CNC prototypes ship in 3 to 5 days.

Engineer-Assisted with Free DFM

±0.020 mm

Free FAIR & CMM Reports

520+ Vetted Partners

3 to 5 Days (Guaranteed)

Free DFM & Consultation

Direct to Engineer

All-Inclusive Pricing

At Clarwe Manufacturing, we've streamlined the rapid prototyping process to be as efficient and transparent as possible. Unlike automated platforms, you'll work with real engineers at every step to ensure your project's success.

| Upload & Receive Expert Quote | Review & Approve with Confidence | Production & Quality Assurance | |

|---|---|---|---|

| What You Do | Upload your 3D CAD files (STEP, IGES, SLDPRT) and requirements through our secure portal. | Review your quote and DFM suggestions. Discuss options directly with our engineer. | Monitor real-time production updates through our portal while we handle everything. |

| What We Do | Engineer Review: A dedicated manufacturing expert analyzes your design. | Direct Engineer Access: Speak directly with our manufacturing expert. | Expert Manufacturing: Your parts are produced by specialized partners. |

| Free design-for-manufacturability (DFM) Analysis: We identify potential issues and optimization opportunities. | Design Optimization: Implement improvements based on our recommendations. | In-House Quality Control: We perform rigorous inspections using CMM and advanced metrology. | |

| Process Recommendation: We suggest the ideal manufacturing process for your project. | Production Planning: Finalize timelines and confirm specifications. | Comprehensive Documentation: Includes free First Article Inspection Reports (FAIR). | |

| Fast

Shipping: Carefully packaged and shipped with tracking updates. Complete transparency with professional quality validation included. |

Order

Approval: Provide formal confirmation before manufacturing begins. Human collaboration ensures your design is perfected before production. |

Fast

Shipping: Carefully packaged and shipped with tracking updates. Complete transparency with professional quality validation included. |

Clarwe partners with engineers and product developers who require more than just parts - they require certainty, precision and expertise. Our rigorous quality standards, material traceability and engineering support make us the preferred rapid prototyping partner for industries where failure is not an option.

| Industry | Common Applications | How Clarwe Excels |

|---|---|---|

|

Aerospace & Defense Explore Aerospace Prototyping |

Flight-critical

components

and assemblies Aerospace and drone parts Satellite and spacecraft mechanisms Ground support equipment Avionics enclosures and mounts |

Material certifications

and

full traceability AS9100-compliant quality processes Extreme environment material expertise ISO-compliant manufacturing options First Article Inspection to AS9102 standards |

|

Medical & Life Sciences Explore Medical Device Prototyping |

Surgical instruments

and

prototypes Diagnostic equipment components Implantable device prototypes Medical device housings and enclosures Laboratory equipment and fixtures |

ISO 13485 compliant

processes Biocompatible material expertise Cleanroom manufacturing capabilities Micro-precision machining to ±0.005 mm Documentation for regulatory submissions |

|

Automotive & Transportation Explore Automotive Quote |

Engine and

transmission

components EV battery enclosures and thermal systems Sensors and mounting brackets Interior components and prototypes Custom automotive restoration parts |

Production-grade

materials

for testing High-volume transition capability PPAP documentation support Material testing and validation Custom finishing and coating options |

|

Industrial Equipment & Robotics Explore Industrial Prototyping |

Robotic arms and end

effectors Custom gears and drive systems Machinery components and housings Conveyor system parts Heavy equipment prototypes |

High-strength material

expertise Wear-resistant surface treatments Large-part machining capability Precision gear manufacturing Structural validation support |

|

Consumer Electronics & Products Explore Consumer Products Prototyping |

Product enclosures and

housings Heat management systems Connectors and internal components Wearable technology prototypes Product validation units |

Aesthetic finishing

expertise EMI/RFI shielding solutions Overmolding and multi-material parts Rapid iteration capability User experience validation support |

Our engineers understand your industry's unique requirements and help optimize designs for specific operational environments and regulatory standards.

We provide the documentation and certifications your industry requires, from material certifications to first article inspection reports.

Your designs are safe with us. We maintain strict confidentiality protocols and secure manufacturing processes.

We seamlessly integrate with your existing supply chain, providing prototypes that transition smoothly to production.

80+ Aerospace & Medical-Grade Metals/Plastics

Source rigorously documented materials through our vetted supplier network.

We guarantee full traceability with mill test reports and compliance certifications for

aerospace, automotive, medical and industrial applications.

30+ Surface Solutions for Aerospace & Medical Components

Ensure regulatory compliance and enhanced performance with our vetted

finishing partners. All processes include full documentation – from MIL-SPEC

anodizing to FDA-compliant coatings – backed by material certifications and batch traceability.

Yes, every quote includes free design-for-manufacturability (DFM) analysis from our manufacturing engineers. We identify potential issues and suggest optimizations for cost, performance and manufacturability before you place your order.