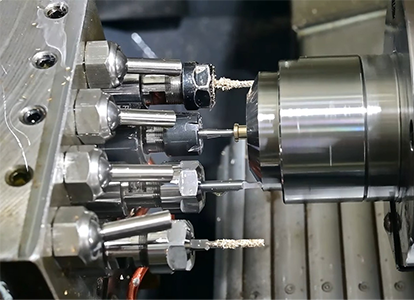

What is CNC Turning?

Precision CNC Turning Services

Delivering ±0.015 mm tolerance cylindrical parts via CNC lathes and Swiss machines for shafts, fittings and connectors in aerospace titanium, medical PEEK and automotive alloys. Our Ø500 mm × 4,500 mm capacity, live tooling for mill-turn operations and 100% in-house inspection ensure AS9100D/ISO 13485-compliant components with 30% faster lead times and included material certifications, outperforming marketplace brokers in precision, quality control and cost efficiency for prototypes through high-volume production.

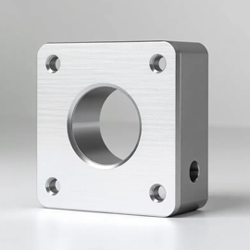

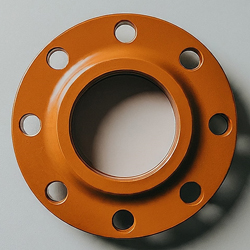

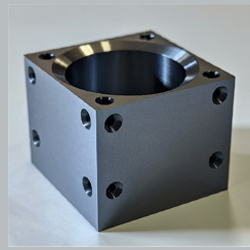

Standard Turning

Online QuotePrecision high-volume production for cylindrical shafts, fittings and connectors via automated lathes with Ø500 mm × 4,500 mm capacity and ±0.025 mm tolerances. Ideal for aluminum, stainless steel, brass and acetal, this process delivers cost-effective runs of 10k+ parts with 2x faster cycle times than marketplace alternatives featuring automatic bar feeders, live tooling for cross-drilling and CMM-validated concentricity (ISO 2768-compliant) for automotive, industrial and consumer electronics applications.

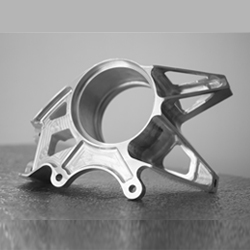

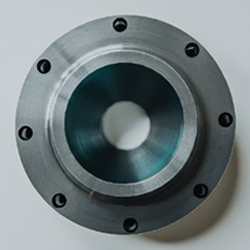

Mill-Turn

Online QuoteSingle-setup complex machining integrating rotational turning with milling, drilling and threading via 11-axis CNC mill-turn centers. Achieve ±0.015 mm positional accuracy on features like flanges, off-axis ports and contoured profiles in titanium, Inconel® or PEEK eliminating refixturing errors and slashing lead times by 40% vs. competitors workflows. Essential for aerospace actuators, medical device housings and defense components requiring full GD&T compliance and controlled documentation.

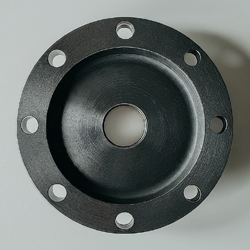

Swiss Machining

Online QuoteMicro-precision turning for long, slender components (L:D ≤ 20:1) with ±0.015 mm tolerances and 0.4 μm Ra finishes using guide bushings and subspindles. Specialized in medical implants (bone screws, surgical pins) and electronics connectors (contact sleeves, terminals) from 0.5-32 mm diameters in stainless 316L, titanium Gr23 or Nitinol, guaranteeing zero deflection even at 0.2 mm wall thicknesses. Includes real-time statistical process control (SPC) reports, surpassing competitor's capabilities for miniature, high-tolerance applications.

CNC Turning Tolerances

This reference establishes precision benchmarks for standard turning, Swiss machining and mill-turn operations across critical dimensions like diameters, concentricity and surface finishes. Process-specific tolerance ranges account for material behavior, L/D ratios and inspection methodologies to prevent manufacturing non-conformance while balancing functional requirements with cost efficiency. Align your designs with these industry-proven parameters to ensure reliable performance of shafts, connectors and rotational components in medical, aerospace and automotive applications.

| Feature | Standard Turning | Swiss Machining | Mill-Turn |

|---|---|---|---|

| Diameter (Ø<50mm) | ±0.025 mm | ±0.015 mm | ±0.015 mm |

| Length | ±0.050 mm | ±0.020 mm | ±0.030 mm |

| Concentricity | 0.050 mm | 0.010 mm | 0.020 mm |

| Thread Pitch (M6-M24) | ±0.15 mm | ±0.10 mm | ±0.10 mm |

| Surface Finish (Ra) | 1.6 μm (64 μin) | 1.6 μm (64 μin) | 1.6 μm (64 μin) |

| True Position | 0.100 mm | 0.030 mm | 0.050 mm |

| Flatness | 0.100 mm | 0.050 mm | 0.075 mm |

Tight/Achievable Tolerances

| Feature | Standard Turning | Swiss Machining | Mill-Turn |

|---|---|---|---|

| Diameter (Ø<50mm) | ±0.015 mm | ±0.010 mm | ±0.010 mm |

| Concentricity | 0.020 mm | 0.005 mm | 0.010 mm |

| Thread Pitch | ±0.10 mm | ±0.10 mm | ±0.10 mm |

| Surface Finish (Ra) | 0.2 μm (8 μin) | 0.2 μm (8 μin) | 0.2 μm (8 μin) |

| True Position | 0.050 mm | 0.015 mm | 0.025 mm |

CNC Turning Materials

|

Aluminum Aluminum CNC MachiningAluminum is a widely utilized material in CNC turning, valued for its excellent machinability and favorable strength-to-weight ratio. Its inherent properties make it a top choice for both rapid prototyping and high-volume production runs. The material's manufacturability allows for high-speed machining, complex geometries and the creation of parts with superior dimensional stability and smooth surface finishes. About Aluminum Available Aluminum AlloysAluminum 6061-T6 Aluminum 6082 Aluminum 7075-T6 Aluminum 5083-H111 Aluminum 6063 Aluminum 5052 Aluminum 2024-T351 Aluminum 7050 Aluminum 2017A Aluminum 6082-T651 Aluminum 7075-T651 Aluminum 2014 Aluminum 6061-T651 Aluminum 7075-T7351 Aluminum 6082-T6 Aluminum 2014-T6 Aluminum 2024-T351 Aluminum 6063-T5 Aluminum 6063-T6 Aluminum 5083-H32 Aluminum 5052-H32 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Anodizing Electroless Nickel Plating Chromate Conversion Coating |

|

Copper Copper CNC MachiningCopper is a highly ductile material commonly selected for CNC turning projects where superior electrical and thermal conductivity are critical. Its excellent machinability allows for the precise manufacturing of complex components, though its soft nature requires specific tooling considerations to prevent galling and achieve desired surface finishes. This combination of properties makes copper essential for prototyping and production of electrical connectors, heat exchangers and various industrial components. About Copper Available Copper AlloysCopper C101 Copper C110 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

Brass Brass CNC MachiningBrass is a free-machining copper alloy favored in CNC turning for its excellent machinability, corrosion resistance and good electrical conductivity. Its relatively low melting point and soft nature enable high-speed machining, resulting in faster production times and superior surface finishes. These properties make brass a versatile material for manufacturing precision components like fittings, valves, electrical connectors and low-friction decorative parts. About Brass Available Brass AlloysCopper C360 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating |

|

Bronze Bronze CNC MachiningBronze is a copper-based alloy, primarily with tin, valued in CNC turning for its excellent machinability, good corrosion resistance and low friction properties . Its versatility allows for efficient prototyping and high-volume production of components like bearings, bushings and electrical connectors . The material's manufacturability is enhanced by its ability to achieve tight tolerances and smooth surface finishes, though optimal results depend on selecting the appropriate bronze grade (e.g., phosphor bronze for elasticity or aluminum bronze for strength) and employing suitable cutting parameters. Bronze's inherent durability and wear resistance make it a reliable choice for parts subjected to continuous frictional contact or harsh environments. About Bronze Available Bronze Alloys932 Bearing Bronze 954 Bearing Bronze 544 Bearing Bronze As Machined Media Blasting Hand Polishing |

|

Tool Steel Tool Steel CNC MachiningTool Steel is a high-carbon alloy engineered for exceptional hardness, wear resistance and durability, making it a demanding yet viable material for CNC turning applications. Its machinability varies significantly by grade, often requiring specialized tooling, precise speeds and feeds to achieve desired results without compromising tool life. The manufacturability of tool steel is critical in producing robust molds, dies, cutting tools and high-wear components, where its ability to hold extreme tolerances and complex geometries is essential. While challenging to machine, its performance in prototyping and end-use manufacturing ensures reliability for parts subjected to intense mechanical stress and abrasive conditions. About Tool Steel Available Tool Steel AlloysA2 Tool Steel D2 Tool Steel A3 Tool Steel O1 Tool Steel S7 Tool Steel H13 Tool Steel As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

Stainless Steel Stainless Steel CNC MachiningStainless Steel is a corrosion-resistant iron alloy valued in CNC turning for its strength, durability and resistance to extreme environments. While its machinability varies by specific grade (e.g., 303 offers improved machinability over 304), achieving optimal results requires precise tooling and parameters to manage work hardening. This manufacturability makes it a fundamental material for producing high-performance components in medical, aerospace, food processing and marine applications, where precision parts must maintain structural integrity and resist corrosion throughout their lifecycle. About Stainless Steel Available Stainless SteelStainless Steel 304 Stainless Steel 316 Stainless Steel 303 Stainless Steel 416 Stainless Steel 2205 Stainless Steel 420 Stainless Steel 440C Stainless Steel 430 Stainless Steel 301 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide Electroless Nickel Plating Electropolishing |

|

Alloy Steel Alloy Steel CNC MachiningAlloy Steel is a carbon steel enhanced with additional elements like chromium, nickel or molybdenum to improve its mechanical properties. This category is selected for CNC turning when applications require a superior strength-to-weight ratio, increased hardness or enhanced wear resistance compared to standard carbon steels. While its machinability is generally good, it can vary based on the specific alloying elements and heat treatment, often necessitating appropriate tooling and cutting parameters to achieve optimal surface finishes and dimensional accuracy. This makes it a critical material for the manufacturing of high-stress components such as gears, shafts and structural parts in automotive and aerospace prototyping and production. About Alloy Steel Available Alloy Steel AlloysAlloy Steel 4140 Alloy Steel 4340 Alloy Steel 1215 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

Mild Steel Mild Steel CNC MachiningMild Steel, also known as low-carbon steel, is a ductile and versatile material widely used in CNC turning for its excellent machinability and cost-effectiveness. Its soft nature allows for high material removal rates and easy fabrication of complex parts, making it suitable for high-volume production runs and prototyping. While it offers good weldability and strength for many applications, its low corrosion resistance often necessitates additional finishing processes. This manufacturability makes mild steel a fundamental choice for manufacturing brackets, frames, fixtures and other structural components where high strength-to-weight ratio is not the primary concern. About Mild Steel Available Mild Steel AlloysMild Steel 1018 Mild Steel 1045 Mild Steel A36 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide Electroless Nickel Plating |

|

Titanium Titanium CNC MachiningTitanium is a high-strength, low-weight metal known for its exceptional corrosion resistance and biocompatibility, making it a premium choice for demanding CNC turning applications. Its machinability is challenging due to low thermal conductivity and a tendency to work-harden, requiring specialized tooling, rigid setups and specific cutting parameters to manage heat and prevent galling. This impacts its manufacturability, often resulting in longer machining times, but is necessary for producing high-integrity components for aerospace, medical implants and automotive sectors. Despite these challenges, its unparalleled strength-to-weight ratio and performance in extreme environments make it critical for advanced prototyping and end-use part manufacturing. About Titanium Available Titanium AlloysTitanium Grade 1 Titanium Grade 2 Titanium Grade 5 As Machined As Machined (medium) As Machined (fine) Brushed Bead Blasting Polishing Powder Coating Black Oxide |

|

ABS ABS CNC MachiningABS (Acrylonitrile Butadiene Styrene) is a thermoplastic used widely for machining through CNC turning for its excellent impact strength, good dimensional stability and ease of post-processing. It offers good machinability, allowing for the efficient production of prototypes, jigs, fixtures and end-use parts with smooth surface finishes. While not as rigid as metals, its manufacturability is favored for applications requiring electrical insulation, light weight and the ability to be easily glued, sanded or painted after machining, making it a versatile material for functional prototyping and low-volume manufacturing. About ABS Available ABS FinishesAs Machined As Machined (medium) |

|

Acrylic Acrylic CNC MachiningAcrylic (PMMA) is a transparent thermoplastic valued in CNC turning for its optical clarity, weather resistance and ability to achieve a polished, glass-like finish. While it offers good machinability, its brittle nature requires precise tooling and appropriate feed rates to prevent cracking or chipping during the manufacturing process. This manufacturability makes it a suitable material for producing prototypes, light pipes, lenses, displays and various aesthetic components where transparency and a high-quality surface finish are critical. About Acrylic Available Acrylic FinishesAs Machined As Machined (medium) |

|

Delrin Delrin CNC MachiningDelrin (POM) is a thermoplastic known for its high stiffness, low friction and excellent dimensional stability, making it a highly suitable material for precision CNC turning. It offers exceptional machinability, allowing for the production of parts with tight tolerances and smooth surface finishes, often compared to metals. Its manufacturability is ideal for creating durable, low-wear components such as bearings, gears, insulators and fittings in both prototyping and end-use manufacturing. About Delrin Available Delrin TypesPOM-C POM-H As Machined As Machined (medium) |

|

HDPE HDPE CNC MachiningHDPE (High-Density Polyethylene) is a versatile thermoplastic known for its high impact strength, chemical resistance and low moisture absorption, making it a practical choice for CNC turning. It offers good machinability, though its relatively soft and waxy composition requires sharp tooling and appropriate speeds to achieve clean cuts and prevent deformation. This manufacturability supports the production of prototypes, chemical-resistant components, food-handling parts and low-friction industrial applications. While not suited for high-temperature environments, its durability and corrosion resistance make it widely used in both functional testing and end-use part manufacturing. About HDPE Available HDPE FinishesAs Machined As Machined (medium) |

|

Nylon Nylon CNC MachiningNylon (Polyamide) is a durable and versatile thermoplastic commonly used in CNC turning for its excellent wear resistance, high strength and good chemical resistance. It offers favorable machinability, though its tendency to absorb moisture can affect dimensional stability, requiring controlled machining environments to maintain tight tolerances. This manufacturability makes it suitable for producing functional prototypes, gears, bushings and other low-friction components that demand durability and reliability in both prototyping and end-use applications. About Nylon Available Nylon AlloysNylon 6/6 Nylon 6 (30% Glass Filled) As Machined As Machined (medium) |

|

Polycarbonate Polycarbonate CNC MachiningPolycarbonate is a thermoplastic known for its high impact strength, optical clarity and good heat resistance, making it a suitable material for CNC turning. While it offers decent machinability, its relatively soft and brittle nature requires sharp tooling and controlled machining parameters to prevent melting, chipping or internal stresses. This manufacturability supports the production of durable prototypes, protective covers, lenses and components requiring transparency and structural integrity in both prototyping and end-use part manufacturing. About Polycarbonate Available Polycarbonate FinishesAs Machined As Machined (medium) |

|

As Machined StandardAs machined parts feature visible tool marks from the CNC turning process with no secondary finishing operations applied. This standard CNC turning finish provides a functional surface straight from the machine. Learn more Finish Specifications

|

|

As Machined MediumAs machined medium parts undergo a controlled machining process that leaves a uniform surface with finer tool marks. This CNC turning finish results in a reduced surface roughness for improved functionality. Learn more Finish Specifications

|

|

As Machined FineA fine machined finish achieves minimal tool marks and a low surface roughness (Ra value) through precise CNC turning, suitable for functional precision parts without secondary finishing. Learn more Finish Specifications

|

|

Bead BlastingBead blasting uses fine glass or ceramic media to create a uniform matte texture and satin-like appearance, effectively hiding minor tool marks and imparting a clean, non-directional finish. Learn more Finish Specifications

|

|

BrushedBrushing is a mechanical finishing process that creates a consistent uniform satin grain, providing a uniform metallic appearance that masks minor surface imperfections. Learn more Finish Specifications

|

|

Chromate Conversion CoatingChromate conversion coating is a chemical process that converts the surface of aluminum or zinc parts into a corrosion-resistant layer, offering mild protection and optional decorative colors. Learn more Finish Specifications

|

|

PolishingPolishing is a mechanical finishing process that progressively abrades the surface to achieve a smooth, reflective, mirror-like finish, reducing surface roughness for improved corrosion and debris resistance. Learn more Finish Specifications

|

|

Powder CoatingPowder coating involves the application of electrostatically charged dry powder to a substrate, followed by heat curing to produce a uniform, resilient and visually appealing finish. Learn more Finish Specifications

|

|

Black OxideBlack oxide is a chemical conversion coating that creates a matte black finish on ferrous metals, providing mild corrosion resistance and minimal dimensional change. Learn more Finish Specifications

|

|

Electroless PlatingElectroless plating is a non-electrolytic, autocatalytic deposition method that applies a consistent nickel-phosphorus coating to enhance surface hardness, corrosion resistance and wear performance. Learn more Finish Specifications

|

|

Anodizing Type 2Type II anodizing involves an electrochemical reaction in a sulfuric acid electrolyte to produce a porous aluminum oxide coating, which improves corrosion and wear resistance and dye absorption. Learn more Finish Specifications

|

|

Anodizing Type 3 (Hard)Type III hard anodizing involves an electrochemical treatment in a low-temperature sulfuric acid bath under high current density, resulting in a thick, dense aluminum oxide coating that significantly enhances wear and corrosion resistance. Learn more Finish Specifications

|

CNC Turning Design Guidelines

Follow these critical parameters to ensure manufacturability across standard turning, Swiss machining and mill-turn operations. This table defines essential thresholds for wall thickness, length-to-diameter ratios and feature constraints preventing chatter, deformation and tooling failures while optimizing concentricity and surface finish. Align your designs with these process-specific recommendations to achieve first-pass success and cost efficiency for shafts, fittings and rotational components.

| Feature | Standard Turning | Swiss Machining | Mill-Turn |

|---|---|---|---|

| Wall Thickness | ≥0.8 mm (metals) ≥1.2 mm (plastics) |

≥0.5 mm (metals) ≥0.8 mm (plastics) |

≥0.8 mm (metals) ≥1.0 mm (plastics) |

| L/D Ratio | ≤8:1 (tailstock supported) | ≤20:1 (guide bushing) | ≤10:1 (live tool support) |

| Bore Depth | ≤5× diameter | ≤8× diameter | ≤6× diameter |

| Internal Corners | R0.3 mm+ | R0.2 mm+ | R0.3 mm+ |

| Thread Length | ≤3× diameter | ≤5× diameter | ≤4× diameter |

| Groove Width | ≥1.5× tool nose radius | ≥1.0× tool nose radius | ≥1.2× tool nose radius |

| Tolerances (Std) | ±0.075 mm | ±0.015 mm | ±0.015 mm |

| Tolerances (Tight) | ±0.015 mm | ±0.010 mm | ±0.015 mm |

| Surface Finish (Ra) | 1.6 μm (as-turned) | 0.8 μm (as-turned) | 1.2 μm (as-turned) |

| Undercuts | Limited to axial features | Axial + radial possible | Full radial/axial access |

Clarwe's Quality & Certifications Guarantee

All parts are validated in-house: Clarwe's Guarantee of Zero-Defect Parts

Every component is sourced from our vetted ISO/AS-certified manufacturing partners, then 100% physically inspected at our facility before shipment. Unlike others, we enforce a 3-stage custody protocol:

| Material Compliance: | We order and validate material certifications (RoHS, REACH, mill test reports) on your behalf. |

| In-House Verification: |

Dimensional accuracy checks via CMM, VMM, 2D height gauges and precision tools. Critical feature validation against your drawings (hole positions, thread fits, flatness). Visual inspection for surface defects, burrs and cosmetic flaws. |

| Final Certification: | Full documentation including material certs, CoCs and inspection logs. |

| We guarantee: | ±0.020 mm tolerances on all

shipped parts (validated in-house). Zero paperwork gaps - we manage all supplier certifications. 100% physical custody - no direct supplier shipments delivering zero-defect compliance from prototype to 100,000+ part production runs. |

Why Choose Clarwe for CNC Turning Services?

Precision engineered parts demand a partner who blends cutting-edge technology with relentless reliability. We deliver complex turned, mill-turn and Swiss-machined components faster and more accurately than competition, thanks to our direct-access engineering team and hyper-responsive manufacturing ecosystem. With over 200 ISO 9001 and AS9100-certified manufacturing partners worldwide, we scale seamlessly from single-piece prototypes to production runs of more than 100,000 parts, while maintaining tolerances down to ±0.0005 inches and providing medical and aerospace-grade certifications such as ISO 13485 and AS9100. Our intuitive digital dashboard gives you real-time visibility into every order, allowing you to track progress, approve revisions, manage deliveries and download certifications with a single click, eliminating the need to chase suppliers through opaque platforms.

We guarantee on-time delivery (99.7% track record) and zero-surprise pricing, backed by a 100% quality commitment: if a part fails inspection, we remake it at our cost and expedite shipping. You get enterprise-grade capabilities, including Swiss machining for micro-components, 5-axis mill-turn for complex geometries and anodizing, powder coating or any other finish, all without the complexity. Experience the difference: upload your design today for Online Quote with no hidden fees.

Clarwe's Platform Advantage

Our integrated dashboard delivers end-to-end project command, streamlining workflows while ensuring transparency at every stage. Experience seamless coordination from initial request to final delivery, all within a single secure interface.

Submit & Configure

| RFQ Initiation |

Upload CAD files (STEP, IGES, SLDPRT) and drawings Specify requirements: materials, tolerances, finishes, inspection protocols Request custom documentation: material certs, CMM reports, customs forms |

| Real-Time Quoting |

Receive online DFM analysis with cost drivers flagged Adjust configurations (e.g., material substitutions) to optimize pricing |

Order Execution & Oversight

| Document Management |

Submit customs declarations, commercial invoices and HS codes Upload purchase orders or approve terms for payment Access digital invoices with tax/line-item breakdowns |

| Production Intelligence |

Track progress and updates View Shop floor photos/videos Access Inspection reports, quality documents and Material certifications Monitor shipping status with carrier integrations |

Proactive Collaboration & Support

| Engineer Engagement |

Send technical queries and status enquiries to our engineers via encrypted chat Receive resolution timelines for technical queries |

| Quality Assurance Hub |

Access pre-shipment documentation: First-article inspection reports, dimensional reports and quality

documents Approve/reject deliverables via annotated media |

| Post-Delivery Excellence |

Initiate reorders with one-click cloning Log support tickets for non-conformances Archive project history (drawings, certs, comms) for audits |

Industries specialized

Aerospace

Automotive

Consumer Products

Medical

Ready to get started?

Frequently Asked Questions about CNC Turning

CNC turning rotates a workpiece while a stationary cutting tool removes material to create cylindrical parts like shafts, bushings or pins. Unlike milling (which moves the tool around a stationary workpiece), turning excels at high-precision axisymmetric components. Our automated lathes achieve ±0.015 mm tolerances and complex geometries 40% faster than manual alternatives.

We machine 50+ materials, including:

Standard tolerance: ±0.075 mm. Tight-tolerance capability: ±0.010mm for critical features like sealing surfaces or bearing seats. We use ISO 9001-certified processes with in-process CMM verification to ensure consistency.

Yes. We offer:

Upload STEP, IGES, DXF or SolidWorks® files for online quotes. For 2D drawings, include GD&T callouts, material specs, and surface finish requirements. Our AI-powered platform analyzes designs in <2 minutes and provides free DFM feedback.

Rigorous 4-step process:

1. In-process checks: Real-time monitoring with calibrated gauges.

2. Final inspection: CMM, VMM.

3. Material certification: Traceability for alloys/plastics.

4. Compliance docs: Certificates of Conformity (AS9100 available).

Yes. Our Swiss-type and multi-axis lathes support:

Get a Online Quote in <2 hours:

1. Click here to upload CAD file

2. Select material, quantity, tolerances

3. Add finishing/assembly options

Receive a detailed quote with cost breakdown in <2 hours.

Standard CNC Turning (Lathe Machining) is ideal for parts with a lower Length-to-Diameter (L/D) ratio (typically < 6:1). The workpiece is held in a chuck and the tool moves to cut features. It's perfect for bushings, flanges and connectors.

Swiss Screw Machining is designed for long, slender and complex parts with high L/D ratios (up to 20:1). The material bar is guided by a bushing right next to the cutting tools, providing immense support and eliminating deflection. This allows for ultra-tight tolerances (±0.005 mm) on features like medical pins, shafts and miniature components.

Live tooling refers to CNC lathes where the tools can not only turn but also rotate and perform milling, drilling, and tapping operations. This "mill-turn" capability allows us to machine complex parts—like a housing with off-axis holes or a flange with slots—complete in a single setup. This eliminates the cost, lead time and alignment errors associated with moving a part to a second milling machine.

This is a common challenge that we are expertly equipped to handle. For standard lathes, we use tailstocks and steady rests to support the workpiece. For extremely long and thin parts, we recommend Swiss screw machining, which is specifically designed to prevent deflection and chatter by supporting the bar stock directly at the point of cutting, ensuring exceptional concentricity.

We guarantee concentricity through:

- Precision Workholding: Using certified collets and chucks.

- In-Process Verification: On-machine probing to check runout.

- Final Validation: 100% in-house CMM inspection to measure true positional and geometric tolerances like concentricity, cylindricity and roundness per your drawing's GD&T callouts.

Yes. We specialize in machining complex internal features using specialized tooling:

- Deep Hole Boring: Using fine-boring bars and high-pressure coolant for depths exceeding 10x diameter.

- Internal Threading: For standard and custom thread forms.

- Internal Grooving: For snap-ring and O-ring grooves.

We provide DFM feedback on minimum recommended bore diameters and depths during the quoting process.

We offer a complete suite of post-processing to meet functional and cosmetic requirements:

- Anodizing (for aluminum parts)

- Passivation (for stainless steel corrosion resistance)

- Plating (Nickel, Zinc, Electroless Nickel)

- Heat Treating (Annealing, Hardening, Tempering)

- Deburring & Polishing to specific surface finishes (e.g., Ra 0.4 μm)

Our connected manufacturing model provides significant advantages:

- Lead Times: 1-3 days for prototypes, 5-10 days for production runs. We are often faster as we avoid multi-vendor coordination delays.

- Pricing: By optimizing bar stock usage and nesting multiple parts, we offer 10-20% more competitive pricing on volume orders. Our quotes include material certifications and standard inspection reports at no extra cost.

Absolutely. Our processes and partner network are certified to the most stringent industry standards, including:

- ISO 13485 for medical devices and implants

- AS9100D for aerospace and defense components