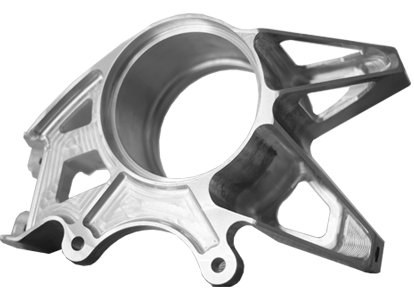

CNC Machining

Clarwe's CNC machining services provide precision 3, 4 and 5-axis CNC milling, CNC turning and CNC EDM for complex geometries, tight-tolerance (±0.02 mm) features and production-grade surface finishes across prototypes and high-volume custom parts.

- • 3, 4 and 5-axis CNC milling and multi-axis CNC turning for prismatic and cylindrical components.

- • Wire and sinker EDM for hard-to-machine materials, sharp internal corners, fine features and complex profiles that conventional cutting tools cannot reach.

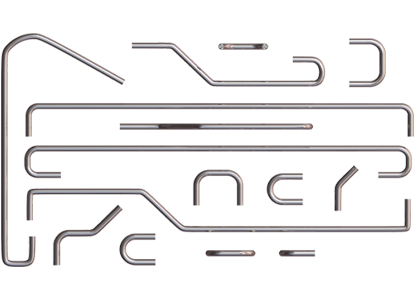

CNC Tube Bending

Clarwe’s tube bending services support tight-radius, multi-plane tube geometries for structural and fluid-handling systems. We focus on bend quality, dimensional accuracy and repeatability across batches.

- • Mandrel and roll bending for reduced distortion and ovality.

- • Complex multi-plane bends with accurate angle and length control.

- • Tube materials including mild steel, stainless steel and non-ferrous alloys.

Sheet Metal Fabrication

Clarwe’s sheet metal fabrication services cover laser cutting, bending, forming, welding and assembly for both prototype and production-grade parts.

- • CNC laser cutting, punching, bending, welding and hardware insertion.

- • 50+ metals and 30+ finishes including powder coating, painting, plating and anodizing.

- • Low-volume prototypes through to scheduled production with repeatable quality.

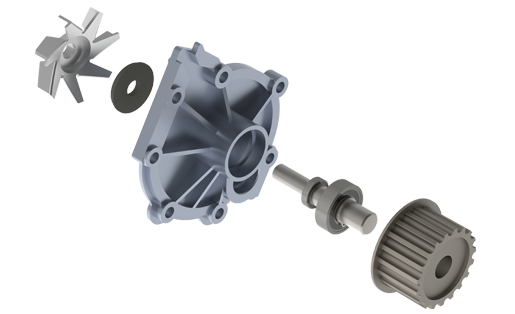

Gear Manufacturing

Our gear manufacturing services cover precision gears for automotive, industrial and motion-control applications. We combine machining, heat treatment and grinding to deliver gears that meet demanding standards.

- • Spur, helical, bevel and worm gears via hobbing, shaping, broaching and CNC milling.

- • Heat treatment, grinding, lapping and finishing to AGMA/DIN-equivalent levels.

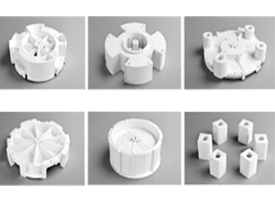

Urethane Casting

Clarwe's urethane casting services deliver injection-molded-like quality without hard tooling, ideal for functional prototypes and low-volume production runs.

- • 50+ urethane materials simulating common production plastics and elastomers.

- • Class-A cosmetic finishes, textures, overmolding and inserts where required.

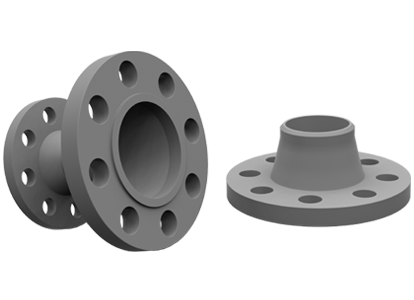

Injection Molding

Clarwe’s injection molding services help you go from prototype tooling to production tooling with DFM-led design support. We support functional prototypes, bridge tooling and high-volume molding for consumer, industrial and automotive components.

- • DFM review on parting lines, draft, gating, wall thickness and material choice.

- • Rapid tooling and hardened steel tooling options depending on volume and lifetime.

- • Integration with QA/QC for regulated and safety-critical parts where required.

CNC Laser Cutting

Clarwe provides CNC laser cutting services for flat profiles and complex geometries in metals and select non-metals. Clean edges, tight kerf control and excellent repeatability make it ideal for both one-offs and nested production runs.

- • CO2, fibre and Nd:YAG laser cutting, thickness ranges by material.

- • High-accuracy nested cutting for efficient material utilization.

- • Integrated with bending, welding and finishing where required.

Surface Finishes

Clarwe offers a wide catalog of surface finishes and secondary operations so you receive parts production-ready.

- • Finishes: anodizing, powder coating, painting, plating, bead blasting, polishing and more (material dependent).

- • Final inspection aligned to finished-part specs, not just pre-finish dimensions.

Assembly and Value-Added Services

Clarwe offers assembly services so your parts arrive closer to installation-ready. We manage parts, fasteners, fixtures and QA in one workflow.

- • Mechanical sub-assemblies, welding assemblies and box builds (application dependent).

- • Kitting, labelling and packaging per your production requirements.

- • Optional testing and inspection to your specifications.

Offline CNC Programming

Clarwe's offline CNC programming services create production-ready programs for your 3, 4, 5-axis milling centers and 2 and 3-axis CNC lathes, so your operators can focus on more pressing work.

- • Support for Fanuc, Siemens, Heidenhain and other leading controllers.

- • Optimized toolpaths for cycle time, tool life and surface finish on complex parts.

- • Detailed setup sheets, workholding notes and simulation screenshots with every program.

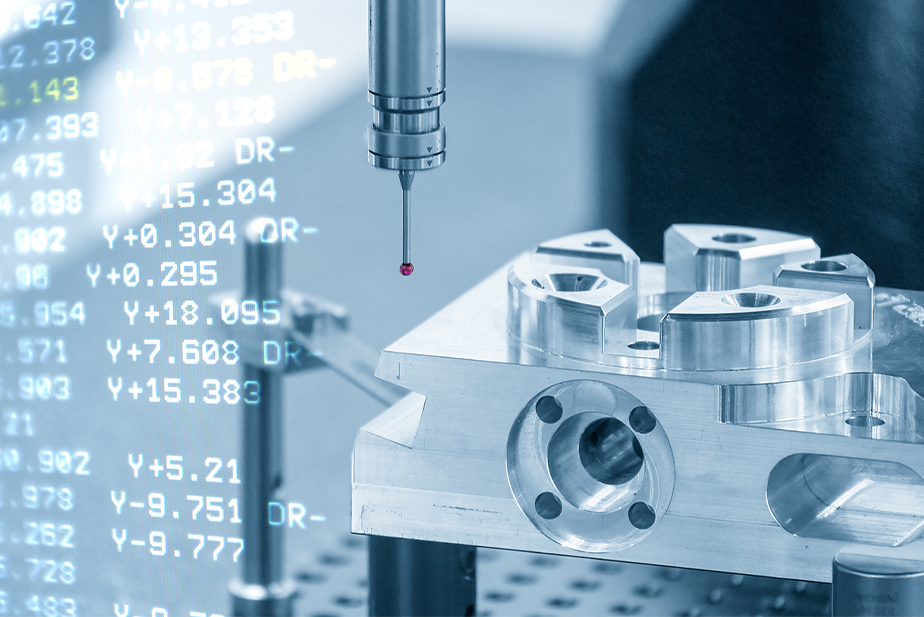

Offline CMM Programming

Clarwe’s offline CMM programming services, using digital twins of your CMM and software like PC-DMIS or CALYPSO, we convert your CAD and GD&T into collision-free, production-ready programs-without tying up your machine.

- • AS9100-grade offline CMM programming for aerospace, medical, automotive and industrial parts.

- • Virtual simulation of probe paths, fixtures and clearances with accuracy.