About Sheet Metal Fabrication

Sheet Metal Fabrication Services

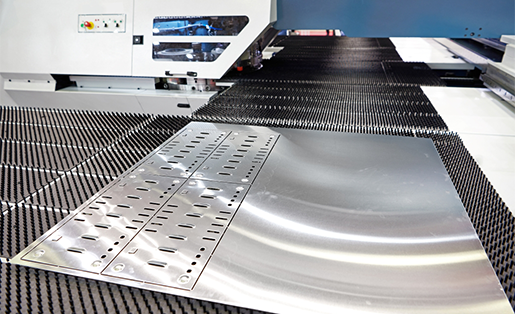

CNC Laser Cutting

Quick QuoteLeverage high-power fiber or CO₂ lasers guided by advanced computer controls to achieve precision you can rely on – cutting complex patterns and complex contours in materials from 0.024" to 0.750" (0.6–19mm) thick, including aluminum, stainless steel, carbon steel, and brass. Our process delivers exceptional accuracy with tolerances of ±0.005" (±0.127mm) and smooth edges (Ra 25–125 µin), minimizing secondary finishing while ensuring consistent, functional parts with negligible heat distortion. With kerf widths as narrow as 0.006" (0.15mm), we provide dependable quality for both rapid prototypes and high-volume production – turning complex designs into reality with repeatable precision and material efficiency.

CNC Waterjet Cutting

Quick QuoteExperience truly worry-free cutting of virtually any material – from sensitive metals like copper and titanium to composites and thick plates up to 6" (152mm) – using ultra-high-pressure water (60,000+ PSI) mixed with abrasive garnet. Our process eliminates thermal distortion entirely, preserving material integrity while achieving ±0.003" (±0.076mm) accuracy and controlling taper to <1° even on thick sections. With virtually no heat-affected zone (HAZ), our waterjet services provide reliable choice for complex geometries and heat-sensitive applications where traditional methods fail, ensuring perfectly flat, stress-free parts ready for critical use.

CNC Plasma Cutting

Quick QuoteWhen speed and value matter for thicker electrically conductive metals – especially mild steel in the 0.125"–1.5" (3–38mm) range – our computer-controlled plasma cutting delivers optimized performance. The process generates a high-velocity jet of ionized gas to rapidly profile parts with ±0.020" (±0.5mm) tolerances and a controlled heat-affected zone (HAZ) of 0.03"–0.12" (0.76–3mm). This proven, cost-effective approach maximizes throughput for applications where precision needs are balanced with production efficiency, giving you robust, consistent quality without over-engineering costs.

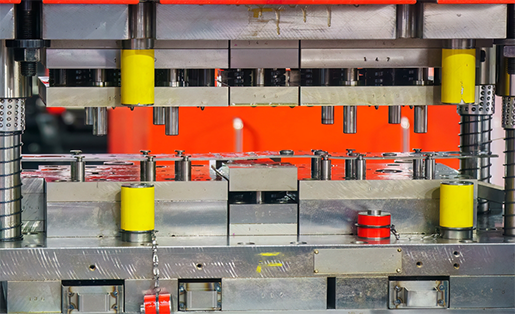

CNC Turret Punch Press

Quick QuoteMaximize production efficiency for medium to high-volume sheet metal parts with our automated turret punch technology, handling sheets up to 60"×120" in materials 0.020"–0.250" thick. Using programmable multi-tool turrets, we economically create complex patterns of holes, slots, louvers, notches, embosses, and custom forms while achieving ±0.004" (±0.1mm) positional accuracy at speeds up to 600 hits/minute. Integrated in-die tapping and burr removal delivers ready-to-assemble components – eliminating secondary operations and ensuring consistent, precision-engineered parts for your demanding applications.

CNC Sheet Metal Bending

Quick QuoteAchieve complex 3D geometries and precise angles – from simple channels to complex enclosures – with our computer-controlled press brakes featuring ±0.004" (±0.1mm) repeatability and ±1° angular tolerance. We deliver consistent, repeatable bends across production batches by combining precision tooling with advanced springback compensation, expertly calibrated for material-specific behaviors like stainless steel (K-factor 0.35–0.45) and aluminum (K-factor 0.40–0.50). Capable of forming standard bend radii from 0.010"–0.750" (0.25–19mm) with minimum flange lengths of 4× material thickness, this ensures first-part correctness and reduces scrap rates for your most demanding applications.

Press Tools (Stamping)

Quick QuoteUnlock unmatched cost efficiency and dimensional consistency for high-volume production runs exceeding 10,000+ units with our stamping expertise. Using mechanical or hydraulic presses (20–200+ tons), we perform precision operations – including blanking, piercing, deep drawing (depths ≤5× material thickness), forming, and coining – in progressive or transfer dies that deliver tolerances down to ±0.004" (±0.1mm). This method transforms raw coil or sheet metal into identical, complex parts at breakthrough per-unit pricing, making it the smartest path to market for components demanding rigorous geometric repeatability, tight form specifications, or high-speed assembly readiness.

Sheet Metal Fabrication Tolerances

| Tolerance Type | CNC Laser Cutting | CNC Waterjet Cutting | CNC Plasma Cutting | CNC Turret Punch Press | CNC Sheet Bending | Press Tools (Stamping) |

|---|---|---|---|---|---|---|

| Linear Dimensions | ±0.005" (±0.13mm) | ±0.003" (±0.08mm) | ±0.020" (±0.5mm) | ±0.004" (±0.1mm) | ±0.005" (±0.13mm) | ±0.004" (±0.1mm) |

| Hole Position | ±0.003" (±0.08mm) | ±0.005" (±0.13mm) | ±0.030" (±0.76mm) | ±0.005" (±0.13mm) | N/A | ±0.005" (±0.13mm) |

| Angular (Bends) | N/A | N/A | N/A | N/A | ±0.5° | ±1° (progressive dies) |

| Edge Straightness | 0.004"/in (0.1mm/100mm) | 0.002"/in (0.5mm/100mm) | 0.040"/in (1mm/100mm) | 0.006"/in (0.15mm/100mm) | N/A | 0.004"/in (0.1mm/100mm) |

| Surface Finish (Ra) | 125 μin (3.2μm) | 200 μin (5.1μm) | 500 μin (12.7μm) | 250 μin (6.3μm) | N/A | 32 μin (0.8μm) |

| Bend-to-Hole Distance | N/A | N/A | N/A | N/A | ±0.012" (±0.3mm) | ±0.012" (±0.3mm) |

| Flatness (Post-Cut) | 0.005"/12" (0.13mm/300mm) | 0.002"/12" (0.05mm/300mm) | 0.030"/12" (0.76mm/300mm) | 0.010"/12" (0.25mm/300mm) | N/A | 0.001"/12" (0.03mm/300mm) |

|

AluminumLightweight, corrosion-resistant, exhibits high strength-to-weight ratio and excellent thermal and electrical conductivity. Learn more Aluminum Alloys

|

|

CopperHighly conductive, malleable metal with excellent thermal and electrical conductivity and resistance to corrosion. Learn more Copper Alloys Copper Finishing Options |

|

Stainless SteelCorrosion-resistant alloy with excellent strength and durability, primarily composed of iron, chromium, and nickel. Learn more Stainless Steel Alloys Stainless Steel Finishing Options |

|

Mild SteelMild steel, also known as low-carbon steel. Mild steel is primarily characterized by having a carbon content of less than 0.2% by weight. Learn more Mild Steel Alloys Mild Steel Finishing Options |

|

Bead BlastingParts are glass bead blasted which will result in a textured satin-like finish. Learn more Finish Specifications

|

|

BrushedParts are manually brushed with sand paper to improve surface roughness. Learn more Finish Specifications

|

|

Chromate Conversion CoatingChromate Conversion Coating will be applied to parts with As Machined finish. Learn more Finish Specifications

|

|

PolishingParts are manually polished resulting in a smooth surface roughness. Learn more Finish Specifications

|

|

Powder CoatingEconomical, durable and long-lasting finish with many color options. Learn more Finish Specifications

|

|

Black OxideBlack Oxide coating is applied on As Machined parts to improve wear resistance. Learn more Finish Specifications

|

|

Electroless PlatingElectroless plating is applied to As Machined finish parts. Learn more Finish Specifications

|

|

Anodizing Type 2Anodizing Type 2 is applied on As Machined parts to improve wear resistance. Learn more Finish Specifications

|

|

Anodizing Type 3 (Hard)Anodizing Type 3 is applied on As Machined parts to form a highly durable coating. Learn more Finish Specifications

|

Secondary Processes & Finishing

Transform fabricated components into fully functional, assembly-ready products with our comprehensive secondary operations. Our precision welding capabilities include TIG (0.020"–0.250" welds) for critical joints, high-speed MIG (>24"/min) for structural efficiency, and resistance spot welding (<0.5ms cycle time) for rapid joining. We seamlessly integrate hardware – PEM studs, nuts, and standoffs installed with ±0.010" (±0.25mm) positional accuracy – while our precision-controlled deburring ensures safety and fitment. Final surface treatments like powder coating (1.5–4 mil), Type II/III anodizing (0.0001"–0.002"), passivation, and silk screening deliver consistent, production-ready quality that meets aesthetic and durability requirements straight from our facility, accelerating your assembly timeline while eliminating secondary logistics.

Sheet Metal Fabrication Design Guidelines

| Design Feature | CNC Laser Cutting | CNC Waterjet Cutting | CNC Plasma Cutting | CNC Turret Punch Press | CNC Sheet Bending | Press Tools (Stamping) |

|---|---|---|---|---|---|---|

| Min Hole/Slot Size | ≥ Material Thickness (0.024" min) | ≥ 1.2× Thickness (0.036" min) | ≥ 1.8× Thickness | ≥ Material Thickness (0.020" min) | N/A | ≥ Material Thickness |

| Edge‑to‑Hole Distance | ≥ 1× Thickness | ≥ 2× Thickness | ≥ 2× Thickness | ≥ 2× Thickness | ≥ 2.5× Thickness + Radius | ≥ 2× Thickness |

| Bend Relief Width | N/A | N/A | N/A | N/A | ≥ Material Thickness | ≥ Material Thickness |

| Min Flange Length | N/A | N/A | N/A | N/A | 4× Thickness + Radius | 3× Thickness |

| Corner Radius | ≥ ⅓ Thickness | ≥ 0.020" | ≥ 0.040" | ≥ 0.020" | ≥ Material Thickness | ≥ 0.010" |

| Tolerance (Typical) | ±0.005" | ±0.003" | ±0.020" | ±0.004" | ±0.5° Angular | ±0.002" |

| K‑Factor (Bend Allow.) | N/A | N/A | N/A | N/A | 0.35–0.45 (SS), 0.40–0.50 (Al) | 0.30–0.35 (Progressive) |

| Draft Angle | N/A | N/A | N/A | N/A | N/A | ≥ 3° per side |

| Form Depth (Emboss) | N/A | N/A | N/A | ≤ 60% Thickness | N/A | ≤ 5× Thickness |

| Material Thickness Range | 0.024"–0.750" | 0.024"–6.0" | 0.125"–1.5" | 0.020"–0.250" | 0.020"–0.500" | 0.010"–0.250" |

Quality & Certifications Module

Certified Precision, Validated In-House: Your Guarantee of Zero-Defect Parts

Every component is sourced from our vetted ISO/AS-certified manufacturing partners, then 100% physically inspected at our facility before shipment. Unlike others, we enforce a 3-stage custody protocol:

| Material Compliance: | We order and validate material certifications (RoHS, REACH, FDA, mill test reports) on your behalf. |

| In-House Verification: |

Dimensional accuracy checks via CMM, VMM, 2D height gauges (±0.01 mm), and precision tools. Critical feature validation against your drawings (hole positions, thread fits, flatness). Visual inspection for surface defects, burrs, and cosmetic flaws. |

| Final Certification: | Full documentation including material certs, CoCs, and inspection logs. |

| We guarantee: | ±0.1 mm tolerances on all

shipped parts (validated in-house). Zero paperwork gaps – we manage all supplier certifications. 100% physical custody – no direct supplier shipments delivering zero-defect compliance from prototype to 100,000+ part production runs. |

Why Choose Clarwe?

We combine cutting-edge technology with unwavering reliability to simplify custom manufacturing. Our seamless platform

offers quick quoting, real-time project tracking, and an intuitive dashboard that streamlines order management from

prototype to high-volume production—eliminating the friction of traditional sourcing. With access to a vast ISO

9001:2015-certified manufacturer network, we guarantee capacity for projects of any scale while maintaining rigorous

quality control across CNC laser cutting, waterjet, plasma, turret punching, precision bending, stamping, and finishing

services.

Every part we deliver is backed by a comprehensive quality guarantee, ensuring dimensional accuracy, material integrity, and on-time fulfillment. Unlike fragmented solutions, our integrated solutions (including welding, PEM insertion, and powder coating) mean your components arrive assembly-ready—saving time, reducing supply chain complexity, and giving you a single point of accountability for critical results. Experience the blend of digital agility and industrial expertise that makes us the trusted partner for aerospace, automotive, and tech innovators.

The Platform Advantage - Unified Oversight for Online Manufacturing

Our integrated dashboard delivers end-to-end project command—streamlining workflows while ensuring transparency at every stage. Experience seamless coordination from initial request to final delivery, all within a single secure interface.

Submit & Configure

| RFQ Initiation |

Upload CAD files (STEP, IGES, SLDPRT) and drawings Specify requirements: materials, tolerances, finishes, inspection protocols Request custom documentation: material certs, CMM reports, customs forms |

| Real-Time Quoting |

Receive instant DFM analysis with cost drivers flagged Adjust configurations (e.g., material substitutions) to optimize pricing |

Order Execution & Oversight

| Document Management |

Submit customs declarations, commercial invoices, and HS codes Upload purchase orders or approve terms for payment Access digital invoices with tax/line-item breakdowns |

| Production Intelligence |

Track progress and updates View Shop floor photos/videos Access Inspection reports, quality documents and Material certifications Monitor shipping status with carrier integrations |

Proactive Collaboration & Support

| Engineer Engagement |

Send technical queries and status enquiries to our engineers via encrypted chat Receive resolution timelines for technical queries |

| Quality Assurance Hub |

Access pre-shipment documentation: First-article inspection reports, dimensional reports and quality documents Approve/reject deliverables via annotated media |

| Post-Delivery Excellence |

Initiate reorders with one-click cloning Log support tickets for non-conformances Archive project history (drawings, certs, comms) for audits |

Industries specialized

Aerospace

Automotive

Consumer Products

Medical

Frequently Asked Questions

Absolutely. We specialize in scalable precision:

Access real-time DFM expertise:

Yes – a key advantage over services outsourcing post-processing:

Fully compliant with:

Through:

We accept all major CAD file formats, including STEP, IGES, DXF, and DWG, along with native SolidWorks, Inventor, and Fusion 360 files. Our AI-powered platform automatically analyzes your design for manufacturability (DFM), providing instant feedback on potential issues like tight tolerances, hole sizes, and bend radii to prevent delays and ensure your part is optimized for cost-effective production from the very first quote.

Quality is integral to our process. We partner with a network of ISO 9001:2015 certified manufacturing facilities and enforce a rigorous multi-stage inspection protocol. This begins with raw material certification, includes in-process checks using precision tools like CMMs and laser scanners to hold tolerances as tight as ±0.002" for stamping, and ends with a final quality audit before shipment. This vertically integrated approach guarantees consistent, high-quality results that surpass the capabilities of distributed, third-party networks.

Our on-demand model is built for speed without compromising quality. We typically ship prototypes within 1-5 business days, significantly faster than industry averages. For production volumes, lead times are scalable based on quantity and complexity, but our integrated in-house capabilities—from laser cutting and bending to welding and powder coating—eliminate the coordination delays common with other services, ensuring a seamless and efficient transition from prototype to high-volume runs of 10,000+ units.

Absolutely. Unlike many services that outsource finishing, we provide a comprehensive, end-to-end solution entirely under one roof. This includes CNC machining, precision TIG and MIG welding, hardware insertion (PEM studs, nuts) with ±0.010" accuracy, and a full range of surface finishes from MIL-spec anodizing to powder coating. This means your parts arrive fully assembly-ready, saving you the time, cost, and logistical hassle of managing multiple vendors.

Yes, we are fully equipped to serve highly regulated industries. Our processes and partners comply with stringent standards including AS9100 for aerospace, ISO 13485 for medical devices, and EN 1090 for structural steelwork. We provide full material traceability (MTRs) and first-article inspection reports (FAIR) as standard upon request, giving you the necessary documentation for your quality and compliance requirements.

We are committed to complete transparency. Our online quoting platform provides real-time, detailed pricing based on your design, material, and quantity, with no hidden platform surcharges. For high-volume projects, our advanced nesting algorithms and in-house efficiencies allow us to offer volume discounts up to 30%, providing exceptional value. You will always see the final cost before you commit to an order.

You have full visibility into your order's status through our intuitive online dashboard. Unlike basic status trackers, our system provides machine-level updates, allowing you to see when your parts are in laser cutting, bending, finishing, or final inspection. You can also directly access and download quality certification documents and shipping notifications, all from a single platform.