Sandblasting is an abrasive surface treatment that uses high-pressure air or water to propel abrasive media, such as steel grit or aluminum oxide, onto a surface. This process effectively removes rust, paint, scale and contaminants while enhancing adhesion for coatings and improving surface texture. It is widely used in industries likeautomotive , construction and manufacturing to clean, prepare or restore metal, concrete and wood surfaces.Abrasive media vary in hardness, shape and size (typically #120 to #220), affecting the final surface quality. Steel grit (40-65 HRC) is commonly used for its angular shape, making it ideal for cleaning, etching and surface preparation. Sandblasted parts achieve a clean, matte finish that enhances coating adhesion. Proper safety measures, including protective gear and ventilation, are essential to minimize dust exposure.

Stainless steel ,aluminum ,brass ,plastics , glass, wood, composites

Ra 1.6–6.3 µm (varies with media and pressure).

Matte, satin or frosted finish depending on media type.

Cosmetic options available on request.

Material removal ~0.01–0.05 mm; minimal thickness impact.

Fine to coarse (e.g., 80–220 grit equivalent, based on media size).

6061 T6, 6082, 7075-T6, 5083-H111, 6063, 5052, 2024-T351, 7050, 2017A, 6082-T651, 7075-T651, 2014, 6061-T651, 7075-T7351, 6082-T6, 2014-T6, 6063-T5, 6063-T6, 5083-H32, 5052-H32

A2 Tool steel, D2 Tool steel, A3 Tool Steel, O1 Tool Steel, S7 Tool Steel, H13 Tool Steel

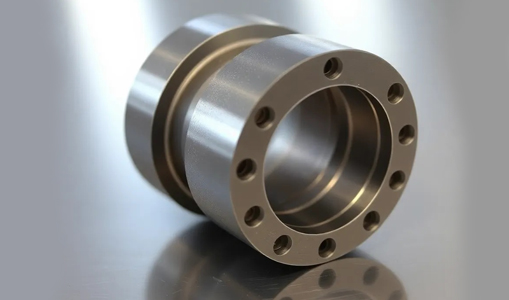

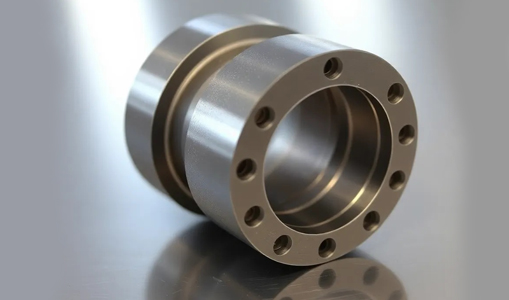

932 Bearing Bronze , 954 Bearing Bronze, 544 Bearing Bronze

Ranges from 0.5–7.0 µm, depending on media and pressure.

Garnet, aluminum oxide, steel grit, glass beads, walnut shells and plastic media, each suited for different applications.

Air pressure, abrasive type, particle size, nozzle design and impact angle.