Introduction

Types of Plastics Used

1.Thermoplastics

2.Thermosetting plastics

Thermoplastics

These plastics can be reshaped repeatedly without going through chemical changes because they soften when heated and solidify when cooled. The common thermoplastics along with their properties are listed below:| Plastic | Properties |

|---|---|

| Polyethylene | Lightweight, flexible, chemical resistant |

| Polymethyl Methacrylate | Optical clarity, scratch resistance, weather resistance |

| Polypropylene | High melting point, chemical resistance |

| Polyphenylene Sulfide | High temperature resistance, chemical resistance |

| Polyvinyl Chloride | Versatile, durable, flame resistant |

| Polyethylene Chlorotrifluoroethylene | Excellent chemical resistance, non-stick surface |

| Polyvinylidene Fluoride | Chemical resistance, high purity, UV resistance |

| Polyoxymethylene | Low friction, high stiffness, excellent dimensional stability |

| Polycarbonate | Transparent, impact resistant, heat resistant |

| Polyethylene Terephthalate | Clear, strong, lightweight, recyclable |

| Acrylonitrile Butadiene Styrene | Tough, impact resistant, good surface finish |

| Polystyrene | Lightweight, rigid, good insulator |

Thermosetting plastics

In contrast to thermoplastics, thermosetting plastics form a rigid, cross-linked structure when heated, irreversibly curing or hardening. They cannot be remelted or reformed once they have set. The common thermosetting plastics along with their properties are listed below:| Plastic | Properties |

|---|---|

| Epoxy Resin | Excellent adhesion, chemical resistance, high strength |

| Phenolic Resin | High temperature resistance, excellent fire resistance |

| Epoxide Phenolic Resin | Excellent heat resistance, chemical resistance |

| Vinyl Ester Resin | Corrosion resistance, good mechanical properties |

| Polyester Resin | Good weather resistance, high strength-to-weight ratio |

| Silicone Rubber | Heat resistance, flexibility, electrical insulation |

| Urea-Formaldehyde | Hard and scratch-resistant, good electrical properties |

| Melamine Resin | Scratch resistance, chemical resistance, decorative surfaces |

| Diallyl Phthalate | High temperature resistance, dimensional stability |

| Bakelite | High mechanical strength, electrical insulation |

| Alkyd Resin | Quick drying, good adhesion, weather resistance |

| Polyurethane Resin | Abrasion resistance, elasticity, insulation properties |

Different types of plastic fabrication methods

| Fabrication Method | Working Principle | Suitable Plastics | Applications |

|---|---|---|---|

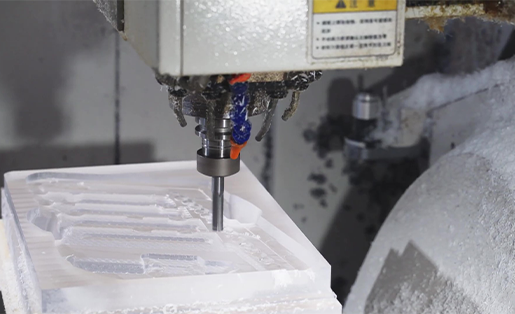

| Plastic CNC Machining | Subtractive manufacturing method that involves placing a solid block of plastic against a moving cutting tool that removes material from the block. | ABS, PC, PP, POM, Nylon | Prototypes, custom parts, gears, brackets, housings |

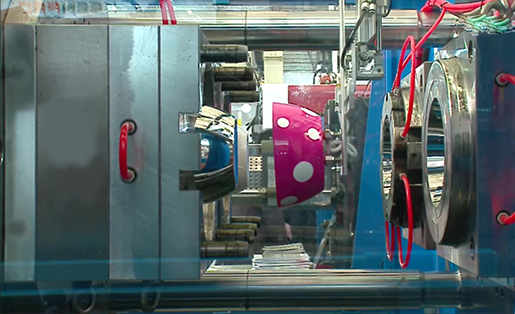

| Plastic Injection Molding | Plastic is melted and then injected into a mold, where it cools and takes on its final form. | PP, PE, PS, ABS, PC, Nylon | Consumer goods, automotive parts, toys, medical devices, containers |

| Filament Winding | Continuous reinforcement fibers, typically impregnated with a resin, are wound around a rotating mandrel. | Glass fiber, carbon fiber | Pressure vessels, pipes, golf clubs, bicycle frames |

| Compounding Plastic Fabrication | Taking basic, raw plastic material and customizing it with various additives to achieve color, property and performance requirements. | Various thermoplastics | Custom polymer blends, enhanced material properties for specific applications |

| Plastic Lamination Fabrication | Layering several sheets of material and joining them with adhesives, pressure, or heat. | Various thermoplastics | Laminated sheets, countertops, safety glass, packaging materials |

| Resin Transfer Molding | The fibers are immersed and treated by injecting resin into a closed mold containing a dry fiber preform. | Epoxy, polyester | Aerospace components, automotive parts, wind turbine blades |

| Reaction Injection Molding | Combining two liquid ingredients to create a solid plastic part through a chemical reaction in the mold. | Polyurethane, epoxy | Automotive bumpers, enclosures, industrial casings |

| Compression Molding | To shape and cure the material, it is placed in a heated mold cavity and compressed. | Thermosets, composites | Electrical components, automotive parts, cookware handles |

| Rotational Molding | Plastic is heated in a rotating mold to ensure uniform thickness and coating as it melts and forms the part. | PE, PVC, Nylon | Tanks, containers, toys, kayak hulls |

| Plastic Welding | Fusing plastic components together by applying pressure or heat. | PVC, PP, PE, PC, ABS | Tanks, piping systems, automotive components, fabric structures |

| Blow Molding | Hollow parts are created inside a mold by blowing air into heated plastic. | PE, PP, PVC, PET | Bottles, containers, automotive ducts, fuel tanks |

| Plastic Extrusion | Melted plastic is forced through a shaped die to produce continuous, uniformly cross-sectional profiles. | PVC, PE, PP, ABS | Pipes, profiles, window frames, weatherstripping |

| Thermoforming Fabrication | Using a vacuum or pressure, form the plastic sheet over a mold after heating it until it becomes fluid. | ABS, PC, PS, PVC, PETG | Packaging, trays, panels, automotive interior parts |

| Die Cutting Fabrication | Cutting shapes from plastic sheets using a die with sharp edges. | Various thermoplastics | Gaskets, labels, packaging inserts, electronic components |

| Pultrusion Fabrication | Fibers are pulled through a resin bath and a heated die to produce strong, continuous profiles. | Glass fiber, carbon fiber | Structural components, rods, beams, gratings |

| Forging Fabrication | Shaping the plastic using compressive forces in a die to form the material. | Thermoplastics, thermosets | Gears, structural components, medical devices |

| Vacuum Casting | Resin is poured under vacuum into a mold to produce fine details and remove air bubbles. | Polyurethane, silicone | Prototypes, short-run production, small intricate parts, jewellery |

| Centrifugal Casting | Spinning a mold to distribute plastic evenly and create hollow, cylindrical parts. | Epoxy, polyester | Pipes, bushings, rollers, pump casings |

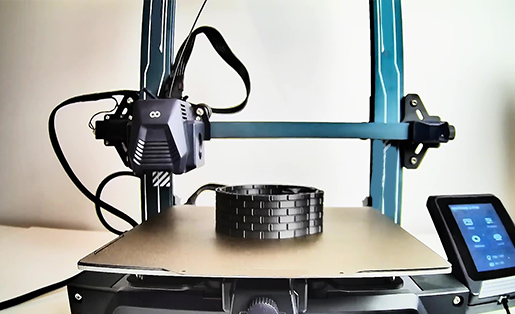

| Fused Deposition Modeling | Extruding thermoplastic filament layer by layer to build a 3D object. | PLA, ABS, PETG, TPU | Prototypes, custom parts, models, tools, functional parts |

| Stereolithography | Using a UV laser to cure liquid resin layer by layer to build high-resolution parts. | Photopolymer resins | Prototypes, dental models, intricate designs, jewellery |

| Selective Laser Sintering | Fusing powder material layer by layer with a laser to produce robust, long-lasting components. | Nylon, TPU | Functional prototypes, complex parts, end-use components |

Table: Plastic Fabrication Methods with its working principles

Process of plastic fabrication

Design and Prototyping:

Using CAD (Computer-Aided Design) software, create a detailed design of the plastic product that takes into account specifications, tolerances, material choices and intended use. Create a product prototype, frequently utilizing techniques like 3D printing, CNC machining or handcrafting, to test the product's functionality and design.

Material Selection:

Based on the needs of the product, choose the right kind of plastic, taking into account aspects like cost, mechanical qualities and resistance to chemicals and heat.

Tooling Preparation:

Prepare the molds or dies required for production processes such as injection molding, extrusion or thermoforming.

Plastic Preparation:

Prepare the plastic material by heating, melting or combining it with additives, depending on the technique.

Fabrication Process:

Shape materials using techniques like CNC machining, thermoforming, injection molding. To get the appropriate shapes and dimensions, keep an eye on the process parameters. For accurate manufacturing, use fixtures and tooling as needed.

Finishing Operations:

Remove any burrs, trim any extra material and carry out surface finishing tasks (such as painting, plating, and sanding). Assemble several manufactured components if required to produce the finished item.

Quality Control:

To make sure the completed parts fulfil requirements, check them for surface flaws, dimensional accuracy and other quality factors.

Packaging and Shipping:

Securely package the completed goods to keep them safe in transit. Deliver the goods to their final location, be it assembly plants or customers.Pros and Cons of Plastic Fabrication

Pros

1. Securely package the completed goods to keep them safe in transit. Deliver the goods

to their final location, be it assembly plants or customers.

2. Since they are usually lightweight, plastics are perfect for applications where

weight is a concern and lower transportation costs.

3. The lifespan of manufactured goods is increased by the high durability and resistance

of many plastics to UV light, chemicals, moisture and corrosion.

4. Particularly for large-scale manufacturing, plastic fabrication techniques frequently

lead to reduced production costs.

5. Excellent design flexibility is provided by plastics, enabling the development of

intricate details, complex geometries and personalized features.

6. Some plastics are ideal for electronics, construction and insulation because of

their superior thermal and electrical insulation qualities.

7. Numerous plastics are recyclable and reusable, supporting efforts to preserve

resources and maintain a sustainable environment.

Cons:

1. Both plastic fabrication processes and the disposal of plastic waste can have negative

environmental consequences.

2.Most plastics are non-biodegradable, leading to long-term accumulation in landfills

and ecosystems.

3. Some plastics contain hazardous chemicals that may pose health risks to humans and

the environment.

4. Certain plastics can degrade or become brittle when exposed to high temperatures or

prolonged UV radiation.

5. Some plastics have poor heat resistance properties, restricting their use in

high-temperature applications.

6. Choosing the right plastic material for a specific application can be challenging due

to the wide variety of options available.

7. Compliance with regulations and standards related to plastic fabrication can be

complex and require additional resources.

Applications of Plastic Fabrication

These represent only a few of the wide range of industries in which plastic fabrication finds use. Because of their cost-effectiveness, durability and versatility, plastics are essential components of contemporary manufacturing processes.

Packaging:

Plastic fabrication is versatile, lightweight and durable, it is widely used in packaging for consumer goods, food, beverages and cosmetics.Automotive parts like dashboards, exterior panels, interior trim and bumpers are made of plastic to increase design flexibility, decrease weight and improve fuel economy.

Construction Materials:

Since plastic fabrication is long-lasting, corrosion-resistant and simple to install, it is used to create construction materials like pipes, fittings, insulation, roofing materials and cladding.

Electronics and Electrical Components:

Plastic offer electrical insulation qualities and adaptability in design, plastics are utilized in electronics and electrical components like casings, connectors, housings and insulation.

Medical Devices and Equipment:

As plastic fabrication is biocompatible and sterilizable, it is used to make medical equipment and devices like syringes, catheters, prosthetics and pharmaceutical product packaging.Because of their adaptability, affordability and visual appeal, plastics are used in the manufacturing of consumer goods like toys, appliances, furniture, sporting goods and kitchenware.

As plastic fabrication is lightweight, it has a high strength-to-weight ratio and is resistant to fatigue and corrosion, it is used to make aerospace components like interior panels, ducting, cabinets and structural elements.

Agricultural Applications:

Due to their affordability, durability and resistance to UV rays, plastics are utilized in agricultural applications such as storage tanks, mulch films, irrigation systems and greenhouse films.

Industrial Equipment:

Since plastic fabrication is easy to customize and resistant to corrosion and chemicals, it is used to make industrial equipment like tanks, containers, machinery parts and conveyor systems.

Recreational Products:

As plastics are lightweight, buoyant and weather resistant, they are used in recreational products like kayaks, surfboards, camping equipment and outdoor furniture.Conclusion

Plastic fabrication stands out as a flexible and cost-effective solution for producing a wide array of products across various industries. Whether it's creating components for electronics, durable parts for automotive applications or lightweight packaging solutions, plastic fabrication techniques offer numerous advantages.

By understanding the different fabrication methods—such as injection molding, extrusion, thermoforming and CNC machining—businesses can select the most suitable process to meet their specific needs. Each method brings its unique strengths, whether it's rapid production, design flexibility or material efficiency.

As industries continue to evolve, the demand for customized, efficient and sustainable solutions grows. Plastic fabrication is poised to meet these challenges, offering innovative approaches to manufacturing that align with modern requirements.

If you're considering plastic fabrication for your next project, it's essential to evaluate your specific needs and consult with experienced professionals to determine the best approach. With the right strategy, plastic fabrication can be a key driver in achieving your production goals.