Introduction

CNC tube bending uses computer controlled machines to bend tubes. Here's the benefits and applications.

Summary

- CNC tube bending is more precise and accurate, less material waste and high quality components across industries.

- Automation and robotics in CNC tube bending increases efficiency, faster production rates and consistent results.

- Key components like CNC control unit, bend dies and monitoring systems are important to optimize the bending process and get repeatable results.

What is CNC Tube Bending?

CNC tube bending means shaping tubes with computer controlled machines to get highly precise bends. This

advanced technique uses automated moving parts driven by electric motors or hydraulic systems to get

accurate and consistent bending. Unlike manual bending tools, CNC tube bending can create complex bends

that can't be done manually, it's a game changer in manufacturing. And being able to bend tube with

precision makes the process more efficient, that's why the tube bender is a must have tool in modern

fabrication.

CNC tube bending makes precise bends and maintains structural integrity by controlling the tube exactly to spec. It makes the tube shape you want while preserving the material strength and quality.

The power of CNC tube bending is in minimizing material waste while maintaining high precision on complex shapes and geometries. Automation in CNC technology means accuracy, less errors and meets industry standards. Automation ensures each bend is to spec, so overall product quality is better.

CNC tube bending combines the precision of computer numerical control with the strength of mechanical bending machines, so it's a smooth and efficient process. This is how you get components with intricate designs and tight tolerances, for industries from automotive to aerospace.

CNC tube bending makes precise bends and maintains structural integrity by controlling the tube exactly to spec. It makes the tube shape you want while preserving the material strength and quality.

The power of CNC tube bending is in minimizing material waste while maintaining high precision on complex shapes and geometries. Automation in CNC technology means accuracy, less errors and meets industry standards. Automation ensures each bend is to spec, so overall product quality is better.

CNC tube bending combines the precision of computer numerical control with the strength of mechanical bending machines, so it's a smooth and efficient process. This is how you get components with intricate designs and tight tolerances, for industries from automotive to aerospace.

Advantages of CNC Tube Bending

The benefits of CNC tube bending are many and it's an essential tool in today's manufacturing. One of

the main benefits is the precision and accuracy it offers, tighter tolerances and precise control

through CNC technology. This is key to making high quality components. Each bend with CNC is to exact

spec, minimising errors and material waste.

In addition to precision, CNC tube bending is faster and more productive. Automating the bending process means faster production rates and complex shapes in one operation, saving time and cost. Plus CNC ensures consistency and repeatability, so you get the same results every time and high quality standards.

Modern software allows for 3D simulation of the bending process. This helps optimize the bending sequence and minimize errors so each bend meets quality standards. Recent advancements are focused on making the machine more precise and reduce waste so CNC tube bending is a reliable way to make complex bends with minimal errors.

The consistency of CNC is ideal for large runs. By producing uniform results across multiple bends CNC machines reduce the variability of manual bending. This is a big advantage in industries that require high precision and quality in their products.

In addition to precision, CNC tube bending is faster and more productive. Automating the bending process means faster production rates and complex shapes in one operation, saving time and cost. Plus CNC ensures consistency and repeatability, so you get the same results every time and high quality standards.

Precision and Accuracy

CNC tube bending is 0.005 to 0.010 inches precise so each bend is to spec. This is made possible by the CNC machines which hold spec across all pieces. The technology reduces the variations and inconsistencies of traditional bending methods for a smooth and precise finish.Modern software allows for 3D simulation of the bending process. This helps optimize the bending sequence and minimize errors so each bend meets quality standards. Recent advancements are focused on making the machine more precise and reduce waste so CNC tube bending is a reliable way to make complex bends with minimal errors.

Efficiency and Productivity

Integrating robotics in CNC tube bending improves production by:- Automating repetitive tasks and reducing human error

- Increasing productivity through automated workflows

- Ensuring consistency across large runs

- Faster production rates

- Creating complex bends quickly and efficiently

Consistency and Repeatability

CNC machines produce consistent results which is key for high volume production and uniform tube bends. Consistency is achieved by ensuring each bend is to spec, eliminating the uncertainty of manual bending. CNC ensures each part is identical which is critical for quality in mass production.The consistency of CNC is ideal for large runs. By producing uniform results across multiple bends CNC machines reduce the variability of manual bending. This is a big advantage in industries that require high precision and quality in their products.

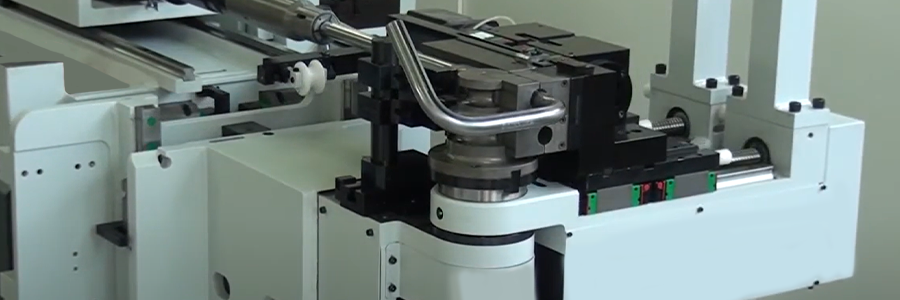

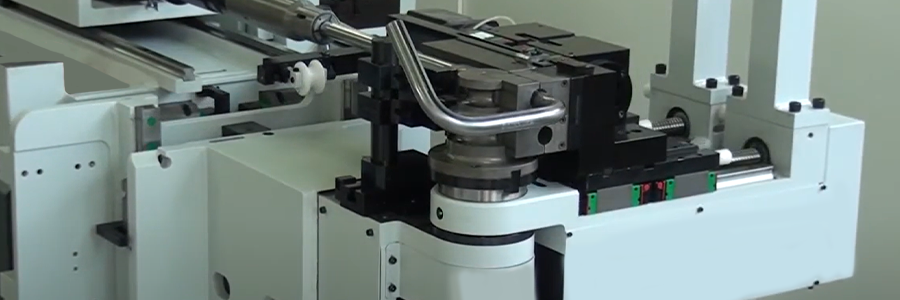

Key Components of CNC Tube Bending Machines

CNC tube bending machines are made up of several key parts that work together to get the bending done.

These parts are the CNC control unit, bend die and mandrel and pressure die and clamp die. Each of

these parts plays a big role in the accuracy and quality of the bending process.

The CNC control unit programs the bending sequence so each bend is precise. The bend die and mandrel get the specific bend radius and prevent tube collapse. The pressure die and clamp die keep the tube shape and precision during the bending process.

Together these parts make CNC tube bending machines produce complex shapes and custom parts with minimal material waste. Some CNC tube bending machines are right handed or left handed and some models can do both for more versatility.

Clamp dies hold the tube in place during bending to get precision and stability. Clamp dies stabilise the tube for uniform bends to meet the dimensions. Together pressure and clamp dies get you consistent and accurate results, that's why they are part of CNC tube bending machines.

The CNC control unit programs the bending sequence so each bend is precise. The bend die and mandrel get the specific bend radius and prevent tube collapse. The pressure die and clamp die keep the tube shape and precision during the bending process.

Together these parts make CNC tube bending machines produce complex shapes and custom parts with minimal material waste. Some CNC tube bending machines are right handed or left handed and some models can do both for more versatility.

Bend Die and Mandrel

Bend dies and mandrels are the heart of the bending process, they do the following:- Bend dies ensure precision in achieving specific bend radii and prevent tube collapse during bending.

- Mandrels are used inside the bending die to maintain the internal shape and structure of the tube, prevent deformation.

- For thin-wall tubes, wiper dies are used to prevent ripples from forming, for smooth finish.

Pressure Die and Clamp Die

Pressure dies push the pipe to maintain its shape and prevent deformation during bending. Consistent high pressure from these dies keeps the tube in shape and prevents collapse during bending. This is important for precise bends which are critical for good results. The pressure is applied effectively to get the best results.Clamp dies hold the tube in place during bending to get precision and stability. Clamp dies stabilise the tube for uniform bends to meet the dimensions. Together pressure and clamp dies get you consistent and accurate results, that's why they are part of CNC tube bending machines.

Bending Machine Considerations

Choosing the right tube bending machine is key to getting the precise, high quality bends you need for

your application. It starts with understanding the type of bending process required—rotary draw bending

for tight radii and complex shapes, mandrel tube bending for maintaining wall integrity or compression

bending for fast and cost effective production. Each has its own advantages depending on the bend

radius, bend angle and tube geometry.

Key factors to consider are tube diameter, wall thickness and material properties. For example thicker materials or larger diameters may require more robust machines with more force, while thinner tubes or smaller radii may need specialized mandrel support to prevent collapse. The tolerances and the final application—exhaust systems or intricate structural components—also come into play.

By considering these variables manufacturers can ensure their bending machines are capable of handling their specific projects and get consistent, precise bends and optimal product quality. Investing in the right machine not only increases productivity but also ensures every bend meets the highest standards regardless of complexity or material.

Key factors to consider are tube diameter, wall thickness and material properties. For example thicker materials or larger diameters may require more robust machines with more force, while thinner tubes or smaller radii may need specialized mandrel support to prevent collapse. The tolerances and the final application—exhaust systems or intricate structural components—also come into play.

By considering these variables manufacturers can ensure their bending machines are capable of handling their specific projects and get consistent, precise bends and optimal product quality. Investing in the right machine not only increases productivity but also ensures every bend meets the highest standards regardless of complexity or material.

Custom Bending Solutions

For manufacturers with unique design challenges or non-standard tube shapes, custom bending is the way

to go. Working with a specialist tube bending service provider allows you to develop a bespoke bending

process to meet your specific requirements whether it's high pressure, unusual tube sizes or complex

shapes.

The process starts with a thorough analysis of the tube size, material, wall thickness and bend radius. Based on these parameters the provider will recommend the best bending method – freeform bending for intricate variable radius shapes or rotary draw bending for precise repeatable curves. Tolerances and quality standards are paramount to ensure even the most demanding specifications are met.

Custom bending is particularly useful in industries like aerospace and automotive where high pressure tubing and complex geometries are common. By using advanced bending machines and expert engineering you can create shapes and forms that standard equipment can't and still meet the highest quality and performance.

The process starts with a thorough analysis of the tube size, material, wall thickness and bend radius. Based on these parameters the provider will recommend the best bending method – freeform bending for intricate variable radius shapes or rotary draw bending for precise repeatable curves. Tolerances and quality standards are paramount to ensure even the most demanding specifications are met.

Custom bending is particularly useful in industries like aerospace and automotive where high pressure tubing and complex geometries are common. By using advanced bending machines and expert engineering you can create shapes and forms that standard equipment can't and still meet the highest quality and performance.

Design and Engineering in CNC Tube Bending

The design and engineering phase is key to any CNC tube bending project. This involves planning and

defining key parameters; tube material, diameter, wall thickness, bend radius and bend angle. By

defining these parameters engineers can ensure each bend meets the tolerance and the shape intended.

Laser cutting is often integrated into the process to create complex shapes and precise holes before the bending starts. CNC tube bending machines are better at tighter tolerances and more intricate bends making them perfect for applications where quality and accuracy is critical – medical equipment, aerospace components and high performance automotive parts.

By investing in the latest bending machines and engineering expertise manufacturers can reduce production time, material waste and increase productivity. The end result is a product that meets and often exceeds industry standards for quality and precision.

Laser cutting is often integrated into the process to create complex shapes and precise holes before the bending starts. CNC tube bending machines are better at tighter tolerances and more intricate bends making them perfect for applications where quality and accuracy is critical – medical equipment, aerospace components and high performance automotive parts.

By investing in the latest bending machines and engineering expertise manufacturers can reduce production time, material waste and increase productivity. The end result is a product that meets and often exceeds industry standards for quality and precision.

Quality Control in CNC Tube Bending

To get the best out of CNC tube bending you need a quality control strategy throughout the whole bending

process. This starts with regular inspection and maintenance of the bending machine and tooling to

ensure consistency. Advanced technologies like laser cutting and CNC machining are used to get the

accuracy and repeatability of each bend.

Quality control measures include weld inspections, dimensional checks and material testing to ensure each tube meets the tolerance and structural requirements. By doing this manufacturers can reduce defects, waste and deliver products that meet or exceed market expectations.

This is especially important in industries like automotive, aerospace and medical equipment where the tube bending is non negotiable. By controlling quality manufacturers not only protect their reputation but also their long term competitiveness in a tough market.

Quality control measures include weld inspections, dimensional checks and material testing to ensure each tube meets the tolerance and structural requirements. By doing this manufacturers can reduce defects, waste and deliver products that meet or exceed market expectations.

This is especially important in industries like automotive, aerospace and medical equipment where the tube bending is non negotiable. By controlling quality manufacturers not only protect their reputation but also their long term competitiveness in a tough market.

Common Applications of CNC Tube Bending

CNC tube bending is used across many industries because it can create precise and complex shapes to meet

specific design requirements. Automotive, aerospace and furniture industries use CNC tube bending to

make parts with intricate designs and tight tolerances. Many manufacturers offer a full range of CNC

tube bending services to meet the diverse needs of automotive, aerospace and furniture industries. These

applications not only add functionality and style to the products but also quality and performance.

Automotive industry uses CNC tube bending to make exhaust systems and roll cages, aerospace uses it to form shapes for aircraft and spacecraft structures. Furniture industry uses CNC tube bending to make stylish and functional frames that add both style and structural integrity.

For example CNC tube bending is used to produce exhaust systems that require high precision and durability. Roll cages which are critical for occupant safety are manufactured using CNC tube bending to achieve the necessary strength and structural integrity.

CNC tube bending allows for the creation of tubing designs that are lightweight and durable which is critical for aircraft and spacecraft components. This technology helps aerospace manufacturers create complex shapes that improve product performance and safety.

For example CNC tube bending is used to make ergonomic chair frames that are comfortable and supportive. Decorative furniture pieces benefit from the precision and flexibility of CNC tube bending to create unique and beautiful designs.

Automotive industry uses CNC tube bending to make exhaust systems and roll cages, aerospace uses it to form shapes for aircraft and spacecraft structures. Furniture industry uses CNC tube bending to make stylish and functional frames that add both style and structural integrity.

Automotive Industry

In the automotive industry CNC tube bending is used to produce exhaust systems, roll cages and various structural components for safety and performance. The precision and accuracy of CNC tube bending is key to meeting the quality standards in the automotive industry. This allows manufacturers to create complex shapes that can be welded together.For example CNC tube bending is used to produce exhaust systems that require high precision and durability. Roll cages which are critical for occupant safety are manufactured using CNC tube bending to achieve the necessary strength and structural integrity.

Aerospace Sector

The aerospace industry uses CNC tube bending to form the intricate shapes required for aircraft and spacecraft structures. This technology is critical in the aerospace sector by allowing the fabrication of complex geometries to optimise weight and aerodynamics. The precision and accuracy of CNC tube bending is key to meeting the quality standards in aerospace applications.CNC tube bending allows for the creation of tubing designs that are lightweight and durable which is critical for aircraft and spacecraft components. This technology helps aerospace manufacturers create complex shapes that improve product performance and safety.

Furniture and Fixtures

In the furniture industry, CNC tube bending is used to make stylish and functional frames, to create unique designs and ergonomic features. This allows for intricate frames and decorations that add to the aesthetics and structural integrity. With CNC tube bending furniture manufacturers can produce parts to high quality and design standards.For example CNC tube bending is used to make ergonomic chair frames that are comfortable and supportive. Decorative furniture pieces benefit from the precision and flexibility of CNC tube bending to create unique and beautiful designs.

Factors Affecting CNC Tube Bending Quality

Several things affect the quality of CNC tube bending, material type and wall thickness, tube diameter

and bend radius and tolerances and specs. Knowing these is key to getting high quality bends that meet

industry standards. By considering these you can optimize the bending process and get consistent and

accurate results.

Material type and wall thickness affect the bending process by the spring back and the likelihood of wrinkling or collapsing. The relationship between tube diameter and bend radius is critical for successful bending, tighter bend radii puts more stress on the tube material. Following specs is key to getting the quality of bends to meet industry standards.

Material thickness can also cause spring back variations; thinner materials will spring back more than thicker ones. Thin wall tubes require precise tooling to avoid wrinkling or collapsing during the bending process. Choosing the right material and wall thickness will get you the best results.

For example using a tighter radius on a bigger diameter tube can cause excessive stretching and tube material failure. Knowing the relationship between these helps manufacturers to optimise the bending process and produce bends to industry standards.

Industry standard for bend angle in CNC tube bending is 1 degree and for ovality is 8% to 4%. These specs ensure the bends are precise and uniform which is critical for applications that require high accuracy and consistency. Following these specs ensures components meet the strict quality standards of various industries.

Material type and wall thickness affect the bending process by the spring back and the likelihood of wrinkling or collapsing. The relationship between tube diameter and bend radius is critical for successful bending, tighter bend radii puts more stress on the tube material. Following specs is key to getting the quality of bends to meet industry standards.

Material Type and Wall Thickness

Different materials have different spring back properties which can affect the bending process. For example stainless steel or titanium has more spring back than copper because of their hardness. So the bending process has to account for these variations to get the desired bend angles and precision.Material thickness can also cause spring back variations; thinner materials will spring back more than thicker ones. Thin wall tubes require precise tooling to avoid wrinkling or collapsing during the bending process. Choosing the right material and wall thickness will get you the best results.

Tube Diameter and Bend Radius

Tube diameter to bend radius is key to successful bending. Tighter radii or smaller angles can put more stress on the tube material and cause elongation or cracking. So you need to calculate and select the right bend radius for each tube diameter to ensure the bends are sound and good quality.For example using a tighter radius on a bigger diameter tube can cause excessive stretching and tube material failure. Knowing the relationship between these helps manufacturers to optimise the bending process and produce bends to industry standards.

Tolerances and Specifications

Following specifications is key to meeting industry standards for bends. Precision tooling (mandrels and wiper dies) is important for consistent results in mandrel tube bending. By holding tighter tolerances you can get high quality bends that meet the exact specs for each application.Industry standard for bend angle in CNC tube bending is 1 degree and for ovality is 8% to 4%. These specs ensure the bends are precise and uniform which is critical for applications that require high accuracy and consistency. Following these specs ensures components meet the strict quality standards of various industries.

CNC Tube Bending Processes

CNC tube bending has many processes, each with its own advantages and applications. These processes

include rotary draw bending, compression bending and freeform bending. Knowing the differences between

these will help manufacturers choose the right process for their needs.

Some CNC tube bending processes like roll bending can create complex shapes and precise radii without having to cut or pre-form the tube first.

Rotary Draw bending is good for tight radii and is used in applications that require high precision. Compression bending is fast and cost effective when roundness is not critical. Freeform bending has unlimited design flexibility and can create complex shapes without having to have intermediate straight sections.

The production rate for the One Pass Acrotech method of rotary draw bending can range from 100 to 350 parts per hour, depending on the machine setup. This method is ideal for applications requiring high precision and intricate bends, making it a preferred choice for industries such as automotive and aerospace.

Compression bending is applying force to the tube, pushing it into a bend die to get the desired shape. This is for when speed and cost is more important, so it's popular for mass production of simpler bends.

This offers design flexibility. Freeform bending doesn't require any straight sections between bends, so more design flexibility, like custom radius bends. This is perfect for applications that need complex shapes and intricate designs, so great for furniture manufacturing and custom fabrication.

Some CNC tube bending processes like roll bending can create complex shapes and precise radii without having to cut or pre-form the tube first.

Rotary Draw bending is good for tight radii and is used in applications that require high precision. Compression bending is fast and cost effective when roundness is not critical. Freeform bending has unlimited design flexibility and can create complex shapes without having to have intermediate straight sections.

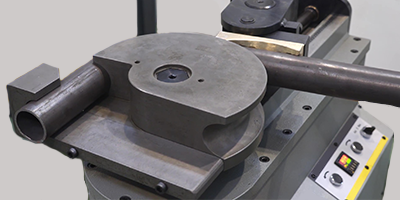

Rotary Draw Bending

Rotary draw bending is particularly effective for producing bends that are three to four times the centerline radius of the tube diameter. This process involves:- Using a bend die

- Using a clamp die

- Using a pressure die - These tools help achieve precise bends. The tightest achievable centerline radius for tube bending with rotary draw bending is one times the tube diameter, which helps minimize wall thinning using tools like a mandrel.

The production rate for the One Pass Acrotech method of rotary draw bending can range from 100 to 350 parts per hour, depending on the machine setup. This method is ideal for applications requiring high precision and intricate bends, making it a preferred choice for industries such as automotive and aerospace.

Compression Bending

Compression bending is for when speed and cost is more important. Key points:- May not be perfect tube roundness.

- Chosen when speed and cost is more important than roundness.

- For 1" tube, centerline radius must be at least 2".

Compression bending is applying force to the tube, pushing it into a bend die to get the desired shape. This is for when speed and cost is more important, so it's popular for mass production of simpler bends.

Freeform Bending

CNC freeform bending:- Bends of any radius without intermediate straight sections.

- One tooling only: a ceramic ring for the tube size being used.

- Computer controlled process that moves the ceramic ring to achieve precise bends.

This offers design flexibility. Freeform bending doesn't require any straight sections between bends, so more design flexibility, like custom radius bends. This is perfect for applications that need complex shapes and intricate designs, so great for furniture manufacturing and custom fabrication.

Innovations in CNC Tube Bending Technology

Recent CNC tube bending innovations have improved precision, speed and capabilities of bending machines. These include software integration, real time monitoring and adjustment and automation and robotics. These have made the bending process more efficient and capable of making complex shapes with high precision.

These innovations allow manufacturers to optimise production, reduce waste and achieve higher quality and consistency. Software and automation has turned CNC tube bending into a very efficient and precise manufacturing process.

Advanced Software Integration

The CNC control unit utilizes a Windows-based operating system along with custom software for managing bending parameters. Key features of the CNC control unit include 3D workpiece simulation and the ability to perform single-step operational simulations. These advanced software capabilities enhance the precision and efficiency of CNC tube bending machines, enabling more accurate and consistent operations.Advanced software integration allows manufacturers to optimize the bending process, reduce errors and achieve greater precision. These software solutions allow for better programming and execution of complicated bending sequences, making CNC tube bending a more reliable and efficient manufacturing technique.

Real-Time Monitoring and Adjustments

Real time monitoring allows for continuous checking of the bend process, so any errors are detected in real time. Real time monitoring systems reduce downtime and waste. On the fly adjustments based on real time data allow the operator to correct the bend before the part is complete.In the end real time monitoring and on the fly adjustments means better bend quality and consistency in production. This means manufacturers can get reliable and accurate results so every bend meets spec.

Automation and Robotics

CNC tube bending has many benefits:- Automates complex bending operations for high speed.

- Roboticizes multiple bends at once for more productivity.

- Advanced software integration for better programming and execution of complex bending sequences.

Real time monitoring allows for adjustments on the fly during the bending process for high quality and less waste. By automating and roboticizing CNC tube bending machines you get more efficiency and precision, it's a must have in modern manufacturing.

Conclusion

In short CNC tube bending is a game changer in precision manufacturing. With automation, precision

tooling and real time monitoring CNC tube bending machines can produce complex shapes with high accuracy

and consistency. It's used across automotive, aerospace and furniture industries to produce components

to tight tolerances.

The advancements in CNC tube bending technology like software integration and automation and robotics have made these machines even more efficient and capable. So CNC tube bending is a must have for manufacturers looking to improve their processes and get higher quality and consistency. With these advancements the future of CNC tube bending looks good and will open up even more possibilities for more complex and efficient manufacturing.

The advancements in CNC tube bending technology like software integration and automation and robotics have made these machines even more efficient and capable. So CNC tube bending is a must have for manufacturers looking to improve their processes and get higher quality and consistency. With these advancements the future of CNC tube bending looks good and will open up even more possibilities for more complex and efficient manufacturing.