Introduction

5 axis CNC machining allows for complex and precise parts in one set up. This is critical for industries

like aerospace and medical devices where accuracy and speed is key.

Key Takeaways

- 5 axis CNC machining allows for complex parts with more precision and less production time by machining multiple faces at once without repositioning.

- There are 3 types of 5 axis machines, each with its own advantages for stability, precision and flexibility.

- High cost and complex programming but long term benefits in efficiency and quality makes 5 axis CNC machining a worthwhile investment for precision manufacturing.

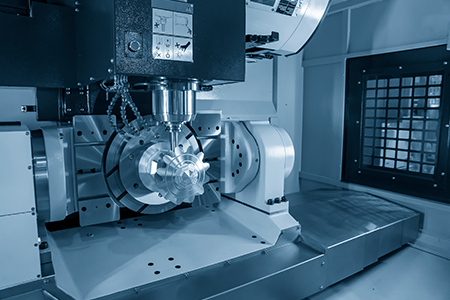

Understanding 5 Axis CNC Machining

5 axis CNC machining is an advanced machining process that uses cutting tools on 5 different axes to

create parts with complex shapes and sizes. These 5 axes are:

Compared to 3 axis machining, 5 axis CNC machining can move the workpiece in more dimensions without removing it, reducing production time and overall accuracy. In a direct comparison 5 axis machining is better and more flexible in complex geometries than 3 axis systems. That's why it's a must have in industries that require high precision and complex geometries.

- X-axis

- Y-axis

- Z-axis

- A-axis

- B-axis

Compared to 3 axis machining, 5 axis CNC machining can move the workpiece in more dimensions without removing it, reducing production time and overall accuracy. In a direct comparison 5 axis machining is better and more flexible in complex geometries than 3 axis systems. That's why it's a must have in industries that require high precision and complex geometries.

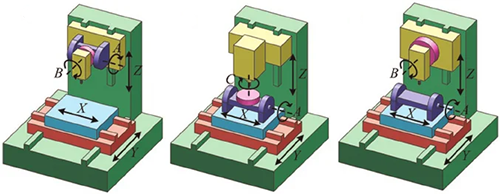

Types of 5 Axis CNC Machines

When it comes to 5-axis CNC machines there are three types:

- Head/Head: Both rotational axes are in the spindle head so you can machine big parts without structural instability. This is good for high precision and stability applications.

- Head/Table: has one rotational axis in the head and one in the rotary table so it's good for big and heavy parts and human stability. It also provides clear direction to rotate for optimal setup on linear axes which is a sign of efficiency.

- Table/Table: has two rotational axes in the table itself so it's good for complex machining tasks. These different configurations means there's a 5-axis CNC machine for every application, each with its own benefits for precision, stability and versatility.

Key Advantages of 5 Axis CNC Machining

More Precise and Accurate

One of the best things about 5 axis CNC machining is it's more precise for complex parts than traditional methods. The extra rotary axes allows the machine to attack complex angles and create intricate geometries with more accuracy. This is especially good for industries that require high precision like aerospace and medical device manufacturing.High speed milling tools in 5 axis machining gives better surface finish. Reduced vibration during cutting makes for smoother transitions and more consistent cutting, parts that meet and exceed quality standards. This level of precision and accuracy is what 5 axis CNC machines are capable of.

Faster Production Times

In manufacturing time is money. 5-axis CNC machining has many benefits:- It allows you to machine 5 sides of a part in one operation, saving time and reducing cost.

- It reduces cycle times, so you can make parts faster and more efficiently.

- The 5-axis machine design allows for faster material removal, which reduces cycle times.

For shop owners and manufacturers that means more productivity, more work and faster delivery of high quality parts to customers. The tangential tool arrangement in 5-axis CNC machining removes more material per rotation, so it's not only faster but also more cost effective in the shop while optimizing spindle speed.

Reduced Need for Multiple Setups

One of the big benefits of 5 axis machining is reduced set ups. Traditional machining requires repositioning the part multiple times to get the shape you want, which increases the chance of errors and extends production time. 5 axis machining can do all the milling operations for complex geometries in one setup, so you eliminate those issues.Doing multiple milling operations in one operation, 5 axis machining saves time and accuracy. Reduced set ups makes the process more cost effective and efficient so you can focus on making good parts without the hassle of multiple set ups.

Surface Finish and Drilling Capabilities

5-axis CNC machining has the best surface finish and drilling capabilities. Minimizing vibration during

cutting means better surface quality and more consistent cutting overall.

Plus the A-axis and B-axis on a 5-axis machine brings the work material closer to the tool, which means better surface finishes. This means better part performance and less secondary processing which means cost savings for you.

This means better drilling and better end products. The tangential tool arrangement in 5-axis CNC machining allows for more material removal per tool rotation, so you get faster production. This is what makes 5-axis CNC capable of handling complex parts with ease and precision.

Better Surface Finishes

Better surface finishes are a 5-axis CNC machining hallmark. Shorter tools mean less vibration and better surface quality. Continuous tool movement means smoother transitions and better surface finishes which are critical for both the aesthetic and functional performance of precision parts.Plus the A-axis and B-axis on a 5-axis machine brings the work material closer to the tool, which means better surface finishes. This means better part performance and less secondary processing which means cost savings for you.

Advanced Drilling

5-axis CNC technology gives you:- Tighter angles

- Finer finishes

- Access to complex parts

- Finishes that are perfect for complex components

This means better drilling and better end products. The tangential tool arrangement in 5-axis CNC machining allows for more material removal per tool rotation, so you get faster production. This is what makes 5-axis CNC capable of handling complex parts with ease and precision.

Industries Using 5 Axis CNC Machining

Medical device manufacturing uses 5 axis CNC machining to create complex implants and surgical tools with intricate shapes. Automotive uses 5 axis for high performance engines and prototyping custom parts, efficiency and innovation.

Energy industry uses 5 axis CNC machining for turbine parts and complex piping systems, energy production. The demand for high precision parts in aerospace and medical is driving 5 axis machining centers. Swivel head machines are useful in aerospace for large parts without vibration, precise cuts. These are just a few examples of the many industries that use 5 axis CNC machining.

Challenges and Considerations

While 5-axis CNC machining has many benefits, there are also challenges and considerations. The high

cost and complex programming can be a barrier for some manufacturers.

Although the cost is high the long term gains in efficiency and product quality make it worth it. Manufacturers who invest in 5-axis CNC will see big returns in productivity and precision.

The complexity of programming a 5-axis CNC machine means operators need to have advanced knowledge to get the tool paths right and avoid errors. Investing in advanced CAM software and skilled personnel is key to getting the most out of this technology.

High Cost

The high upfront cost of 5-axis CNC machines can be a barrier for some businesses. This includes the cost of the machines, software and tools and the need for skilled operators to use the technology. But this investment is often justified by the precision, speed and reduced set up's 5-axis machining offers.Although the cost is high the long term gains in efficiency and product quality make it worth it. Manufacturers who invest in 5-axis CNC will see big returns in productivity and precision.

Complex Programming

Programming 5-axis CNC machines is more complex than 3-axis systems, requires advanced software and a good understanding of machining. This complexity requires specialized training and expertise to operate effectively and avoid costly mistakes.The complexity of programming a 5-axis CNC machine means operators need to have advanced knowledge to get the tool paths right and avoid errors. Investing in advanced CAM software and skilled personnel is key to getting the most out of this technology.

Future Trends in 5 Axis CNC Machining

- Streamlines the process

- Reduces errors

- Allows real time adjustments

- Optimizes cutting conditions and efficiency.

Conclusion

In conclusion 5 axis CNC machining has many benefits, precision, faster production times and less setup.

It's a must have in industries that require high precision and complex geometry. But it has its

challenges, high initial cost and complex programming.

Despite the challenges the future of 5 axis CNC machining looks good, several trends will make it even better. Manufacturers that invest in this technology will see big returns in productivity and precision. By embracing 5 axis CNC machining businesses will be ahead of the curve and meet the growing demand for high precision parts.

Despite the challenges the future of 5 axis CNC machining looks good, several trends will make it even better. Manufacturers that invest in this technology will see big returns in productivity and precision. By embracing 5 axis CNC machining businesses will be ahead of the curve and meet the growing demand for high precision parts.