Introduction

If you're looking to understand how Urethane CAS casting works, you've come to the right place. Urethane CAS casting uses silicone molds to create precise plastic parts, making it an economical alternative and an efficient choice for short-run productions and prototypes. This guide covers everything from the materials and methods involved to the benefits and applications of Urethane CAS casting.

Key Takeaways

- Urethane casting is an economical method for producing high-quality prototypes and low to medium volume production, utilizing silicone molds for complex parts.

- The urethane casting process is efficient, involving the creation of a master model, silicone mold fabrication and precise resin mixing, allowing for rapid production cycles.

- Material selection in urethane casting is critical, considering properties such as hardness, color and abrasion resistance to meet specific application requirements.

Understanding Urethane Casting

Urethane casting has minimal processing requirements as it doesn't require high heat or pressure. This makes it suitable for rapid prototyping and low volume production. The typical production volume for urethane casting is 10 to 200 units, so it's ideal for low volume to medium volume production. This versatility has many advantages:

- Designers can make high quality parts without the high cost and long lead times of other manufacturing methods.

- It's cost effective.

- Can make parts with almost unlimited complexity.

- Can include intricate details and designs without uniform wall thickness.

Plus urethane casting is a bridge production method that allows for a smooth transition from prototype development to low volume production. This is especially useful in industries where quick iterations and modifications are required to meet market demands. A case study showed a customer chose urethane casting over injection molding for its flexibility and cost effectiveness in making complex geometries.

The Urethane Casting Process

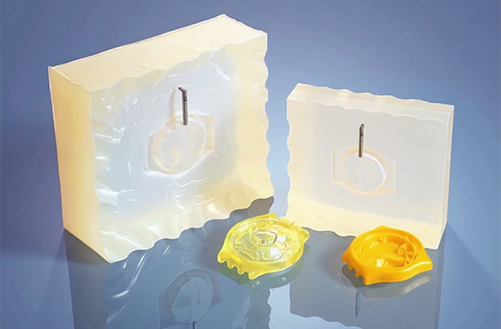

Once the master model is ready a silicone mold is created, a negative impression of the master model. The mold cavity is formed by this negative impression and its design affects the quality and surface detail of the final part. During mold making the master part is glued, styrene blocks and modeling clay to keep it in place. Vent straws and a pouring funnel are used for the process. They help direct the urethane resin into the mold crevices. Liquid silicone is used when making molds as it can capture fine details from the master model.

Next step:

- Mix the urethane resin in the correct ratio with a curing agent to get consistent material properties.

- Degassing the mix in a vacuum chamber to get rid of any air before pouring.

- Pour the urethane mix into the mold under vacuum to get rid of any air bubbles and defects in the final part.

Curing is when the urethane is solidified by putting the filled mold in the oven or letting it sit at room temperature depending on the resin used. Careful demolding is key to preserve the quality of the final part and the silicone mold after curing. Tooling lead times for urethane molds are much shorter, usually 1-2 weeks compared to several weeks for injection molds. This process can produce parts to test design and material choices, so is good for testing in real world applications.

Benefits of Urethane Casting

One of the biggest benefits of urethane casting is the quick turnaround time. This is perfect for rapid prototyping and small batch production so you can get your product to market faster. The molds used in urethane casting can be reused multiple times so you can produce multiple parts at once.

Plus urethane casting is often more cost effective than additive manufacturing when producing a large number of prototypes. Lower tooling costs and flexibility in production adjustments makes urethane casting a fast and cost effective way to produce high detail parts.

Plus urethane casting is often more cost effective than additive manufacturing when producing a large number of prototypes. Lower tooling costs and flexibility in production adjustments makes urethane casting a fast and cost effective way to produce high detail parts.

Common Urethane Casting Materials

Materials and their applications:

- AFP3320: for high heat applications due to its resistance and durability.

- Urethane casting: for medical applications where precise part production is critical for device compatibility.

- Food grade or medical compliant urethane materials: for medical and food applications to ensure safety.

- Urethane materials with optical clarity: for translucent parts in applications where transparency or semi-transparency is required.

- Urethane materials with UV stability: for preventing degradation and discoloration from UV exposure.

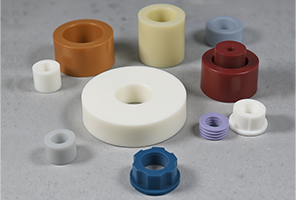

Urethane and silicone parts are used in consumer goods such as household handles, hearing aids and movie props showing their versatility in end use products.

Rigid Urethanes

Rigid urethane castings are characterized by high strength and dimensional stability, making them suitable for structural applications. Urethane casting resins are highly versatile polymers that can replicate the properties of traditional plastics. AFP3200 is commonly used for consumer packaged goods and industrial components due to its robust nature.The hardness rating of AFP3320 urethane is 80 Shore D, making it suitable for high-heat applications. Medium Texture (MT11020 Equivalent) is used for items requiring more texture, typically on hard plastic-like housings for aesthetics or grip.

Heavy texture urethane casting is utilized for creating hard plastic-like housings or cases. This method is ideal when a cosmetic heavy texture is needed for aesthetics or better grip. AFP3100 is comparable to ABS and PC/ABS plastics in terms of performance.

Urethane Elastomers

Urethane elastomers are known for their softness, flexibility and good tear strength, making them suitable for a variety of dynamic applications. E1095AB material is commonly used in applications such as shopping cart wheels, rollers and bumpers due to its durability.E1005AL is an extra soft elastomer suitable for applications like medical training models, special effects and props. E1060AL is a medium-hard elastomer used for components such as bellows and boots, providing a balance of toughness and flexibility.

E1070 AB elastomer is recognized for its excellent durability and resistance to wear, making it a well suited excellent option for applications that involve constant movement.

Silicones

Silicones are commonly used in urethane casting for creating molds for end-use parts. They are also utilized in the casting process for bridge tooling. AFS60 casting silicone can be used for mold-making, gaskets and seals.AFS30 silicone has a hardness classification of 30 Shore A. AFS40 silicone has a hardness scale rating of 40 Shore A. AFS15 silicone is classified with a hardness of 15 Shore A. These hardness classifications indicate the softness and versatility of silicone materials in various applications.

Material Selection Factors

When selecting urethane materials, it is important to consider:

Collaboration with casting experts is vital during material selection to obtain guidance and tailored recommendations based on specific project needs. Conducting material test and prototyping can help verify that the selected urethane material meets the intended requirements. Factors to consider when selecting materials include:

Considering the durometer (hardness) of the urethane should align with specific project requirements and its intended use to ensure performance suitability.

- The desired properties and characteristics of the final parts

- Project requirements

- Budget constraints

- Production volume needs

Collaboration with casting experts is vital during material selection to obtain guidance and tailored recommendations based on specific project needs. Conducting material test and prototyping can help verify that the selected urethane material meets the intended requirements. Factors to consider when selecting materials include:

- Colors

- Textures

- Finishes

- Adherence to design for manufacture best practices.

Considering the durometer (hardness) of the urethane should align with specific project requirements and its intended use to ensure performance suitability.

Hardness (Durometer)

Durometer is the industry standard for measuring the hardness of tough materials. Higher Shore values means a harder material. This is important for determining if urethane materials are suitable for your application.Color and Clarity

Urethane materials can be opaque or translucent. When selecting urethane casting materials, transparency or translucency is key to meeting your project requirements. Branding and visual aesthetics are factors to consider when choosing color for urethane casting materials.Abrasion and Chemical Resistance

Abrasion is important when urethane parts will be in contact with other surfaces. Durability and wear resistance are key characteristics of the E1070 AB material used in urethane applications. Testing abrasion and chemical resistance ensures urethane parts will last in your application.Designing for Urethane Casting

Urethane casting is very flexible so you can make changes based on customer feedback. Same design principles apply to urethane casting as injection molding but it's more forgiving with less shrinkage and sink marks. Uniform wall thickness in urethane casting is key to prevent deformation during cure. Also consider wall thickness for structural integrity and manufacturability, the right wall thickness will make the part perform as intended and producible.

But some design features like overhangs and blind holes are not suitable for urethane casting. Following these design rules will get you high quality urethane cast parts.

But some design features like overhangs and blind holes are not suitable for urethane casting. Following these design rules will get you high quality urethane cast parts.

Wall Thickness and Draft Angles

0.020” or thinner walls can be used for small parts in urethane casting. Draft angle for urethane casting is 3-5 degrees. Uniform wall thickness reduces the chance of deformation in urethane parts.Ribs and Bosses

Ribs are used to strengthen certain areas. They do so without adding thickness. Ribs should be spaced at least 2x their thickness apart to distribute weight evenly. Fillet radius should be at least 1/4 of the rib thickness. This is for reinforcing ribs.Fillets and Inserts

Inserts like threaded inserts can be added to urethane casting molds to make parts functional by allowing them to be screwed in. Metal dowels are inserted into the master part holes during the mold making process. This allows for through holes in the cast parts. Fillets are used in design to reduce stress concentrations which makes urethane cast parts more durable and longer lasting.Finishing Options for Urethane Cast Parts

Urethane cast parts can have many finishes:

Textured can be painted or manual to add grip and hide scuffs, custom can add more personalization beyond standard options. These finishes ensure the final part meets functional requirements and looks good, surface quality, smooth finish and fine details.

- Gloss: shiny or reflective surface, very smooth, for aesthetic applications.

- Matte: smooth surface that doesn't reflect light, minimizes fingerprints, great for high touch areas.

- Textured

- Custom

Textured can be painted or manual to add grip and hide scuffs, custom can add more personalization beyond standard options. These finishes ensure the final part meets functional requirements and looks good, surface quality, smooth finish and fine details.

From Prototype to Production

Urethane casting has proven effective in producing parts that require quick market entry without extensive retooling at a low cost. Key aspects include:

As production scales, transitioning to rapid design molding can help move towards injection molding for larger quantities, up to 10,000 units. The final parts undergo the following processes to achieve production-level quality:

- Typical quantities produced in low-volume production range from 20 to 200 units.

- Ideal for small batch production and rapid prototyping.

- Allows for quick iterations and modifications based on customer feedback.

- Ensures that the final product meets market demands.

As production scales, transitioning to rapid design molding can help move towards injection molding for larger quantities, up to 10,000 units. The final parts undergo the following processes to achieve production-level quality:

- Cured

- Removed from the mold

- Sanded

- Polished

- Painted: This seamless transition from prototype to mass production ensures that products can break efficiently scaled to meet growing demand, including considerations for mold design.

Conclusion

In short, urethane casting is a versatile and cost effective way to make high quality parts with complex geometries. From the master pattern creation to the finish options, the urethane casting process is flexible and fast. Whether for prototyping, small batch or production, urethane casting has the flexibility and precision to bring your ideas to life. Try urethane casting and make your ideas a reality.