Introduction

CNC mandrel bending is a way to bend tubes without damage. It uses a CNC machine to control and a mandrel to support the tube. This article explains how CNC mandrel bending works, the components, benefits and applications.

Summary

- CNC mandrel bending is precise and efficient by automating the process, reducing human error and ensuring consistency in tube and pipe manufacturing.

- The key components of CNC mandrel bending machines such as bend dies, clamp dies and mandrels are important to achieve accurate bends and tube integrity.

- Regular maintenance and new technologies like IoT and AI are important to optimize CNC mandrel bending machines performance and extend their life.

Understanding CNC Mandrel Bending

Mandrel bending is a specialized process to make smooth, accurate bends without compromising strength or quality. It's precise and reliable to bend tube and pipe without damage. At its core:

- Insert a mandrel – a metal bar – inside the tube to provide internal support during the bending process

- Prevent the tube from collapsing

- Ensure the bend is intact

Mandrel bending uses a solid metal rod, called a mandrel, to hold the tube's structure during the bending process, prevent collapse and make precise, damage-free bends.

The integration of CNC technology in mandrel bending has changed the game. CNC mandrel benders allow operators to make complex bends with a single button press, increasing efficiency and reducing human error. This automation not only makes each bend more precise but also ensures consistency across multiple bends which is critical for industries that demand high quality and repeatability. CNC mandrel benders can make high quality mandrel bends for various applications.

Also, CNC mandrel bending is versatile, can handle various materials and bend radii, so it's suitable for many applications. CNC mandrel bending can handle various bend radii, so it's good for small radius bends and large radius bends. Whether you're bending rectangular tubing for automotive parts or making intricate shapes for aerospace structures, the precision and versatility of CNC mandrel bending is a must have in modern manufacturing.

Key Components of a CNC Mandrel Bending Machine

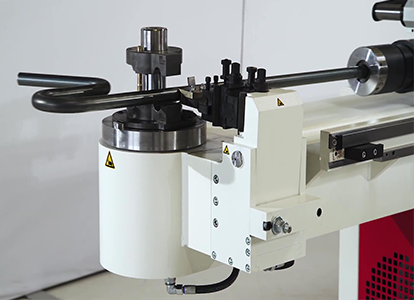

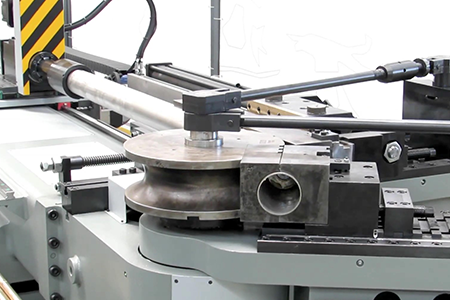

CNC mandrel bending machines are efficient and precise because of several key components, each playing a big part in the bending process. Knowing these components will help you optimize the machine and get the bend you want. The bending head houses the main tooling and controls the movement of the tube during bending.

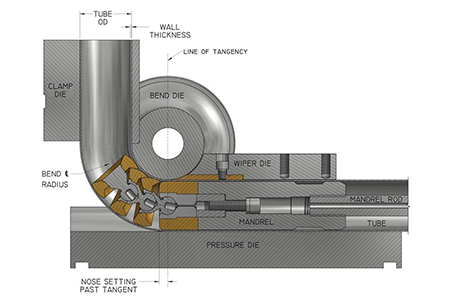

The bend die is one of the most important components—it shapes the tube and sets the bend radius. During the bending process, the bend die rotates, guiding the tube into the desired shape while maintaining pressure to prevent deformities.The clamp die complements the bend die. It holds the tube against the bend die to prevent slippage and ensure precision. The tube bend is key to getting the right angles.The CNC system controls the axis movement and alignment, which is critical to getting consistent and accurate bends.

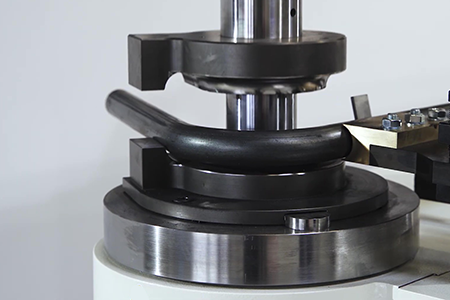

Another important component is the pressure die. It applies the force to press the tube into the bend die to get a good bend without damaging the material.Mandrels inserted into the tube provide internal support to prevent collapse and maintain the tube shape during bending.Wiper dies are also important as they prevent wrinkles on the inner surface of the bend, helping to achieve a cleaner finish.

CNC Mandrel Bending Process

CNC mandrel bending is a series of steps designed to be precise and efficient. The process begins with the tube being cut to the required length and any necessary markings or measurements are made. The tube must be clean and free of defects to ensure a high-quality bend.

The bending process involves:

- The tube is clamped and aligned to the bending machine for proper positioning.

- The mandrel is inserted into the tube and positioned at the tangent point where the bend starts to ensure support.

- As the bend die rotates, the tube is bent to the desired angle using the tube bender.

- The CNC machine controls the distance the tube travels during the bend to get accurate and repeatable bends.

- The outside of the tube stretches and the inside radius compresses, this affects the final shape of the bend. Bending tubing is critical to get precise results.

Once bent, the mandrel can be removed during the last degrees or after the bend to keep the shape. Regular calibration and inspection ensures accuracy and consistency throughout the bending process, as per best practices.

Pressure Die System

The pressure die is the backbone of the mandrel bending process, ensuring every tube bend is precise and repeatable. During tube bending the pressure die applies a controlled force to the tube as it is bent around the bend die. This pressure is critical to maintain the tube shape and prevent unwanted deformation such as flattening or wrinkling especially when bending tight radii or thin walled tubing.

As the bend die rotates and the mandrel supports the tube from the inside, the pressure die works in conjunction to keep the tube pressed against the bend die. This coordinated action allows the tube to achieve the desired bend radius while maintaining its structural integrity and original shape. The pressure die is designed to accommodate various tube sizes and materials making it a versatile tool for manufacturers who want to produce high quality bends across many applications.

By using a robust pressure die system manufacturers can support the tube throughout the bending process, minimize distortion and produce bends that meet strict quality standards. This is essential for industries where tube bending quality is critical.

Setting Up the Bending

Setting up the bending is critical and affects the accuracy and efficiency of the tube bending process. First you need to select the right tooling, the bend die, pressure die and mandrel, all of which must match the tube material, diameter and wall thickness. The right tooling ensures the tube can be bent to the required centerline radius and bend radius without compromising the tube's integrity.

Once the tooling is chosen the bending machine needs to be set up for the specific job. This involves setting the bend radius, centerline radius and degree of bend on the machine's controls. Calibration is key to ensure the machine operates within the specified tolerances and delivers repeatable and precise results every time.

Proper alignment and clamping of the tube is also important. The tube must be positioned correctly in the bending machine, using clamps and fixtures to prevent any movement or distortion during the bending process. By setting up the bending correctly manufacturers can ensure every tube bend is formed to spec, maximize productivity and minimize errors or rework.

Operator Controls and Monitoring

Modern tube bending machines have advanced operator controls and monitoring systems to improve accuracy and efficiency of the bending process. The operator interface has a user friendly control panel where operators can input key parameters like bend radius, degree of bend and material type. Many systems have programmable bending sequences and automatic setup features to reduce setup time.

Real time monitoring is a must have feature, providing operators with instant feedback on the tube bending process. The system tracks critical data like current bend radius, degree of bend and even tube temperature so operators can make adjustments on the fly to maintain accuracy and quality. Alerts and warnings notify the operator of any issues like excessive deformation or machine malfunction so they can intervene quickly to prevent defects.

By using these advanced controls and monitoring features manufacturers can achieve consistency, reduce waste and ensure every tube bend meets the highest quality standards. Integration of these systems into the bending process is key to efficiency and great results.

Choosing the Right Mandrel

Choosing the right mandrel is key to a successful tube bending process. A mandrel is a metal bar insert that supports the pipe or tube during bending, preventing collapse and keeping the tube shape. Its main job is to support the tube's inside diameter and minimize deformation during bending.

You need to determine the correct mandrel size based on tubing characteristics such as wall thickness, bend radius and tube outside diameter. Key points are:

- For soft tubes a hard mandrel (like a steel rod) is preferred to keep the shape.

- For hard tubes a soft mandrel is used to bend without damaging.

- The mandrel should be slightly smaller than the tubing's inside diameter for a good fit. A bad fit will cause ripples on the inside of the tube and surface imperfections.

Mandrel balls are good for supporting during bigger bends and increasing the roundness of the mandrel end will support thinner materials during bending. Choosing the right mandrel style and material will give you accurate bends and good product quality. A mandrel makes it easier to achieve that.

Advantages of CNC Mandrel Bending

CNC mandrel bending has many advantages that make it a great option for many industries. One of the biggest is the control over the bending parameters which gives more precision in the bends. This precision means each bend is consistent which is critical for applications that require tight tolerances and repeatability.

CNC technology makes bending cost effective by:

- Using the right combination of mandrel and wiper dies to avoid under or over-tooling.

- Reducing scrap rates and ensuring stability in processing which means higher productivity and lower operational costs.

- Using a mandrel during bending to prevent collapse and wrinkling and get higher quality products.

Industry 4.0 technologies like IoT and AI have improved the efficiency and accuracy of CNC mandrel bending machines. These technologies allow real time monitoring and reduce downtime making CNC mandrel bending a more powerful tool in modern manufacturing.

Applications of CNC Mandrel Bending

It's used to produce complex shapes in many industries. In the automotive industry it's used to make components like exhaust systems, roll cages and hydraulic lines, for high precision and repeatability. Accurate and consistent bends are critical for performance and safety of automotive components.

In the aerospace industry CNC mandrel bending is used to make fuel lines, hydraulic systems and structural elements. This process is compatible with high performance materials like titanium which are used in aerospace and racing industries for their strength and durability. The tight tolerances and high precision required in aerospace makes CNC mandrel bending essential for producing lightweight, durable tubing that meets strict standards. This ensures components are reliable and defect free, critical for safety and performance in aerospace.

CNC mandrel bending is used in:

- Furniture making to create stylish and strong metal frames, tubes for chairs, tables and shelving units.

- Making complex frames and metal legs to enhance the look and functionality of furniture.

- Shipbuilding to make pipelines and railings, for durability in marine environments.

Types of CNC Mandrel Bending Machines

There are different types of CNC mandrel bending machines to suit specific bending requirements. Plug mandrel machines are for thicker tubes and have a solid rod inside the tube. They are best for long radius bends in thick walled tubes, structural integrity and precision.

Form mandrel machines support thick tubes with a metal rod with a curved end for tubes with nominal pipe diameter. These machines provide additional support during bending to prevent deformation and get accurate bends with a solid mandrel.

Ball mandrel machines have a ball at the end of the mandrel to get precise bending in curved sections. They are good for complex bends in tubes with varying diameters and are known for their accuracy, versatility and features.

Many CNC mandrel bending machines also have operator controls to switch between inch and metric units for machine setup and operation.

Quality Control and Inspection

Quality control and inspection is crucial to producing high quality tube bends to exacting standards. We start with a full inspection of the raw tube material, checking diameter, wall thickness and material properties. During the bending process we visually inspect and measure to ensure the bend radius, degree of bend and tube shape is within tolerance.

After bending is complete the tube is inspected again, which may include dimensional checks and non destructive testing to ensure structural integrity. Additional processes such as cleaning, deburring and packaging may be performed to prepare the tube for its intended use.

By having a full quality control and inspection process in place manufacturers can ensure every tube bend meets the specification, reducing the risk of defects and increasing customer satisfaction. Consistent quality control is key to a good reputation in tube bending.

Troubleshooting Common Problems in CNC Mandrel Bending

Even with precision, problems can still occur during CNC mandrel bending. One common issue is wrinkling on the inside radius, caused by under pressure of the direct die. Proper setup of the wiper die tip prevents terminal bulges from becoming wrinkles at the end of the bend. During bending the longer side of the tube (outer radius) is prone to thinning and tearing so proper mandrel placement is key to supporting the structure and preventing damage.

Excessive flattening of the outside square outer radius is usually caused by too much pressure from the direct die. Adjusting the pressure and correct placement of the mandrel nose helps control the material flow and prevent buckling and excessive thinning and round flattening. In mandrel bending a solid support is inserted to prevent deformation, while empty bending relies solely on the tube's physical strength to maintain shape without internal support.

Inconsistent machine pressure or worn out tooling can also cause bending problems. Regular maintenance and inspection is key to identifying and addressing these issues so you get consistent and high quality bends and no breaks in the process. Tubes with immense physical strength like thick walled or high strength alloys are better suited for empty bending processes. The physical strength of the tube material determines if mandrel or empty bending is used for a given application.

Innovations in CNC Mandrel Bending Technology

CNC mandrel bending is evolving with new technology. Next gen machines are being developed to work with high strength alloys and composite materials. This opens up more applications and more robust manufacturing solutions.

IoT and AI in CNC bending machines means real time monitoring and less downtime. These technologies allow manufacturers to track machine performance, predict maintenance needs and optimise the bending process for more efficiency and precision.

Future of CNC mandrel bending is more automation and robotics. As these come to market CNC mandrel bending will be at the forefront of manufacturing across all industries.

Conclusion

CNC mandrel bending is a mighty tool in modern manufacturing. Its ability to produce precise and repeatable bends makes it essential for industries like automotive, aerospace and construction. By understanding the components, process and maintenance of CNC mandrel benders you can get great results and optimise your production.

As technology moves forward the future of CNC mandrel bending looks good. Advances in material, automation and real time monitoring will make it even more efficient and versatile. By embracing these you can stay ahead of the game and meet the ever changing demands of your industry.

FAQ's about Mandrel Bending

What is mandrel bending?

Mandrel bending is a precise tube bending technique that gives smooth, accurate bends and maintains the material strength and quality. This is crucial for high integrity applications.

What industries use mandrel bending?

Mandrel bending is used in automotive, aerospace and furniture design industries. It's used in these industries for precise and smooth bends for structural and aesthetic purposes.

How does mandrel bending prevent issues during bending?

Mandrel bending prevents flattening and tearing of material by providing internal support through a rod inserted inside the tube during bending. This gives a smooth bend and maintains the material integrity.

What is a mandrel?

A mandrel is a metal bar used to support pipes or tubes during bending so they don't collapse. This is important for precise bends in metalworking.

What are the benefits of mandrel tube bending?

Mandrel tube bending gives structural integrity, precision for tight tolerances and consistent production quality. It's ideal for applications that require durability and accurate bends.