Introduction

Summary

- Electrical Discharge Machining (EDM) is a precision process that uses electrical discharges to remove material, to create complex shapes that can't be done with traditional methods.

- Types of EDM machines are Wire EDM, Sinker EDM and Hole Drilling EDM, each for specific applications, to boost productivity and precision in manufacturing.

- EDM has many advantages like high precision, versatile with hard materials and low mechanical stress but has slower machining speed and high operational cost.

Understanding Electrical Discharge Machining (EDM)

EDM or the edm process, is not just another manufacturing method; its a precision technique

that removes material from electrically conductive materials through thermal erosion and

vaporization caused by electric discharge machining and electrical discharges. The ability to

remove material without direct contact makes EDM necessary for creating complex geometries

that traditional methods can't achieve, showing off the edm process.

CNC machining is another advanced manufacturing process used alongside EDM, providing high

precision and versatility for making complex parts in many industries.

There are different types of conventional edm machines for different applications. While the

principle remains the same—using electrical discharges to erode material—the machines vary in

design and functionality, offering unique advantages in certain situations. In addition to

wire EDM, traditional EDM is used for making complex shapes and reducing electrode wear, while

volume EDM is for making complex, high precision molds and cavities through spark erosion.

Knowing how EDM works and the types of machines available helps you make informed decisions

for your projects.

How EDM Works

Each spark from the EDM electrode creates a localized temperature spike, sometimes up to 12,000 °C. This intense heat melts and vaporizes tiny pieces of the workpiece, allowing for precise machining through spark machining. But the process requires a controlled environment to work. Dielectric fluids, like hydrocarbon oils or deionized water, fill the spark gap to prevent unwanted discharges and maintain a stable machining environment, while spark eroding improves the process. Choosing and optimizing dielectric fluids is a critical part of the electrical discharge machining process as it affects machining performance, surface finish and tool life. Spark edm also plays a big role in that.

Accurate voltage monitoring optimizes spark energy, so material removal is reliable and efficient. Such precise control over electrical discharges makes EDM very precise, can achieve detailed and accurate results.

Types of EDM Machines

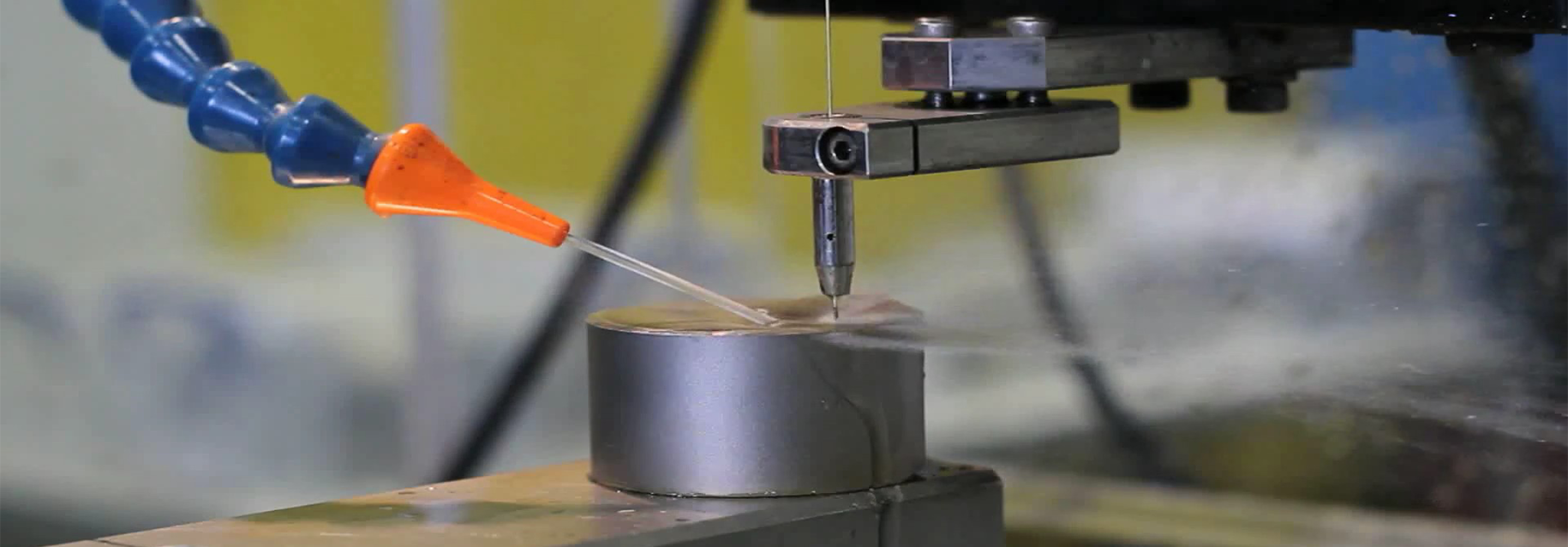

EDM machines come in several types, each for specific needs and applications. The three main types are Wire EDM, Sinker EDM and Hole Drilling EDM:Wire EDM machines use a thin wire, usually made of brass wire or other conductive alloys, to make 2D cuts. The wire electrode is the cutting tool, fed through the workpiece to make precise cuts.

- Wire cutting is the process of using a wire electrode to remove material for complex geometries.

- Wire burning, also known as wire EDM, uses electrical discharges to erode metal without contact, good for delicate features.

- Wire erosion is the principle by which wire EDM machines make precise cuts through non-contact electrical discharges.

- Tube shaped electrodes are used in some wire EDM processes to make internal contour cutting and complex geometries.

- This is good for precise profiles and sharp corners, good for complex geometries.

- Wire EDM machines can be unattended, so more productive. And wire cut edm is a technique that makes these machines more versatile, especially in wire cut applications.

Hole Drilling EDM is a specialized type used for drilling precise holes in applications like rocket engines and gas turbine blades. This can drill holes as small as 0.0015 inches in diameter, very versatile and precise. Good for making precise, small and deep holes with minimal defects or burrs. Sectors like injection molding and die-casting tool-making use these EDM techniques for precision and efficiency, including small hole edm.

Electrical Discharge Machining (EDM) includes three main types—Wire, Sinker, and Hole Drilling—each with distinct electrodes, workpiece needs, and practical limits for manufacturing engineers. This table summarizes key manufacturability specs from the blog for process selection.

| EDM Type | Electrode Type | Workpiece Needs | Tolerance | Setup/Wear Issue | Key Applications |

|---|---|---|---|---|---|

| Wire EDM | Brass wire 0.001-0.01 in. | Conductive, any thick | Profiles ±0.0001 in. | Continuous feed, low wear | 2D cuts, sharp corners |

| Sinker EDM | Graphite/copper formed | Conductive, immersed | Cavities fine detail | Multiple electrodes needed | 3D molds, dies |

| Hole Drilling | Tubular rotating | Conductive hard mat. | Holes ≥0.0015 in. dia. | High-pressure flush | Turbine blades, injectors |

History of EDM

Over the years, EDM has come a long way. Improvements in EDM machine design, specialized electrode materials and advanced dielectric fluids have all contributed to the evolution of the EDM process. Today EDM is a widely used discharge machining process to fabricate complex parts from hard, electrically conductive materials across aerospace, automotive and electronics industries. The continued refinement of EDM machines and processes has made it an indispensable tool in precision manufacturing.

Key Components of EDM Machines

When machining hardened steel you need to carefully select the electrode material and specify the side clearances to optimize the machining performance and tool life.

Automation features like tool changers and electrode wear compensation makes the process more efficient and accurate, cooling and filtration systems keeps the performance optimal and tooling life longer.

Electrode Tool

The electrode tool is a critical part of the EDM process, the material choice affects the erosion rate and machining efficiency.Common materials for EDM electrodes are:

- Graphite electrodes: high wear resistance

- Copper: good thermal conductivity, reduces electrode wear

- Copper-tungsten: good thermal conductivity, reduces electrode wear

- Brass

Electrode design is important to achieve precise part geometry and optimize the machining performance. Techniques like reversing polarity or using copper tools can reduce the electrode wear when creating electrodes for hard materials, ensures consistent precision and extends the electrode life.

Dielectric Fluid

Dielectric fluid plays multiple roles in the EDM process:- Machining accuracy, surface finish and tool wear.

- Cooling the electrode and workpiece to prevent overheating during machining. Use pressurized dielectric liquid to wash away solid particles, keep the machining area stable and consistent.

Dielectric Fluid Management

Dielectric fluid management is the cornerstone of the edm process, it directly affects the performance and life of the edm machines. The dielectric fluid - a hydrocarbon oil or deionized water - serves several important functions: it insulates the electrode and workpiece, facilitates controlled electrical discharges and flushes away eroded particles during material removal.Maintain the quality, temperature and circulation rate of the dielectric fluid is important for consistent machining results. Proper management prevents excessive electrode wear, ensures stable spark generation and minimize the risk of short circuits. Modern EDM machines are equipped with advanced dielectric fluid management systems, including filtration units, cooling mechanisms and automated circulation controls. These features optimize the edm process, increase material removal rate and contribute to the overall reliability and efficiency of EDM operations.

Servo Controlled Feed

Servo controlled feed is important to maintain the optimal spark gap in EDM machines which is very critical for consistent machining accuracy. Feedback mechanism in servo systems improves stability and reduces errors, ensures high tolerance production and creation of intricate cavities.High accuracy in table movement ensures repeatable results, tight tolerances and complex geometries in EDM machining.

Applications of Electrical Discharge Machining

- Mold and die making

- Aerospace

- Automotive

- Medical device manufacturing

- Electronics for high precision and complex electronic components

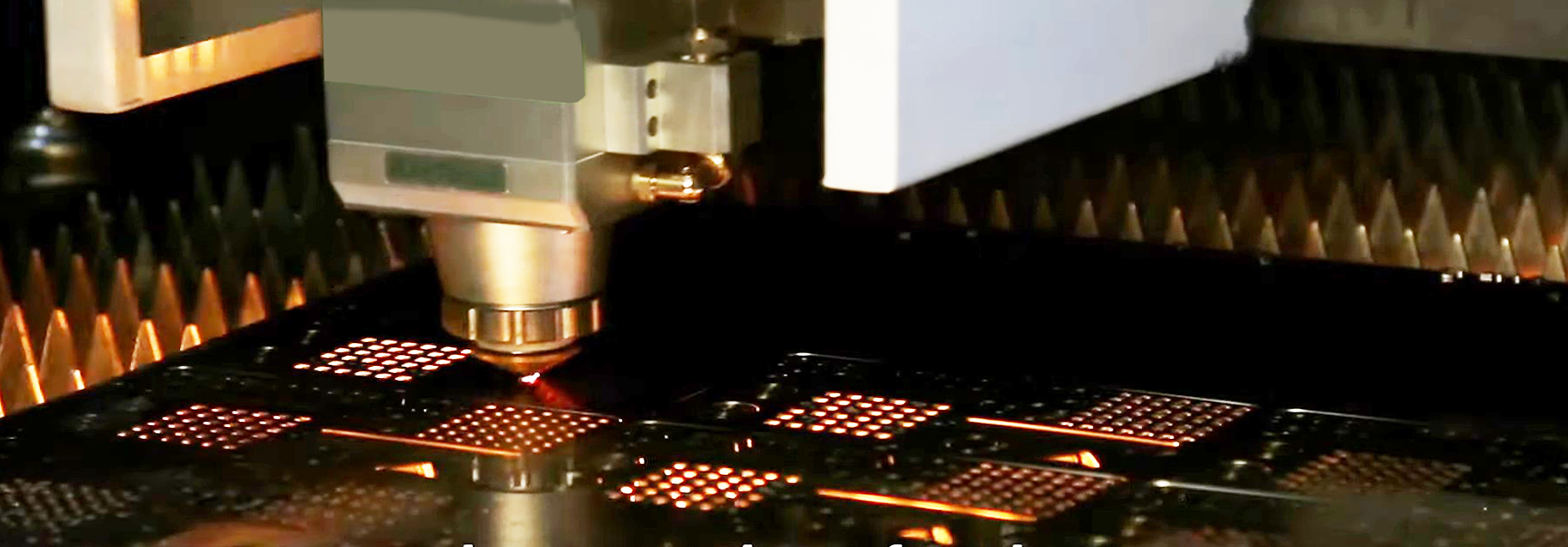

Mold and Die Making

In mold and die making EDM is a must for creating detailed extrusion dies and injection molds. The process starts with conventional cutting to remove large amounts of material, then fine machining with EDM for precision. This combination of methods is efficient and allows for internal contours that are hard to achieve with traditional machining.Protolabs for example has lead times for die molds by first machining them in standard milling then EDM. This approach maximizes efficiency and produces high quality molds for plastic injection molding and metal die casting.

Aerospace and Automotive

In aerospace and automotive EDM is critical for manufacturing complex parts that require high precision and reliability. EDM's ability to produce intricate geometries and tight tolerances makes it perfect for parts like turbine discs and other critical parts from high grade nickel alloys.Medical Device Manufacturing

Medical device manufacturing relies heavily on Electrical Discharge Machining (EDM) for producing highly detailed and biocompatible parts. EDM is used to create parts for medical devices including:- Pacemakers

- Cochlear implants

- Spinal fixtures

- Dental implants

The precision and minimal mechanical stress of the EDM process ensures the structural integrity of these delicate parts is maintained. This is critical for the reliability and performance of medical devices and directly impacts patient care and outcomes.

Advantages of Using EDM

Electrical Discharge Machining has many advantages that make it the go to choice in many industries. EDM stands out from traditional machining methods with its ability to produce complex shapes with tight tolerances and better surface finishes.

EDM also doesn't require special tooling making it cost effective and ideal for parts that are hard to process with conventional methods.

Precision and Accuracy

EDM's precision and accuracy is key:- Tolerances as tight as ±0.0001 inches.

- Suitable for intricate designs that require high precision.

- Tight tolerances are critical for industries that demand detailed and accurate parts. Learn more about manufacturing processes for precision part production.

Material Versatility

EDM's material versatility is another big plus. It can machine hard metals and alloys that are impossible to cut with conventional methods. This is especially useful in aerospace where complex geometries are critical for component reliability and performance.The medical device industry also benefits from EDM's ability to produce intricate designs, precision and biocompatibility. Precise electrical discharges in EDM achieve better surface finish and tolerances on tough materials, minimal mechanical stress preserves the integrity of delicate parts.

Reduced Mechanical Stress

EDM minimizes deformation, delicate parts stay in shape during processing. This is critical for components that require high precision and integrity.EDM generates minimal forces, keeps delicate parts in shape and integrity. This combination of minimal deformation and minimal forces means better quality and precision in machining delicate parts.

Advantages over Traditional Machining

Unlike traditional machining that struggles with hard or brittle materials, edm can machine hardened steels, exotic alloys and other tough electrically conductive materials. The process imposes minimal mechanical stress on the workpiece, reducing the risk of distortion or damage. Edm can also reproduce intricate shapes and sharp internal corners in one operation, eliminating the need for multiple machining steps. Thats why edm is a must have tool for industries that require complex high precision parts.

Challenges and Limitations of EDM

Managing EDM processes and getting the most out of them requires understanding these challenges.

Slow Speeds

One of the limitations of EDM is slower speeds than traditional methods like turning and milling. EDM's lower material removal rate affects overall machining time and efficiency.This has to be factored into production planning and timelines to get the job done on time.

Electrode Wear

Electrode wear is a big challenge in EDM. Material loss from the electrode during machining affects accuracy and often requires frequent replacements to maintain precision. This wear changes the dimensions of the machined surface and causes tool wear and inaccuracies that need to be managed to get consistent quality.High Costs

High costs are another issue with EDM. The factors that can increase overall costs are:- Electricity used in EDM operations

- Equipment purchase costs

- Maintenance costs

- Electrode replacement costs

Choosing the Right EDM Machine for Your Needs

Choosing the right EDM machine involves many factors. Consulting an applications engineer will help you assess the project design and determine if EDM is the right solution. Sometimes design changes will eliminate the need for EDM altogether so initial consultation is key.

When buying an EDM machine consider:

- Type of machine

- Precision required

- Material compatibility

- Operating costs

Choosing the right generator for EDM machining is critical to operation. A matched generator will improve the machine's performance and productivity so its worth the investment for your processes.

Real-World Examples of EDM

- Mold and die making: EDM makes intricate molds with sharp corners and fine details for high end products.

- Aerospace: EDM is used to make complex parts that require high precision and reliability.

- Automotive: EDM makes complex, precise and reliable parts.

EDM Future

As tight tolerances and complex geometries continue to grow EDM will play a bigger and bigger role in modern manufacturing. Research into better electrode materials, more efficient dielectric fluids and smarter EDM machines will further improve the accuracy, speed and versatility of the EDM process. With these advancements EDM will remain at the forefront of precision machining and manufacturers will be able to push the boundaries of what's possible in component design and fabrication.

Conclusion

FAQ's about Electrical Discharge Machining

What is Electrical Discharge Machining (EDM)?

Electrical Discharge Machining (EDM) uses controlled electrical sparks to erode conductive materials. It creates complex geometries in hardened steels without mechanical force. Tolerances reach ±0.002 mm. EDM works where CNC fails on sharp corners or tough alloys.

What are the main types of EDM machines?

Wire EDM cuts precise 2D profiles (±0.0025 mm tolerance). Sinker EDM forms 3D cavities and molds. Hole Drilling EDM creates tiny deep holes (0.0015 in. diameter). Each type suits aerospace turbines or injection dies on hard materials.

What are the advantages of EDM?

EDM achieves micron precision (±0.0001 in.) with no mechanical stress. It works on any conductive material like Inconel or tungsten. EDM tolerances: 2-5 μm; surface finish Ra 0.2-0.8 μm. Suits medical implants and molds.

What Are EDM Limitations and Costs vs CNC?

EDM removes material slower than CNC with electrode wear. Best for low-volume precision, not high-speed production. Lead times: 3-10 days vs CNC's 1-3 days. Used for complex hard parts.