Introduction

Summary

- Sheet metal fabrication is the process of transforming flat sheets into functional parts through cutting, bending and joining, it impacts aerospace and manufacturing.

- Material selection is key in sheet metal fabrication, you need to consider strength, durability and cost, common materials are aluminum, stainless steel and specialty metals like titanium and nickel alloys.

- Innovations in sheet metal fabrication like AI, robotics and 3D printing are making it more efficient, precise and able to produce complex designs, the trend is towards more automation in the industry.

Understanding Sheet Metal Fabrication

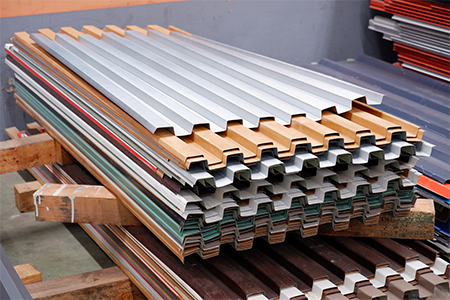

Sheet metal fabrication is the process of taking flat sheets of metal and turning them into parts and structures through cutting, punching, folding and assembling. It's used in many industries such as aerospace, medicine and consumer electronics to name a few.

Industries like production, agriculture, manufacturing, oil and gas rely heavily on sheet metal fabrication to make components and structures. Understanding the process ensures efficient designs for many applications. Applications range from intricate aerospace components to robust agricultural machinery, they're diverse and important.

Sheet metal fabrication is used to make parts and components for industries like transportation, aerospace and manufacturing to produce complex functional parts for many applications. The journey of sheet metal from a flat sheet to a finished product is a series of steps that require precision, expertise and the right materials. Each step in sheet metal fabrication turns raw material into a functional and often complex part ready for the task.

Key Processes in Sheet Metal Fabrication

Several stages in sheet metal fabrication turn flat sheet metal into functional parts. These processes are used for prototypes and production parts for various industries. These stages can be broken down into cutting, bending and joining techniques.

Each process has its own tools and techniques and is part of a successful sheet metal fabrication project.Sheet metal stamping: A process of pressing and forming sheet metal into specific shapes using dies and stamping presses.

Cutting Techniques

Cutting sheet metal, the first stage of fabrication, uses various techniques depending on the material and outcome. Here are some:- Laser cutting

- Plasma cutting

- Water jet cutting

- Shearing

For example, laser cutting can cut up to 30mm thick metal, efficient, low cost and high productivity. Laser plasma cutting is used for thicker metal pieces where surface finish is not critical, using an energized gas to create plasma. A plasma cutter uses an electrically charged beam of compressed ionized gas (plasma) to cut through electrically conductive metals, often resulting in a rough cut with burrs and oxidation around the edges.

Water jet cutting uses a high pressure stream of water, suitable for various thicknesses and no heat related issues. Waterjet cutting uses scissor like blades for straight cuts.

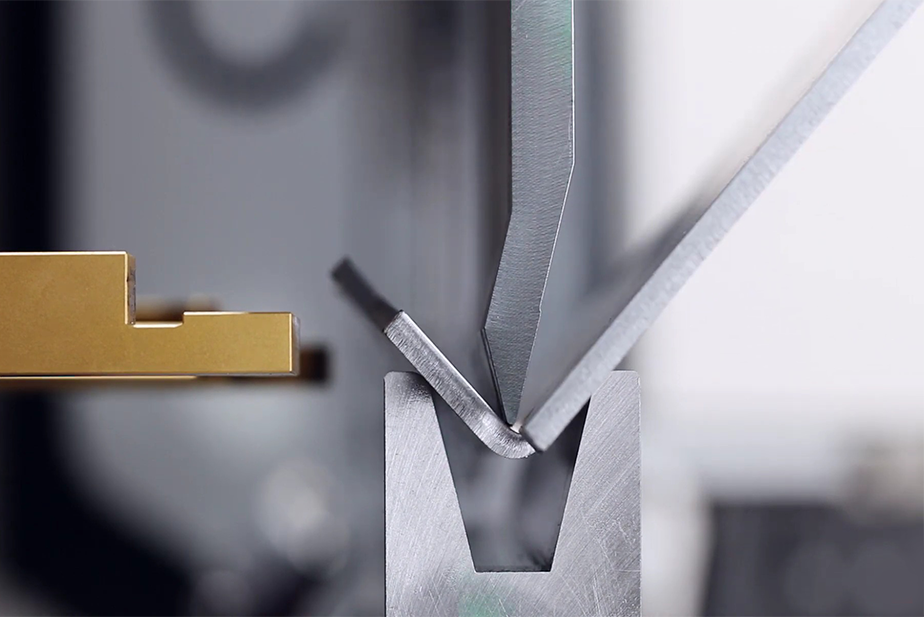

Bending and Forming

Bending is used in sheet metal to form using press brakes and rolling machines to get specific shapes. Bending is to fold the workpiece along a straight line to get an angle or shape. Control of bending parameters is crucial to get the final geometry as per design specifications. Press brakes can create sharp bends and angles in metal while rolling machines can create flat, straight or curved geometries.Deep drawing is used to create hollow parts by using a punch to shape flat sheet metal into a die to get complex shapes and geometries. Common forming techniques in sheet metal are:

- Bending

- Stamping

- Stretching

- Rolling

- Deep drawing- Each serving a unique purpose in the fabrication process.

Joining Methods

Joining methods in sheet metal fabrication put parts together to form a finished product. Welding for example melts the joint edges together as it cools, MIG welding, TIG welding, robotic MIG welding are common methods. MIG and TIG welding produce strong durable joints that are permanent and can be used on many materials.Soldering is done below 200°C and the base metal doesn't melt, it uses a filler metal to join parts, but the strength of solder joints are generally weaker than welded joints. Soldering and brazing is done below the melting point of the base metals, welding is done above the melting point of the metal to create a permanent joint. Riveting is another common fastening method along with bolts and nuts, strong and reliable joints in sheet metal fabrication.

Material Selection for Sheet Metal Fabrication

- Cutting

- Bending

- Forming

- Heat treatment

- Welding

- Joining

- Assembly

- Metal fabrication processes

- Cutting process

Post processing operations like heat treatment and surface finishing are also important to improve the quality and characteristics of the finished product.

Common Materials

Common materials in sheet metal fabrication are:- Aluminum: lightweight and durable, suitable for many applications.

- Stainless steel: used in medical and food industry for its hygienic properties.

- Mild steel: versatile and cost effective.

- Copper: good conductivity, ideal for electrical applications.

Aluminum series 5xxx is more ductile, less tearing during bending, stainless steel and titanium are used in aerospace industry for its lightweight and durable properties. Sheet metal is recyclable which makes it eco friendly and used in many industries.

Specialty Metals

Specialty metals have special properties for high performance applications. Titanium and nickel alloys are strong, corrosion resistant and lightweight. Titanium is especially good in aerospace and medical applications for its strength to weight ratio and corrosion resistance.Nickel alloys are heat resistant and stable for high stress industrial applications. These specialty metals are used in industries like aerospace, medical and energy where their unique properties give them an advantage.

Choosing the Right Material

When selecting materials for sheet metal fabrication properties, availability and cost are key. These factors affect project goals like strength, corrosion resistance and budget. Informed material selection makes the final product functional and fabrication efficient.Choosing the right material makes the final product work. Considering the application's needs while balancing material properties and cost helps manufacturers get the best results.

Finishing Options for Sheet Metal Parts

- Surface preparation

- Polishing

- Powder coating

- Anodizing

- Passivation

- Laser marking

A finish's suitability depends on the part's requirements and material properties. Surface finishes are chosen to increase durability, prevent corrosion and achieve the desired look by depositing a thin layer of material onto the metal surface.

Standard Finishes

Standard finishes for sheet metal parts are:- Anodizing

- Plating

- Powder coating

- Standard painting methods

- Sheet metal finishes

Bead blasting uses abrasive beads to smooth surfaces, gives a matte finish. Suitable for small and big parts, bead blasting removes tooling marks and blemishes efficiently. Chem Film increases corrosion resistance and conductivity, leaves surfaces with a yellow/gold tint. It's also a base for paint, makes the finished product look better. Chem Film adds very little thickness to the surface, perfect for applications where dimensional accuracy is critical.

Anodizing

Anodizing involves an electrochemical process that creates a stable oxide coating on parts or structures. There are three main types of anodizing:- Type I: Uses chromic acid for a thin, highly corrosion-resistant coating.

- Type II: Uses sulphuric acid for uniform, attractive surfaces with good corrosion resistance.

- Type III: (Not described in detail in the text). Additionally, chromate conversion coating can enhance corrosion resistance.

Each type uses different acids and processes. Type III anodizing, using sulphuric acid at lower temperatures and higher voltages, produces thicker coatings ranging from 0.025 mm to 0.05 mm. It offers corrosion resistance and enhanced wear resistance compared to Type II. Preparation for Type II anodizing often involves bead blasting to a #120 grit finish.

Powder Coating

Powder coating is a dry powder that is baked to produce a finish. Powder paint is applied and then cured in an oven to form a tough, corrosion resistant layer on the metal surface. Powder coating comes in many colors and is great for a strong, wear resistant layer. But can't be applied to internal surfaces.Electroless Plating

Electroless plating is a chemical reaction not electrical means. It's great for applications that require uniform thickness and aesthetic finishes. Electroless nickel plating gives you a uniform nickel coating for corrosion, oxidation and wear protection. Thickness range for electroless nickel plating is .0001” and above. Gold plating gives you a corrosion resistant finish and tarnish resistance and excellent solderability, so it's great for high precision applications.Design Considerations for Sheet Metal Parts

Tolerances and Precision

Uniform wall thickness is key to sheet metal part integrity. Dimensional inspection in sheet metal fabrication ensures parts meet specified dimensions and tolerances. Tools used for dimensional inspection are callipers, micrometers and high precision lasers.Advanced techniques in sheet metal fabrication allows for production of parts with tight tolerances when designing sheet metal parts.

Hole Placement and Size

Proper hole placement keeps the structural integrity of sheet metal parts. Hole diameters should be at least the material thickness and if too close to the edge the material will tear or deform.Threaded inserts can be used for durable non permanent threaded connections in sheet metal parts especially when repeated assembly and disassembly is required.

Bend Radii and Reliefs

Key considerations for bend reliefs and bend radius are:- Bend reliefs should be wider than the material thickness to prevent tearing.

- The inside bend radius should be at least the same or larger than the material thickness to prevent tearing and maintain structural integrity.

- Small bend heights make forming and positioning in the press brake difficult and can cause deformation.

Bending is complex because of the calculations and alignment trials that need to be done accurately. Considering design, bending parameters and tooling factors together will maximize manufacturing efficiency and product quality and ensure the final product meets all specs and requirements.

Quality Control in Sheet Metal Fabrication

Quality control is key to the sheet metal fabrication process, every sheet metal part must meet performance, durability and safety standards. Sheet metal fabricators use a combination of advanced inspection methods and testing protocols to verify each stage of metal fabrication meets client specifications and industry requirements. By controlling quality fabricators can minimize defects, reduce waste and deliver metal parts for many applications.Inspection and Testing Methods

To ensure sheet metal parts are sound fabricators use various inspection and testing methods throughout the metal fabrication process. Visual inspections are done to check for surface imperfections such as scratches, dents or finish inconsistencies. Dimensional checks are done using precision tools to verify sheet metal parts meet specified measurements and tight tolerances, this is critical for parts that require precise fits.Material testing is another key part of the process, testing the physical and chemical properties of sheet metal materials. This includes corrosion resistance, tensile strength and overall durability to make sure the chosen materials will perform as expected in their environment. Functional testing may also be done, simulating real world conditions to make sure the finished metal parts meet all operational requirements. These thorough quality checks help maintain the reputation of sheet metal fabricators and the success of every metal fabrication project.

Consistency and Reliability

Consistency and reliability is achieved by following strict quality control standards and continually improving sheet metal fabrication processes. Top sheet metal fabricators have robust inspection protocols at every stage from material selection to final assembly. Using high quality sheet metal materials and advanced fabrication techniques – laser cutting, water jet cutting and plasma cutting – ensures custom sheet metal parts are made with precision and repeatability.Staying up to date with the latest metal fabrication processes allows fabricators to be more efficient and stay ahead of the competition. By combining skilled craftsmanship with the latest technology, sheet metal fabricators can deliver custom sheet metal solutions that meet each client's unique needs whether it's high volume production runs or specialty, complex designs.

Applications of Sheet Metal Fabrication

Sheet metal fabrication is used in industries like aerospace, renewable energy and medical devices. Sheet metal fabrication affects many applications across many sectors. It supports end use production by delivering finish ready components for functional use.

Its applications range from manufacturing components for kiosks and vending machines to creating visual merchandise and product displays in retail to meet all your manufacturing needs.

Aerospace Components

Titanium's high strength, low weight and corrosion resistance makes it ideal for aerospace applications. Nickel alloys are used in high temperature environments for strength and oxidation resistance. Aerospace components made from sheet metals include:- Aircraft bodies

- Fuselages

- Skins

- Engine components

Automotive Industry

Over 50% of car parts are made from sheet metal, so it's a big deal in the automotive industry. Sheet metal provides strong framing for car parts and is lightweight because of its thinness.Sheet metal parts in vehicles are formed through processes like stamping and CNC bending for precision and quality. Floor pans are a critical part of automobile manufacturing, usually made through sheet metal stamping and welding.

Construction and Architecture

Sheet metal fabrication is being used more and more for building cladding, roofing and structural elements in construction. Sheet metal is used to create decorative elements like facades, railings, gates and intricate exterior cladding to make the building look good. Notable projects like the Walt Disney Concert Hall in Los Angeles show how sheet metal can be used innovatively in architecture. The intended use of the metal determines the selection process and affects factors like durability and performance.Medical and Food Industries

Preferred materials for MRI applications in healthcare are stainless steel and aluminum, for durability and resistance to magnetic fields. In food production and preparation, stainless steel is preferred for sheet metal fabrication for hygiene and health standards.High precision tools made from sheet metal are crucial in healthcare for intricate surgery tools and scalpels that require exactness.

Pros and Cons of Sheet Metal Fabrication

Benefits

Cost is a big factor in material selection for sheet metal fabrication, it affects the overall project feasibility. As production volume increases, the cost of sheet metal parts gets cheaper per part.Lower setup cost is one of the advantages of PCBWay's sheet metal fabrication services compared to CNC Machining. Sheet metal fabrication requires low investment in tooling and preparation cost, hence more efficient.

Limitations

High initial cost for custom tooling in some sheet metal process can make it uneconomical for low volume prototypes in low volume production. Achieving complex bends in thicker material can be difficult, often requires special technique to ensure accuracy.Some fabrication process requires combining multiple process, which can complicate production and extend lead time.