Introduction

Key Points

- Injection molding is a versatile process for making high quality plastic products with precise dimensions and complex designs.

- The injection unit, clamping unit and mold are the key components of an injection molding machine that affect the process and product quality.

- Optimizing mold design, material preparation and operational parameters like injection speed and cooling time is crucial to minimize defects and overall production efficiency.

Understanding Injection Molding

Plastic injection molding is a popular way to make plastic products. This is used in the manufacturing industry. It involves injecting molten plastic into custom plastic injection molds to make items with precise dimensions and intricate details. Most injection molding operations follow the standard process description, but there are other molding methods used for specific applications. This is used to make:

- Electronic housings

- Containers

- Bottle caps

- Automotive interiors

- And more

Injection molding is used to make plastic parts for many industries.

The process is very versatile, can handle different types of plastic materials, from thermoplastic materials to thermosetting polymers, each with its own properties for different applications.

Designing parts for injection molding requires consideration of the end-use requirements, structural integrity and material flow during the molding process. While injection molding has many advantages such as high efficiency and can make complex shapes, it also has its challenges. High upfront tooling costs and limited to very intricate designs can be a big hurdle. But with the right approach and understanding, these challenges can be managed.

The injection molding process is fast and can make large volume of identical parts. This is ideal for mass production, especially for high volume production runs where thousands or millions of parts are needed.

The base material used in injection molding is plastic resin, which is melted and injected into molds to form the desired shape. Optimizing material selection, mold design and machine settings helps manufacturers to achieve high quality and cost effective manufacturing process. Understanding injection molding is the first step to mastering this manufacturing method.

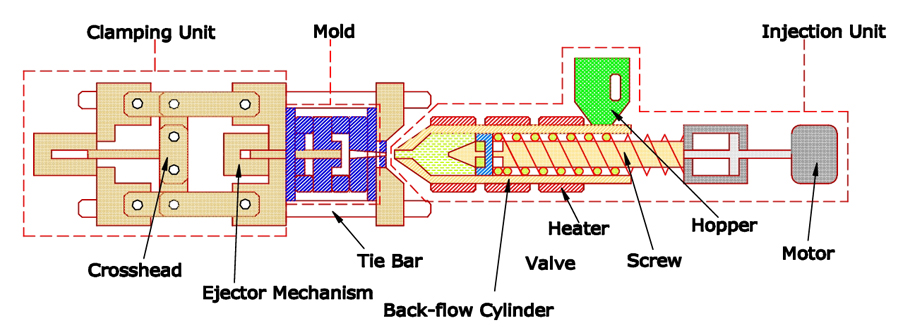

Key Components of an Injection Molding Machine

An injection molding machine is a big piece of equipment that plays a big role in the injection molding process. It has many parts, each one doing a specific job that contributes to the overall efficiency and quality of the molded parts.

The main parts are the material hopper, the injection unit and the clamping unit. Together these parts work in harmony to melt plastic, inject it into the mold and keep the mold closed during the injection process.

Injection Unit

The injection unit is the heart of the injection molding machine, it melts plastic pellets and directs the molten material into the mold cavity. This unit has several parts:

- The hopper, that feeds plastic pellets into the barrel.

- The barrel, where the pellets are heated until they become molten plastic.

- The screw, that pushes the molten plastic forward, forcing it through a nozzle and into the mold cavity.

The injection unit is key to the whole injection molding process. Temperature control, cylinder temperature and injection speed are critical to get the plastic to flow into the mold without defects. The injection ram plays a big part in this.

Adjusting the injection speed and pressure can help the flow of molten plastic, reduce the chance of air bubbles or incomplete filling of the mold cavity. For stiffer or higher viscosity plastics, more injection pressure may be needed to fill the mold properly and avoid defects. Fine tuning these parameters will give higher precision and quality in injection molded parts including pattern injection speeds.

Clamping Unit

The clamping unit is a critical part of the injection molding machine, it holds the mold closed during the injection phase. This unit applies the necessary clamping force to keep the mold halves together, preventing molten plastic from leaking out during the injection process. The clamping unit can use hydraulic or toggle systems to achieve this clamping force.

Getting the correct clamping force is important to produce high quality molded parts. Not enough clamping force will cause defects like flash where plastic escapes from the mold cavity. Too much clamping force will damage the mold or the machine itself.

So we need to calculate the total clamp force based on the projected area of the part and the material used. Proper clamping force will keep the mold closed and the parts formed correctly.

Mold

The mold is what gives the plastic parts their shape and size. Custom plastic injection molds are critical in the injection molding process as they directly impact the quality and precision of the products. Molds are made from steel or aluminum molds with electrical discharge machining (EDM) being used to create complex mold designs due to its precision and speed.

Pre hardened steel is used for lower volume or larger molds as it's cost effective but has less wear resistance than fully hardened steel. Hardened steel molds are heat treated after machining to increase wear resistance and extend life. Typical hardness for pre hardened steel is 28-38 HRC and fully hardened steel is 50-60 HRC so you can guide material selection based on durability and application.

The mold design is key to the success of the injection molding process. Consider:

- Mold temperature

- Cooling channels

- Ejector pin placement These must be thought through so the parts are properly formed and can be easily ejected from the mold.

Optimizing the mold design gives you more control over product quality, reduces cycle time and increases production efficiency. Mold maintenance and regular inspections are also crucial to extend the life of the mold and ensure consistency.

The Injection Molding Process

The injection molding process is a series of steps that turn plastic pellets into finished products. Injection molding is one of the most common ways to shape and make plastic parts. This process involves melting the plastic, injecting it into a mold and letting it cool and solidify before ejection. Each step in the process plays a big role in the quality and precision of the final molded parts.

Understanding and optimizing these steps means high efficiency and consistency in production time.

Material Preparation

Material preparation is the first step in the injection molding process where plastic materials are selected and prepared for molding. Various parameters such as thermal stability and viscosity must be considered when choosing the right plastic material for a specific application. For example, semi crystalline materials like polypropylene have different processing and foaming behavior compared to amorphous polymers which affects their suitability for certain applications.

Understanding the mechanical properties of the chosen plastic is key to ensuring the final part meets strength and durability requirements. Polypropylene for instance is good because of its low viscosity and high availability making it a popular choice for many injection molding applications.

The material is fed into the injection molding machine through a hopper where it is prepared for melting. A screw type plunger pushes the plastic forward ensuring a consistent flow of material during the molding process.

Proper material preparation is critical to getting high quality molded parts as it ensures the plastic flows smoothly through the machine and into the mold cavity. Controlling the material's temperature and viscosity also helps prevent defects and improves overall production efficiency especially when avoiding contaminated material.

Injection Phase

During injection:

- Melted plastic is pushed through the nozzle into the mold cavity.

- This is the critical phase as it determines how well the plastic fills the mold and forms the desired shape.

- The injection unit's screw pushes the melted plastic through the nozzle for a smooth and consistent flow into the mold cavity.

- Injection speed and pressure must be correct to avoid air bubbles or incomplete filling.

Design considerations like parting lines play a big role in the injection phase. Placing parting lines strategically helps the flow of molten plastic and allows air to escape easily during injection especially when dealing with a plastic part.

By adjusting injection speed and pressure, manufacturers can achieve higher precision and quality of their molded parts. This phase requires close monitoring and adjustments to ensure the plastic flows evenly and fills the mold completely.

Cooling and Ejection

Once the mold is filled with molten plastic, the cooling process begins:

- The mold is held at a set temperature to ensure consistent cooling and solidification of the plastic.

- Proper cooling is key to prevent warping or shrinkage which can happen if the plastic cools unevenly.

- Cooling time can impact cycle time and overall efficiency of the injection molding process.

- Some areas of the mold, like beryllium copper, are designed to remove the most shear heat generated during the molding process which improves cooling.

Once the part is cool enough, ejector pins are used to remove the part from the mold. The ejection phase must be managed carefully to not damage the part or the mold. Temperature and timing is critical to ensure the part is fully solidified and can be ejected without deformation.

By optimizing the cooling and ejection phase, manufacturers can get better quality and consistency in parts that need fast heat removal, reduce shear heat generated and overall production efficiency.

Mold Temperature Control: Ensuring Consistency and Quality

Mold temperature control is key to a successful injection molding process. The mold temperature directly affects how the molten plastic flows into the mold cavity and the consistency, surface finish and structural integrity of the molded parts. Each plastic material has an optimal mold temperature range – typically 50-150°C – so temperature control is crucial to get the best results.

A stable mold temperature ensures the molten plastic fills the mold cavity evenly, reducing the risk of warping, sinking and uneven surfaces. Inconsistent mold temperature can cause variations in cooling rates which can cause internal stresses or dimensional inaccuracies in the final product.

To achieve optimal temperature control manufacturers often use a combination of heating and cooling systems such as water channels, oil heaters or electric cartridge heaters in the mold. Insulation around the mold and temperature sensors further enhance control allowing for real time adjustments during the molding process. By controlling the mold temperature manufacturers can produce high quality molded parts and minimize rework or scrap.

Advanced Injection Molding Techniques

New injection molding techniques for complex and high performance plastic parts to get molded products. These techniques focus on product quality and production efficiency by using new materials and processes. New techniques use existing materials and blends to get a wider range of properties and performance in molded parts.

By using these new methods you can make parts with intricate features, different colors and properties. This section will cover some of the most popular new injection molding techniques and their benefits.

Multicomponent Injection

Multicomponent injection molding is a process that allows you to make parts with multiple colors or materials in one shot. This involves injecting different plastics into the mold sequentially or simultaneously to create parts with different properties or aesthetics. This is useful for parts that need different functions or appearances, like grips with soft-touch surfaces or components with built-in seals.

The benefits of multicomponent injection molding are reduced assembly time, improved product quality and more design flexibility. By combining different materials and colors in one molding cycle you can achieve complex designs and enhance the functionality of the parts. This also allows to integrate multiple features in one part and reduce secondary operations and increase production efficiency.

Gas-Assisted Injection Molding

Gas assisted injection molding is a technique where gas is injected along with the plastic to create hollow sections in the molded parts. This has several benefits:

- Controlled filling

- Uniform plastic distribution

- Less deformation and shrinkage By optimising the filling process gas assisted molding reduces the weight of the parts and improves the overall quality.

One of the application of gas assisted injection molding is in the production of plastic disk holders for optical readers. This allows for more design freedom and flexibility to produce parts with complex geometry and less material usage.

By combining gas assisted molding with other advanced techniques like microcell injection molding, you can get even more improvement in product quality and performance.

Microinjection Molding

Microinjection molding is a technique used to make very small and precise plastic parts. Low cost, short cycle times and high precision for small parts. The demand for microdetails has driven the development of microinjection molding technologies so it's a popular choice for medical devices and electronics.

One of the benefits of microinjection molding is the ability to make parts with tight tolerances and fine details. But rapid cooling can create a thin layer which can be a challenge in the molding process.

Proper design considerations such as wall angle is key to ensure parts can be easily ejected from the mold and maintain their dimensions. By optimizing the microinjection molding process you can get high quality, miniaturized parts with high precision and reliability.

Custom Plastic Injection Molding

Custom plastic injection molding is the way to go when you need unique or specialized plastic parts. Unlike standard molds, custom plastic injection molds are designed and built to your specifications so you can produce parts with complex geometries, tailored wall thickness and exact material properties.

The process starts with a design phase where engineers consider the intended use of the plastic part, the optimal wall thickness for strength and manufacturability and the best plastic material for the application. Then a prototype is created – often using rapid prototyping techniques – to validate the design and make any necessary changes before full production.

Once the design is finalized the tooling phase involves building the custom mold – usually from steel or aluminum – to ensure longevity and accuracy. During production molten plastic is injected into the custom mold to produce the plastic parts to exact specifications.

Custom plastic injection molding offers flexibility, high repeatability and the ability to produce parts that standard injection molds can't. It's perfect for industries that require specialized components from automotive to medical devices.

Data-Driven Optimization for Improved Efficiency

In today's manufacturing world data driven optimization is changing the injection molding process. By collecting and analyzing data from sensors and production systems you can gain valuable insights into key parameters such as injection pressure, mold temperature, injection speed, cool time and cycle time.

Monitoring these data points will show trends and patterns that may indicate inefficiencies or potential quality issues. For example by analyzing injection pressure and mold temperature data you can find the optimal settings for consistent part quality and reduced cycle times. Adjustments based on real time data will give you fewer defects, higher yields and less material waste.

Data driven optimization not only improves product quality but also productivity and reduces operational costs. By using advanced analytics and process monitoring you can make informed decisions that drive continuous improvement in your injection molding operation.

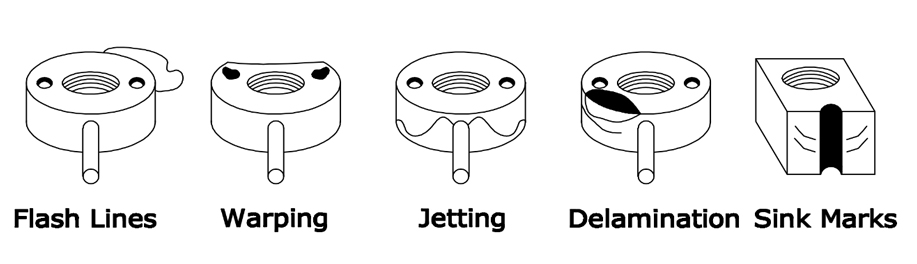

Common Defects and Troubleshooting in Injection Molding

Despite the precision of the injection molding process, defects can still occur and affect the quality and functionality of the molded parts. Here are some common defects:

- Sink marks

- Warpage

- Flash Each is caused by different factors during the molding process. Fixing these defects is key to high product quality and minimizing waste.

This section will go through the causes of these defects and provide tips to help manufacturers get the best results.

Sink Marks

Sink marks are depressions that form on the surface of a molded part when the inner material cools and shrinks faster than the outer sections. This defect usually means uneven cooling during the injection molding process. To prevent sink marks, designers can use rib patterns to strengthen the part and avoid solid sections that shrink. Reducing wall thickness can also help minimize sink marks as thinner sections cool more evenly.

Implementing these design changes will give more consistent cooling and less sink marks. To get better quality molded parts, try:

- Proper cooling channels

- Uniform wall thickness throughout the part

- Monitor and adjust the injection molding process to prevent sink marks and high product quality.

Warpage

Warpage occurs when parts warp due to uneven cooling and internal stresses that cause the part to bend or twist. This is often caused by inconsistent mold temperature or material shrinkage. Proper temperature control during injection molding is key to preventing warpage as it ensures even cooling and reduces internal stresses.

To fix warpage manufacturers should focus on optimizing the cooling channels and ensuring even heat distribution in the mold. Adjusting the injection speeds and pressures can also help with even cooling and warpage. Manage these properly and you get high quality parts with minimal deformation and better dimensional stability.

Flash

Flash is unwanted material that forms at the parting lines of injection molded parts and affects their quality. This can happen due to high injection pressure or misaligned mold, allowing plastic to escape the mold cavity. The gate size in the injection molding system is key to controlling flash.

To minimize flash:

- Adjust gate size to balance injection speed and pressure.

- Use bigger gates to allow for faster resin flow, reduce mold time and minimize flash.

- Ensure proper mold alignment.

- Keep consistent clamping force to prevent flash and get high quality parts.

Best Practices for Mold Design

Mold design is key to optimizing the injection molding process and getting great parts. By following best practices in mold design you can reduce defects, increase production efficiency and get better parts.

This section covers the key considerations in mold design, including gate and runner systems, wall thickness and parting lines.

Gate and Runner System

The gate and runner system is where the molten plastic goes into the mold cavity. The design of the gates and runners is critical to get uniform material flow and no defects. Injection molding has two types of gates. These are manually trimmed gates and automatically trimmed gates. Manually trimmed gates require an operator to separate parts from the runners, while automatically trimmed gates are designed to separate during the molding process.

Edge gates are the most common gate design used in injection molding and is best for flat parts. The size and shape of the gates are determined by the plastic type, gate temperature and part dimensions to get uniform material flow.

Optimizing the gate and runner system gives you more control over the injection process, reduces defects like flash and gets you better parts.

Wall Thickness

Uniform wall thickness is key to reducing cycle times and part quality. Typical wall thickness for injection molded parts is 2mm to 4mm (0.080” to 0.160”). Inconsistent wall thickness during cool down can cause warping, twisting or cracking of the parts especially when parts are not the same thickness.

When designing parts make sure bosses and ribs don't exceed 60% of the nominal wall thickness to maintain structural integrity. Optimizing wall thickness and uniformity throughout the part will give you better quality and consistency in molded parts.

Proper design and monitoring of the process is key to uniform wall thickness and no defects.

Parting Lines

Parting lines are the lines of separation where the two halves of the mold meet. They play a big role in shaping molded parts. Parting lines are a design and manufacturing challenge as they affect both aesthetic and mechanical considerations in molded parts. Every injection molded part has parting lines, you can't avoid them but you can strategically place them for successful molding.

Proper parting line placement can help minimize defects like flash and overall part quality. Designers should consider the parting line's impact to the part's appearance and functionality, make sure it doesn't interfere with critical features or create weak points.

Careful planning of parting line placement gives you more control over the molding process and results to high quality parts with minimal defects.

Environmental Considerations in Injection Molding

Injection molding has a big environmental impact - waste, resource depletion and greenhouse gas emissions. But by adopting sustainable practices and using eco-friendly materials manufacturers can reduce their footprint.

This section looks at ways to make injection molding more sustainable, focusing on sustainable materials and energy efficiency.

Sustainable Materials

Post consumer recycled plastic is on the increase, some manufacturers are using at least 40% recycled material in their products without compromising quality. Recycling plastic scrap from injection molding can reduce waste, materials like sprues can be reprocessed and reused. Sustainable injection molding materials can replace conventional plastics, using biopolymers and wood from industrial side streams.

Using recycled and eco-friendly materials reduces the environmental impact of the injection molding process. The industry is moving towards more sustainable practices, reducing waste and resource consumption. It's good for the planet and good for the company's reputation and to appeal to environmentally conscious consumers.

Energy Efficiency

Energy saving is key in injection molding as it reduces costs and environmental impact. Using materials like PLA which require less energy in the injection molding process can give huge energy savings compared to traditional methods. Optimizing mold temperature is key to energy efficiency as it ensures consistent material flow and reduces heat loss.

Reducing cycle times not only speeds up production but also reduces energy consumption by reducing overall processing time. Focusing on process optimization and energy saving practices gives more sustainable production and a smaller environmental footprint. These will give a more eco friendly and cost effective injection molding process.

Conclusion

In short, optimizing your injection molding process is about understanding the machine, the process and the techniques. By addressing the common defects and best practices in mold design, you can achieve better quality and efficiency. Environmental considerations like using sustainable materials and energy efficiency are also key to reducing the environmental impact of injection molding.

By following the tips and tricks in this guide, you can improve your injection molding, get better products, less waste and more sustainability. The journey to mastering injection molding is continuous, you need to keep learning and adapting. With the right knowledge and approach, you can be excellent in your injection molding and contribute to a more sustainable and efficient industry.