Introduction

GD&T (Geometric Dimensioning and Tolerancing) defines a part's geometry and tolerances. It makes parts fit and function in assemblies. This article covers the basics, benefits and uses of GD&T.

Summary

- GD&T (Geometric Dimensioning and Tolerancing) is a must have tool for defining precise geometric requirements in engineering drawings so everyone involved in manufacturing and inspection can communicate seamlessly.

- From its inception in 1938 to the establishment of formal standards GD&T has changed manufacturing processes and ensured quality production and adherence to design specifications.

- To implement GD&T effectively you need to understand tolerance types and challenges so training and communication is required to avoid ambiguity and ensure all parts fit together in assembly.

Understanding GD&T

Geometric Dimensioning and Tolerancing (GD&T) is more than just a set of symbols; it's a language engineers use to describe the exact geometry of a part, often on an engineering drawing. The purpose of GD&T in technical drawings is to define the geometric characteristics and tolerances a part must meet during manufacture. So everyone from designers and manufacturers to quality inspectors know exactly what the part must be. Better communication and collaboration.

Proper use of GD&T helps the manufacturing process by guiding material selection, inspection and parts fitting together as designed. GD&T is critical when part features are functional or interchangeable, when functional gaging is required and when datum references are needed. GD&T describes design intent not just geometry, simplifies complex features and ensures parts meet their functional requirements.

Originally GD&T was meant to describe the designer's intent about the part's dimensions and tolerances not set an inspection standard. Over time it has become a tool to ensure high quality, reliable manufacturing that meets exact specifications. This saves time and increases efficiency.

In summary GD&T is for defining product geometry and tolerances so every part meets its design intent.

Key Benefits of Using GD&T

One of the biggest benefits of GD&T is the communication between engineers and manufacturers. GD&T is a universal language that defines the geometric characteristics and tolerances of parts so everyone in the process knows exactly what's required. This means less errors and misunderstandings.

GD&T saves time and cost in:

- Reducing waste and minimizing design-manufacturing-test fit cycles so parts are more likely to fit first time and save resources.

- Material selection based on machinability to cut costs.

- Quality control with precision and clarity to reduce rejects and ensure parts meet specs.

Another big benefit of GD&T is ensuring part function and interchangeability. GD&T aligns design specs with manufacturing capability so parts fit and function as intended in final assembly. This is critical in industries where part interchangeability is key like aerospace and automotive.

Overall proper GD&T provides a framework for parts to be made to the highest precision and quality.

GD&T Symbols and Definitions

| Symbol for | Control Type | GD&T Symbols (ASME Y14.5) | GD&T Symbols (ISO) | Description |

|---|---|---|---|---|

| Flatness | Form | ▱ | ▱ | Used to specify the most protruded part and the most concaved part. |

| Roundness | Form | ○ | ○ | Used to specify how close a target should be to a perfect circle. |

| Cylindricity | Form | ⌭ | ⌭ | Used to specify how straight a target is and how close the target should be to a perfect circle. |

| Profile tolerance of line | Profile | ⌒ | ⌒ | Used to specify how close a curvature (cross-section) is to the design. |

| Profile tolerance of plane | Profile | ⌓ | ⌓ | Used to specify how close a curvature (surface) is to the design. |

| Parallelism | Orientation | // | // | Used to specify how accurately parallel two lines or planes are to the datum. |

| Perpendicularity | Orientation | ⟂ | ⟂ | Used to specify how accurately perpendicular a target is to the datum. |

| Angularity | Orientation | ∠ | ∠ | Used to specify how accurately angled a target is to the datum. |

| True position | Location | ⌖ | ⌖ | Used to specify how accurately a target is positioned in relation to the datum. |

| Concentricity | Location | Centres of two objects with a clearly defined centre must be at the same location. | ||

| Symmetricity | Location | Used to specify how symmetrical a target is to the datum. | ||

| Circular runout | Runout | Used to specify the run-out of any part of a circumference when a target is rotated. | ||

| Total runout | Runout | Used to specify the run-out of the entire surface when a target is rotated. | ||

| Datum target | ⌀2 A1 | ⌀2 A1 | Point, line or zone for establishing a datum. | |

| Datum indication | Location |

A

A

|

A

A

|

Datum position. |

| Straightness | Form | ━ | ━ | Used to specify how straight a target is. |

| Toleranced feature | Indication of symbols, tolerances, types of geometric tolerances, position and other requirements. | |||

| Profile tolerance (entirety) | Means to apply geometric tolerance to the entirety of the feature indicated by an arrow. | |||

| Profile tolerance (perimeter) | Means to apply geometric tolerance to the perimeter of the feature indicated by an arrow | |||

| Continuous feature | CF | CF | “CF” stands for “continuous feature.” This requirement is indicated when features need to be geometrically treated as a single feature. | |

| Spot facing | ⌴ SF | ⌴ SF | Machining that creates a counterbore enlarges another coaxial hole. | |

| Common tolerance zone | CZ | CZ | “CZ” stands for common zone. Indication that multiple features in separated positions are deemed as a single tolerance zone. | |

| Basic Dimension | 50 | 50 | Theoretically exact dimension (TED) | |

| Unequally disposed profile tolerance | Ⓤ | Ⓤ | “U” stands for “unequally disposed profile.” This specifies the range of run-out of the offset amount from the tolerance zone (tolerance zone limit) in terms of the profile tolerance of a plane. “UZ” is used for annotation according to the ISO standards. | |

| Indication of tangent plane | Ⓣ | Ⓣ | “T” stands for “tangent plane.” How angled a plane in contact with the surface is to the datum plane within the range of specified surface is indicated by parallelism. Unlike parallelism, this specifies the convex of the surface and not the concave. | |

| Envelope Requirement | Ⓔ | Ⓔ | “E” stands for “envelope.” This symbol indicates the mutual dependency of size tolerance and geometric tolerance. It specifies the envelope of perfect form. | |

| Application of least material condition | Ⓛ | Ⓛ | “L” stands for “least material condition.” This symbol indicates the application of least material condition. | |

| No material requirement | Ⓢ | Ⓢ | Symbol used by ANSI standard. It represents “Regardless of Feature Size (RFS).” This symbol has been removed in ASME Y14.5-2009. | |

| Indication of projected tolerance zone | Ⓟ | Ⓟ | “P” stands for “projected tolerance zone.” This symbol indicates the tolerance applied to the protrusion of a feature. | |

| Application of maximum material condition | Ⓜ | Ⓜ | “M” stands for “maximum material condition.” This symbol indicates the application of maximum material condition. | |

| Free state of non-rigid parts | Ⓕ | Ⓕ | “F” stands for “free state.” This symbol indicates a deformation beyond size tolerance or geometric tolerance under a free state. | |

| Statistical tolerance | ST | ST | Specification that assigns tolerance to the assembled components according to statistics. By applying statistical tolerance, the tolerance for each component can be increased, reducing the clearance between the components and the mating parts. While this can improve product performance and/or reduce production costs, the application of this tolerance requires appropriate statistical process management as a prerequisite. | |

| Dimension Origin | ⌖ | ⌖ | The dimension origin symbol is used in Geometric Dimensioning and Tolerancing to indicate where a dimension must be measured from. | |

| Counterbore | ⌴ | ⌴ | The counterbore symbol is used on a drawing to indicate that a counterbore hole feature is required. A counterbore is a flat-bottomed cylindrical hole that is larger than and coaxial to another cylindrical hole. | |

| Countersink | ⌵ | ⌵ | The countersink symbol is used to indicate that a countersink hole feature is required. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. | |

| Depth | The depth symbol is used to indicate a measurement from the bottom of a feature to the outer surface of a part. The depth symbol is commonly used for holes, but can be used on other features as well, such as slots or counterbores. | |||

| Between | To indicate that a profile tolerance applies to several contiguous features, letters may designate where the profile tolerance begins and ends | |||

| Target Point | X | X | A datum target is a point, line or limited zone on a target with which machines and instruments for processing, measuring and inspection come into contact in order to establish a datum. | |

| Conical Taper | The conical taper symbol is placed with a dimension value to indicate that the value is controlled as a standard taper. The value listed with the symbol is the ratio of the diameter change to length change. | |||

| Slope | The slope modifying symbol is placed with a value to indicate that this value is controlled as a slope or a “flat taper.” The value listed with the symbol is the ratio of the height change to length change. | |||

| Square | The Square symbol is used to indicate a square feature on a drawing. It is a symbol that many people are not aware of, but it is useful to reduce the number of required dimensions for a feature. | |||

| Diameter | ⌀ | ⌀ | The diameter symbol is used to indicate that the size of a circular feature is being dimensioned using the diameter of that feature. The diameter symbol can only be used on circular features that are greater than 180 degrees. | |

| Radius | R | R | The Radius symbol is used to indicate that the size of a circular feature is being dimensioned using the radius length, which is half of the diameter length. | |

| Spherical Radius | SR | SR | The Spherical Radius symbol is a variant of the Radius symbol, with the letter “S” placed in front of the Radius symbol. The Spherical Radius symbol is used to indicate the radius of a spherical, rather than circular, feature. | |

| Spherical Diameter | ⌀S | ⌀S | The Spherical Diameter symbol is a variant of the Diameter symbol, with the letter “S” placed in front of the Diameter symbol. The Spherical Diameter symbol indicates that the feature being dimensioned is spherical, rather than circular. | |

| Controlled Radius | CR | The Controlled Radius is a variation of Radius. It dimensions the size of a circular feature using the radius length, but it also gives an additional requirement – that the surface of the contour must be a “fair” curve. This means that the surface must be continuous, without reversals. | ||

| Basic Dimension |

77

|

77

|

Basic Dimensions are essentially the perfect target you are trying to hit without the tolerance on the dimension itself. They do not have tolerances by themselves – therefore, they must be accompanied by a geometric tolerance if they are specifying the size, location orientation or form of a feature. | |

| Reference Dimension | (77) | (77) | A numerical value enclosed in parentheses, provided for information only. They do not drive for production and inspection. | |

| Places | 5X | 5X | Represents number of places. |

Table: GD&T Symbols and Definitions

Types of Tolerances in GD&T

GD&T breaks down tolerances into four main categories:

- Form

- Orientation

- Location

- Runout

Each one serves a purpose in controlling the geometric characteristics of parts to meet their functional requirements.

Understanding these types of engineering tolerances is key to applying GD&T in manufacturing and inspection.

Form Controls

Form controls are used to ensure surfaces and features meet their desired form and function. For example, straightness tolerance is used to ensure an element is a straight line, which is important for parts that need to slide or seal. The tolerance zone for straightness is the space between two parallel lines where the feature must lie within the form tolerance.

Flatness tolerance is another form control used to ensure a surface or median plane lies between two parallel planes. This is important for parts that need to mate with a flat surface, like gaskets or surface plates.

Applying form controls allows manufacturers to hold critical specifications and have control over parts that function correctly in their intended application through statistical process control.

Orientation Controls

Orientation controls in GD&T are:

- Angularity: The condition of a surface or feature at a specific angle to a datum. Critical for assembly alignment.

- Parallelism

- Perpendicularity

These controls ensure features and surfaces are in relation to each other in a specific way.

Parallelism means a feature axis is equidistant to a datum plane along its length. Perpendicularity means a surface or feature is at right angles to a datum. Critical for parts that must fit together precisely.

Controlling orientation with GD&T means parts meet design intent and work as intended in the end application.

Location Controls

Location controls define the allowable movement of feature locations relative to datum references so features are properly placed in assemblies. Position tolerance, represented by a crosshair symbol, is a cylindrical or spherical tolerance zone aligned with the datum feature's axis so features are precisely placed including true position.

Concentricity is another location control that ensures the median points of surfaces are aligned to a datum axis and a feature axis so surfaces are uniform about an axis. This is critical for components like shafts and bearings where proper alignment is key to smooth operation and minimizing vibration.

Location controls allow manufacturers to ensure parts meet functional requirements and fit together.

Runout Controls

Runout controls surface variations to ensure precision in rotating parts.

Circular runout:

- Controls the circular elements of a surface

- Applies the tolerance independently at each circular measuring position

- Ensures each element of the surface meets the requirements.

Total runout controls all surface elements, the tolerance is applied to all circular and profile measuring positions as the part is rotated 360° about the datum axis. This control ensures the entire surface meets geometric requirements, reduces production costs and improves quality control.

Datums and Datum Features

Datums are theoretical reference points or planes used for measuring other features during inspection. They are the foundation for dimensional tolerances and define the datum reference frame that all other features are referenced to. The selection of datum features is based on the functional requirements of the part and how it will perform and align.

A datum feature is a physical feature on a part that is used to establish a DRF. The DRF is three mutually perpendicular intersecting datum planes that define the coordinate system in which all other dimensions and tolerances are specified. This constrains all six degrees of freedom so parts can be accurately manufactured and inspected.

Choosing stable and accessible datum features is key to minimizing measurement errors and improving repeatability. The roles of datum features are:

- Primary datum: typically restricts 3 degrees of freedom

- Secondary datum: constrains 2 degrees of freedom

- Tertiary datum: restricts the last degree of freedom

Selecting and defining datum features and individual features ensures parts meet design intent and specific features work as intended in their application.

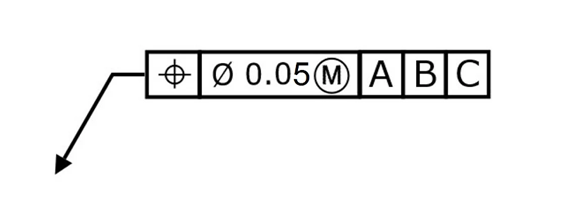

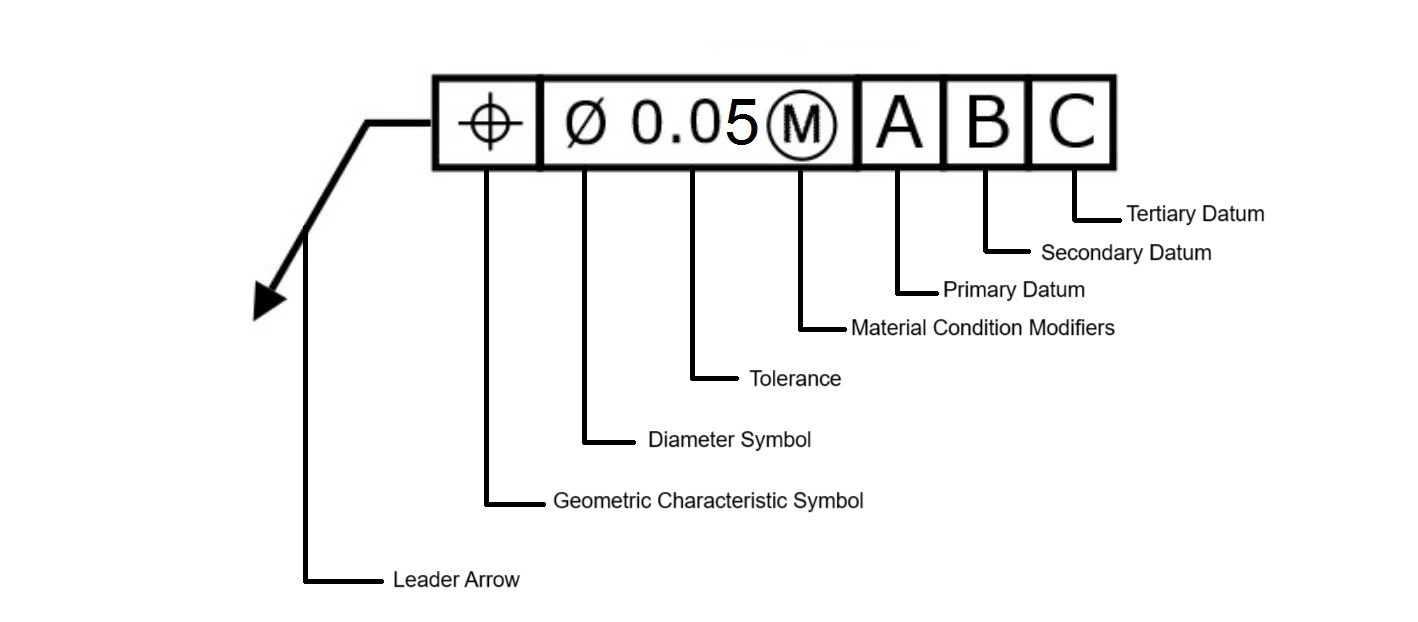

Feature Control Frames

Feature control frames are used to define the conditions and tolerances of geometric controls. They show the specifications for a part's geometric control including the GD&T symbol, tolerance zone shape and datum references when required.

This ensures all geometric characteristics and geometric tolerancing is clearly communicated and understood.

First Compartment

The first compartment of a feature control frame is the key to communicating geometric requirements. It's designed to house one geometric characteristic symbol so geometric tolerancing is clear and precise including a circular feature.

Second Compartment

The second compartment of the feature control frame shows the tolerance zone type and dimensions and the tolerance value. The tolerance value must always be a numerical value so the tolerance zone is clearly defined and understood.

Final Compartments

The final compartments show datum feature references if required to give guidance for inspection and manufacturing processes. These compartments ensure part alignment and measurement by showing primary, secondary and tertiary datum references as required.

Material Condition Modifiers

Material condition modifiers in GD&T indicate that a tolerance applies at a specific feature size, specifically Maximum Material Condition (MMC) or Least Material Condition (LMC):

- MMC means the feature has the most material.

- For external features, MMC is the largest.

- For internal features, MMC is the smallest.

When features are toleranced at MMC, they get extra ‘bonus' tolerances as the feature gets smaller towards LMC. LMC means the smallest size for external features and the largest size for internal features, so minimal material present.

Material condition modifiers are key to communicating the intent of tolerances based on feature size so parts are manufactured and inspected to the desired geometric specifications.

GD&T Inspection Techniques

GD&T inspection techniques are key to ensuring engineered parts meet the specified geometrical tolerances and engineering dimensions in mechanical engineering. Variable gages like calipers and coordinate measurement machines are versatile tools used to measure all sorts of feature sizes and tolerances in GD&T inspection. These tools give you accurate measurements so parts meet their design specs.

Fixed gages like pin and plug gages are designed to measure specific features in a go/no-go format so you get accuracy in inspection. These gages are important to verify parts meet their tolerances, a simple and effective way to quality control. And datum feature simulators are critical tools used during inspection to hold parts in the correct orientation, simulating the ideal geometry of the datum features.

Using these inspection techniques ensures parts meet GD&T specs, maintains design integrity and function in final application. These techniques are important in quality control to identify and correct deviations from specified tolerances.

GD&T Challenges

Implementing GD&T can be tricky because of different interpretations and lack of understanding among team members. To overcome these challenges organizations need to invest in training, develop clear standards and encourage team communication. So everyone in the production process understands GD&T and can apply it correctly.

Tolerance accumulation can cause parts not to fit together during assembly. This happens when multiple tolerances add up and you get a bigger deviation from the design. Tolerance accumulation needs to be planned and controlled during design and manufacturing to ensure all parts fit together as intended even with looser tolerances and bonus tolerance.

Manufacturers are also turning to additive manufacturing (AM) to solve supply chain and manufacturing challenges, so they need robust GD&T frameworks for AM. Adapting GD&T for AM means developing standards that address the dimensional variability and anisotropic properties of additive processes. By addressing these challenges manufacturers can implement GD&T correctly and ensure parts meet the design and function correctly in end use.

Conclusion

Geometric Dimensioning and Tolerancing (GD&T) provides a standardized framework in manufacturing toward precision, efficiency with communication. For engineers and manufacturers, assurance that parts meet the design intent along with working as intended is found by understanding the basics in addition to benefits and practical applications. Collaboration plus training is needed for GD&T implementation. Also required is a comprehension of the principles. With GD&T, it is possible to dream of perfect precision and also to communicate smoothly in engineering as a reality.

FAQs about Geometric Dimensioning and Tolerancing

What is GD&T?

GD&T or Geometric Dimensioning and Tolerancing is a standardized system of symbols that communicates the specs to the production team. It's clarity and precision in engineering.

Who developed the GD&T system and when?

The GD&T system was developed by Stanley Parker in 1938.

What are Material Condition Modifiers in GD&T?

Material Condition Modifiers in GD&T indicate a feature's size constraints, expressing its condition as maximum material condition (MMC), least material condition (LMC) or regardless of feature size (RFS). These modifiers help define tolerance zones based on the feature's material state.

What is a basic dimension in GD&T?

A basic dimension is a theoretically exact measurement that defines the ideal geometry of a manufactured part, ensuring precision in design specifications. This clarity helps maintain the intended design quality throughout production.

What is the main advantage of using GD&T over traditional dimensioning methods?

The main advantage of using GD&T over traditional dimensioning methods is its ability to ensure proper fit of mating parts while providing a universal language for effective communication among engineers and manufacturers. This enhances clarity and precision in the design process.