Introduction

CNC precision machining uses computer controlled tools to make highly accurate and complex parts for industries like aerospace, medical and automotive. In this guide you'll learn how it works, the benefits and the applications.

Summary

- CNC precision machining is an advanced manufacturing process that uses computer-controlled systems to achieve high accuracy and tight tolerances in part production.

- CAD and CAM integration allows design and automation of machining operations, reducing errors and ensuring consistency in manufacturing.

- CNC precision machining serves automotive, medical and aerospace industries by making complex parts that meet quality and safety standards.

Understanding CNC Precision Machining

CNC machining is not just a process, it's a dance of technology, skill and innovation. This process uses computer-controlled systems to produce highly accurate and complex parts from various raw materials. At the heart of CNC machining are computer programs which control the machining process. Whether one machine or multiple machines working together, the goal is the same: tight tolerances and accuracy.

To understand CNC machining you need to look at the processes, equipment, materials and the principles behind this advanced manufacturing technique. Standard machining methods just don't cut it when it comes to producing parts that require the highest level of precision. A machinist, the skilled person who operates the CNC machine, reads the blueprints and ensures precision in manufacturing. Critical applications from automotive to medical implants rely on precision machining and CNC machining.

What is CNC Precision Machining?

In a nutshell, CNC precision machining is a subtractive manufacturing process that cuts and shapes raw materials using computer-controlled machine tools. Unlike manual machining, precision CNC machining automates most of the process so you get consistent quality and accuracy.

This is key in industries where tight tolerances and complex geometries are critical. Using CNC systems, this process automates material removal based on digital designs for exceptional precision and repeatability.

The move from manual to highly automated has changed the role for precision machining.

The Role of CAD and CAM in Precision Machining

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) are the two cornerstones of precision CNC machining. CAD software lets engineers create detailed and accurate digital models of physical parts, build, modify, analyse and optimise designs before any physical prototyping, including CNC.

Once the CAD model is complete, CAM takes over, converting those digital designs into tool movement instructions for the CNC machines. This integration ensures the final product matches the original design exactly, minimises errors and maximises precision and efficiency.

CNC Programming and Setup

CNC programming is the core of the precision machining process. It's writing G&M codes that the CNC machines run to do the machining. The CNC operator sets up the machine, configures the parameters like spindle speed, depth and feed rate to get the best performance.

Proper setup, selecting the right tools and holding the workpiece securely is key to a successful CNC machining job. Proper tooling, using special fixtures and setup processes is required to get accurate and repeatable results in CNC precision machining.

During machining, the machine follows the programmed instructions to do the operations on the material and gets the final product with the machine.

Types of CNC Precision Machines

The world of CNC machining is big and there are many machines to suit different manufacturing needs. From milling machines to lathes and electrical discharge machines (EDMs), each type of CNC machine has its own capabilities. Machinists also use equipment like drill presses, drill bits and grinders for tasks like drilling, hole making and surface finishing.

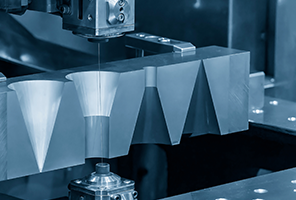

CNC Milling Machines

CNC milling machines are good at reshaping stationary materials with rotating cutting tools. They are good at making flat surfaces, shallow and deep cavities and complex geometries like threads and slots. Typical applications are making square and rectangular components from flat and plane workpieces.

The spindle of a CNC milling machine can be horizontal or vertical, some machines can do both. This versatility makes CNC milling machines a must-have for manufacturing many complex parts.

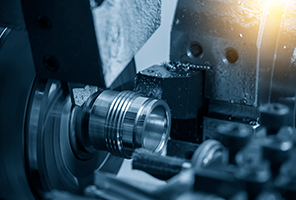

CNC Lathes and Turning Machines

CNC lathes turn raw material with a rotating cutting tool and stationary cutting tools. This is great for making cylindrical parts and lathe shapes.

CNC lathes have fewer axes than milling machines and are more compact and efficient. An advanced version called Swiss machining allows for linear movement for more complex machining.

Electrical Discharge Machines (EDM)

Electrical Discharge Machining (EDM) is a non-contact process that uses electrical sparks to cut material with precision. This is great for machining hard metals and making complex shapes that are hard to do with traditional methods.

EDM's ability to remove material with precision makes it a must-have in industries that require high accuracy and complex geometries like aerospace and medical device manufacturing.

Key Materials in CNC Precision Machining

Material selection in CNC precision machining is key as different materials have different properties and benefits. Metals and plastics are the two main materials used, each with their own advantages. Heat sinks are a common electronic component made through CNC precision machining, great for dissipating heat in electronic devices.

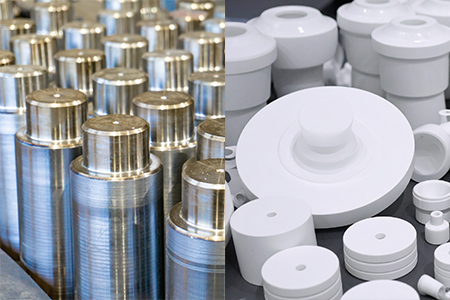

Metals

Metals like aluminum, stainless steel, brass, copper and titanium are the common types used in CNC precision machining. Aluminum—especially 6061 and 7075—is lightweight and machinable. Stainless steel—especially SS304 and SS316—is strong and corrosion-resistant, making it good for many applications.

Electrical Discharge Machining (EDM) is very effective in working with hard metals and alloys like titanium and tungsten, to create complex and precise components.

Plastics

Plastics like polycarbonate and ABS are also used in CNC precision machining. They are flexible and have high accuracy, so they're great for prototyping and finished products.

Using plastics in CNC machining allows for parts with smooth finishes and precise dimensions, which is especially required in the medical devices and electronics industries.

CNC Precision Machining Benefits

CNC precision machining has many benefits—from high accuracy and efficiency to versatility across industries including CNC machines and CNC equipment.

That's why it's the preferred choice for complex and high precision parts.

High Accuracy and Tight Tolerances

One of the biggest benefits of precision CNC machining is the ability to hold tight tolerances, sometimes as close as +/-0.0002 inches. This means components fit together perfectly and the final product works as intended.

CNC machines are designed to produce consistent, repeatable results—with no human error and high quality across runs.

Efficiency and Cost Savings

CNC precision machining speeds up production and efficiency. It uses less material and creates fewer defects, reducing costs and waste.

Plus, with high automation in CNC machining, it can meet increasing production demands, maintain quality and reduce labor costs.

Versatility Across Industries

CNC precision machining is very versatile and serves many industries such as automotive, aerospace and medical. Its ability to produce complex and high precision parts makes it essential across many sectors, meeting the unique requirements of each industry.

CNC precision machining is adaptable, can handle different materials and applications and makes it a valuable asset in today's manufacturing.

CNC Machine Maintenance and Repair

Proper maintenance and timely repair of CNC machines is key to maintaining high precision CNC machining. Regular maintenance of CNC equipment not only extends the life of the equipment but also ensures every part machined meets spec. Maintenance routines include lubricating moving parts, inspecting and replacing worn out cutting tools and updating software and firmware that controls the machines. This prevents unexpected breakdowns and supports the tight tolerances required in modern manufacturing.

When issues do arise, skilled technicians with CNC machining and machine tool knowledge are critical to diagnosing and repairing complex equipment. They ensure repairs are done quickly and get production back on track. By doing both preventive maintenance and expert repair, manufacturers can reduce costs, avoid mistakes and deliver high quality parts.

Ultimately, a proactive approach to CNC machine maintenance and repair is the foundation of reliable high precision manufacturing.

Best Practices in CNC Precision Machining

To get great results in CNC machining, you need to follow best practices all the way through the process. One of the most important is using high quality cutting tools and selecting the right material, as these directly impact accuracy, surface finish and durability of the parts. Regular inspection and timely replacement of cutting tools helps to keep them sharp and precise and reduces defects.

CNC programming is another critical best practice. By fine tuning parameters like feed rates, spindle speeds and coolant application, manufacturers can improve machining efficiency and reduce errors. Advanced CNC programming also allows for complex geometries and ensures each part meets specifications and tolerances.

A robust quality control process is key to verifying parts meet design requirements. This includes inspection, measurement and testing at various stages of production. By following these best practices, manufacturers can improve consistency and quality of their CNC machining, reduce waste and rework and build stronger relationships with their customers through better products.

Applications of CNC Precision Machining

CNC precision machining has many applications across multiple industries and produces high quality and precise components. From automotive to medical devices and aerospace, CNC precision machining is key to modern manufacturing.

Automotive

In the automotive industry, CNC precision machining is used to develop quality prototypes and functional components. This allows manufacturers to create complex parts with high accuracy so vehicles perform and are safe.

Precision machining is used for automotive parts such as engine components, transmission parts, repair parts, electronic enclosures and identical parts — showing its versatility and importance.

Medical Devices

The medical industry relies heavily on CNC precision machining to create intricate and precise medical devices and implants. This ensures surgical instruments and other medical components meet exact specifications for safety and effectiveness.

By maintaining high standards of accuracy and quality, CNC precision machining helps develop life-saving medical devices and technologies.

Aerospace Components

CNC precision machining is critical in the aerospace industry, where safety and precision are paramount. Common aerospace components manufactured using this process include:

- Landing gear ports

- Bushings

- Manifolds

- Airfoils

The ability to produce complex parts with tight tolerances ensures that aerospace components meet the stringent safety standards required in the industry, preventing errors that could endanger lives.

Conclusion

CNC precision machining is the backbone of modern manufacturing — it's all about accuracy, efficiency and versatility. From the processes and technologies to the applications and benefits, CNC precision machining is a must-have across all industries.

As we wrap up this guide, we hope you have learned something new about CNC precision machining. Go ahead and embrace the precision, efficiency and innovation that comes with it and explore the endless possibilities it brings to manufacturing.

FAQ's about CNC Precision Machining

What is precision machining?

Precision machining is a CNC machining process that uses computer-controlled machine tools to produce parts with tight tolerances and complex geometries. This is the key to high accuracy in manufacturing.

What are the benefits of CNC precision machining?

CNC machining has many advantages like tight tolerances, high accuracy and repeatability — which adds up to low cost and high efficiency. Also, it's safer in manufacturing environments.

What materials are commonly used in precision machining?

Common materials used in precision machining are metals like aluminum, brass, copper and titanium and plastics like polycarbonate and ABS. These materials are chosen for their machinability and functional properties.

How does CAD and CAM contribute to precision machining?

CAD and CAM help in precision machining by providing detailed digital models for accurate design and generating precise instructions for CNC machines — which results in high efficiency and precision in the manufacturing process.

What industries use precision machining?

Precision machining is required in industries like automotive, medical, aerospace and defense where accuracy and high-quality parts are critical.