Introduction

CNC machining tolerance is the amount of deviation from the specified dimensions, critical for part fit and function. Adding tolerances in the design phase is key to manufacturability and quality control. This article covers types of tolerances, factors that influence them and their impact on cost and precision.

Summary

- CNC machining tolerances are critical for dimensional accuracy and part fit, with some applications requiring extreme precision which can be achieved with advanced CNC technology.

- There are different types of machining tolerances: limit, bilateral, unilateral and Geometric Dimensioning and Tolerancing (GD&T), each serving different design and manufacturing requirements.

- Finer tolerances can cost more and take longer to produce due to the need for special equipment and higher precision, so it's all about finding the balance between precision and budget.

Understanding CNC Machining Tolerances

CNC machining tolerances are the critical measurements that define the allowable deviations in the dimensions of the parts, including standard machining tolerances. These CNC tolerances are important to ensure parts fit and function correctly, especially in high precision applications. Tolerances for CNC machining refer to the specific dimensional allowances and precision standards used to ensure part accuracy and quality control throughout the CNC machining process.

Key points about machining tolerances are:

- They define the range a parameter can be off from its intended value.

- They ensure the final product meets the required specs.

- Average tolerance for CNC machines is around 0.02mm.

- Advancements in CNC technology have reduced these machining tolerance values to the minimum.

The inverse relationship between tolerance values and accuracy means smaller tolerance numbers mean tighter tolerances and higher precision. For example, tolerances measured in several decimal places mean higher accuracy; CNC machines can achieve precision around ±0.0025mm.But Defining tolerances for every dimension can increase cost, so we need to balance precision requirements with budget and tolerance level.

Tolerances depend on many factors that need to be considered. Determining tolerances means understanding the part's intended use and functionality to establish the acceptable tolerance range.

Types of CNC Machining Tolerances

CNC machining tolerances ensure the parts are dimensionally accurate. These can be in metric or imperial depending on the project requirements. There are several types of CNC machining tolerances, each for different purposes and applications. Proper application of these tolerances will enhance the functionality and manufacturing efficiency of CNC machined parts.

The most common types of machining tolerances are:

- Limit tolerances

- Bilateral tolerances

- Unilateral tolerances

- Geometric Dimensioning and Tolerancing (GD&T)

Non-standard tolerances for parts requiring precision outside normal ranges

Each has its own benefits and is suited for different design and manufacturing scenarios.

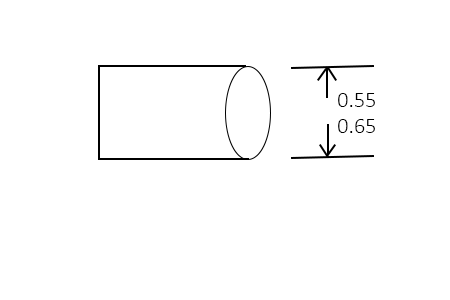

Limit Tolerances

Limit tolerances give you a clear range by defining the minimum and maximum size for parts to fit properly. These tolerances are calculated by adding or subtracting variation from a nominal size, which sets the upper and lower limits. For example, a limit tolerance of 0.55–0.65 mm means the final dimensions must be within this range. If a part is outside the specified limits, it's rejected.

After setting these upper and lower limits, the concept of Maximum Material Condition (MMC) becomes important. MMC is the largest or smallest size of a feature within the specified limits, which affects assembly fit and allows for bonus tolerances in GD&T.

This makes it easy to understand by giving you a straight forward acceptable range. Deviation in machining tolerances including upper deviation are measured as allowed variance of the maximum deviation allowed size from the basic size.

Limit tolerances ensures parts fit and function as intended and manages dimensional accuracy in CNC machining by applying tolerances to get tight tolerances.

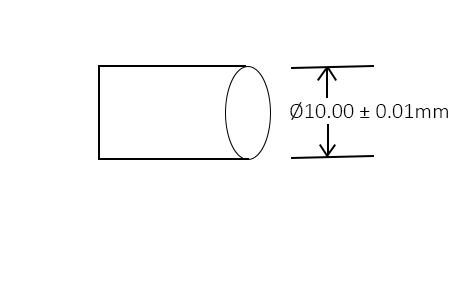

Bilateral Tolerances

Bilateral tolerances allow for deviation in both directions from a nominal value, where symmetrical variation is acceptable around the dimension. For example, a 0.01 mm bilateral tolerance on a 10 mm diameter pipe means the basic size is 10 mm, with limits of 9.99 mm and 10.01 mm.

These tolerances are applied to external dimensions and are expressed as equal variations, eg +/- 0.06 mm. Bilateral tolerances manage dimensional accuracy by allowing parts to vary within a controlled range while having different tolerances and functionality.

In addition to bilateral tolerances, profile tolerances are another type. Profile tolerances specify the allowed variation of a part's cross section within defined limits, controlling the shape and curvature of the profile line.

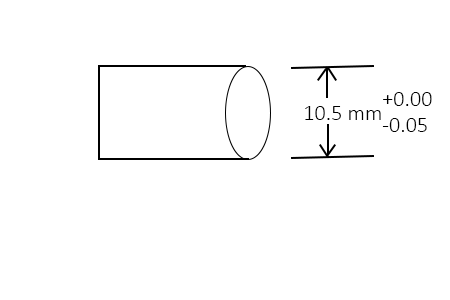

Unilateral Tolerances

Unilateral tolerances allow deviations in only one direction from a dimension, which is important for certain design applications where deviations can only be allowed on one side. For example a unilateral tolerance of 10.5 mm +.000/-.005 means a maximum dimension of 10.5 mm within certain dimensions and certain tolerance.

These tolerances are used in applications where exceeding the specified dimension would prevent a part from fitting into its intended position and would be rejected. For example a shaft with unilateral tolerances of 70 +0.00/-0.05 mm allows values from 70.00 mm down to 69.95 mm.

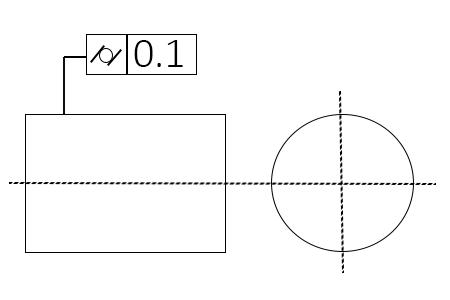

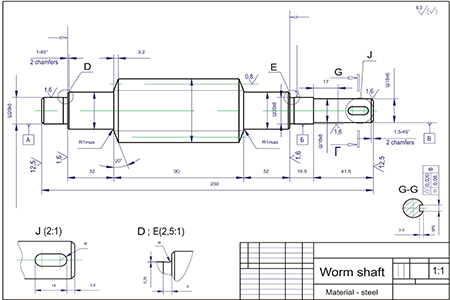

Geometric Dimensioning and Tolerancing (GD&T)

Geometric Dimensioning and Tolerancing (GD&T) is a standard way of detailing and communicating machining tolerances, including measurements and allowed variations. GD&T defines exact geometric characteristics such as flatness, concentricity, geometric tolerances and true position beyond just dimensional tolerances.

This system adds precision by defining geometric characteristics along with dimensional tolerances. GD&T is very important in CNC machining where parts often have high tolerance requirements. Using GD&T you can ensure that parts with very precise dimensions meet the standards.

Calculating and Expressing Tolerances

Calculating and expressing tolerances is a fundamental part of CNC machining to ensure every part meets its specifications. Machining tolerances are determined by setting upper and lower limits for each critical dimension. The tolerance is the difference between these two limits, the allowed range in which a part can be measured. For example if a part requires a diameter with an upper limit of 10.5 mm and a lower limit of 9.5 mm, the machining tolerance is ±0.5 mm. Any measurement between 9.5 mm and 10.5 mm is acceptable.

Clearly expressing these tolerances is key to good communication between designers, engineers and CNC machining services. It ensures everyone involved in the manufacturing process knows the allowed variance and the specific requirements for each part. By calculating and documenting the upper and lower limits you can control quality, reduce errors and ensure all CNC machined parts fit and function as intended. Mastering tolerance calculation and expression is the key to consistent results in CNC machining.

Factors Influencing CNC Machining Tolerances

Several things affect CNC machining tolerances:

- Material properties, hardness and abrasiveness, which can impact the tolerance during machining; surface roughness is also material dependent and can affect the finished part precision

- Manufacturing methods

- Part complexity

- Environmental conditions like temperature and humidity, which also affects machining precision and product quality

Different CNC machines have different capabilities, so tolerances are limited by the CNC machine used. Established CNC providers use the latest technology to improve production and accuracy.

Working with CNC experts can lead to design improvements and process optimization.

Material Properties

Material properties can affect your ability to hit certain tolerances. For example:

- Soft materials will bend during machining and make a mess.

- Plastics like Nylon, HDPE and PEEK won't hold tight tolerances like metals do due to heat from friction during cutting especially when cutting plastic parts. Material flexing will also affect the precision of the final product and the material condition. Heat stability will also affect the performance of these materials under stress.

- Abrasive materials will wear out cutting tools making it harder to hit the tolerance; so choosing the right cutting tool is key to handling different material properties and tolerances.

Knowing the individual properties of materials is key to hitting tolerances. Some materials are not compatible with processes to hit tight tolerances and will affect the final product's quality and functionality.

Manufacturing Methods

CNC milling, turning and grinding and additive manufacturing have different capabilities that affect the tolerances that can be achieved. Knowing the strengths and limitations of CNC machines is key to choosing the right method to get the tolerances you need.

Tolerances dictate the manufacturing process, finer tolerances limit the machine options in the process. In some cases additional operations are required. For example grinding and lapping can get you to the desired tolerances.

Part Design and Complexity

Complex part designs require special measurement tools and unique tolerancing to get precision. Complex designs present more challenges in holding tight tolerances, requires advanced techniques and equipment.

CNC Machine Capabilities

CNC machine capabilities are a big factor in determining the tolerances for any given job. Not all CNC machines are created equal—some are designed for standard CNC machining tolerances and others for very tight tolerances, sometimes as tight as ±0.001”. The ability to achieve those tight tolerances depends on several factors, the machine design, the quality of the components and the sophistication of the control systems.

When planning a machining job, you need to match the required tolerance to the CNC machine being used. For example complex parts or parts that require extremely tight tolerances need to be run on high precision CNC machines, while less demanding parts can be run on standard machines. Reputable CNC machining companies will provide detailed information on the standard CNC machining tolerances their machines can achieve so you can make an informed decision on which machine and process to use for your job.

Knowing the capabilities of different CNC machines allows you to optimize your machining process, achieve the level of precision you need and ensure tolerances in CNC machining are met.

Cost Implications of Tight Tolerances

Choosing tighter tolerances can add both time and cost to production due to wear on tools and specialized equipment. For example going from 0.030” to 0.005” can double the cost and going to 0.001” can quadruple the cost compared to 0.005”. This is due to the extra time and precision required in the machining process.

Also tighter tolerances can lead to higher scrap rates due to more parts being out of spec, which adds to the overall cost of sheet metal. The need for specialized inspection equipment to meet very tight tolerances, tighter tolerances, tight requirements and exacting standards adds to the cost in sheet metal.

Balancing precision with cost is key to optimizing production and budget.

Inspection and Quality Control

Quality testing and inspection is key to verifying CNC machined parts meet specifications. Here are some ways:

- First Article Inspection (FAI) to ensure the first part produced meets all design specs.

- Using a reputable CNC machining company to ensure consistent quality and tight tolerances.

- Non-destructive testing methods like ultrasonic testing to detect internal flaws without damaging parts.

- Providing material certifications to verify materials used and meet strict standards and specs.

Statistical Process Control (SPC) is used to monitor the process and quality by looking for trends and variances.Inspecting parts with tight tolerances takes more time and specialized tools to ensure quality. Tighter tolerances mean more complexity and may require specialized equipment during inspection, which adds to the logistics.

International Standards for CNC Machining Tolerances

International standards are key to CNC machining as they provide a common language and framework for specifying and interpreting tolerances. Standards like ISO 2768 and ASME Y14.5M give guidelines for geometric dimensioning and tolerancing so CNC machined parts meet global quality and dimensional accuracy requirements.

These standards cover all aspects of tolerancing, including how to specify tolerances for different features, how to apply geometric dimensioning and tolerancing (GD&T) and how to make parts interchangeable regardless of where or who made them. For mechanical engineers, designers and manufacturers, following these international standards is critical for getting reliable results, compatibility across global supply chains and meeting modern manufacturing standards.

By following international standards for CNC machining tolerances, your parts will not only meet the specs but also fit with other components and systems, supporting efficient and high quality manufacturing.

Choosing the Right Tolerance for Your Project

Tolerances are key to quality in manufacturing and can save you a lot of money. Choosing the right tolerance limit ensures parts work flawlessly and avoids unnecessary costs. The intended use of a part determines the accuracy required during machining. Industries like aerospace, automotive and medical devices require super tight tolerances for safety and functionality. Not specifying tolerances can affect the fit of assemblies and cause production issues.

Using Design for Manufacturing (DFM) can reduce costs associated with tight tolerances by optimizing the design criteria in the design phase. Using Geometric Dimensioning and Tolerancing (GD&T) allows for more tolerance zones, which can reduce costs.

Standard tolerances are more cost effective for parts that don't require high accuracy. An experienced CNC machining company can offer custom solutions to your project requirements and meet your tolerance needs.

Working with a Reputable CNC Machining Company

CNC machining services will get you the tolerances you need and overall quality. Outsourcing CNC machining projects will reduce technical headaches and give you access to expert advice and advanced machinery.

Clarwe, for example, is a leading Contract Manufacturing service provider specializing in Rapid Prototyping and Low/High Volume Production of Precision Components.

Conclusion

Understanding and applying CNC machining tolerances is key to getting quality and functionality of the parts. By choosing the right tolerances, balancing precision with cost and using advanced systems like GD&T, manufacturers can optimise their process and get high precision. Working with a good CNC machining company will get you even more quality and efficiency and make it easier to meet the modern manufacturing standards.

FAQ's about CNC Machining Tolerances

How precise is CNC machining?

CNC machining can be very precise; some machines can be as precise as ±0.0025mm. This allows for very small and detailed parts.

What do tolerances in CNC machining mean?

Tolerances in CNC machining means the allowed deviation from the final dimensions of a part, tighter tolerances means higher accuracy.

What is the standard tolerance for CNC machined parts?

Standard tolerance for CNC machined parts is ±0.1mm unless otherwise specified by the customer. Please confirm with us for your project.

How do specific tolerances affect the assembly of parts?

Specific tolerances affect the ease and accuracy of part assembly, small deviations can cause problems in fitting parts together. So it's very important to stick to the tolerances for optimal assembly and function.

Why do tighter tolerances cost more in CNC machining?

Tighter tolerances in CNC machining cost more because you need more precise equipment which requires more adjustments and more wear and tear. This means longer production time and more material waste.