Introduction

Understanding the CNC Turning Process

What Is CNC Turning?

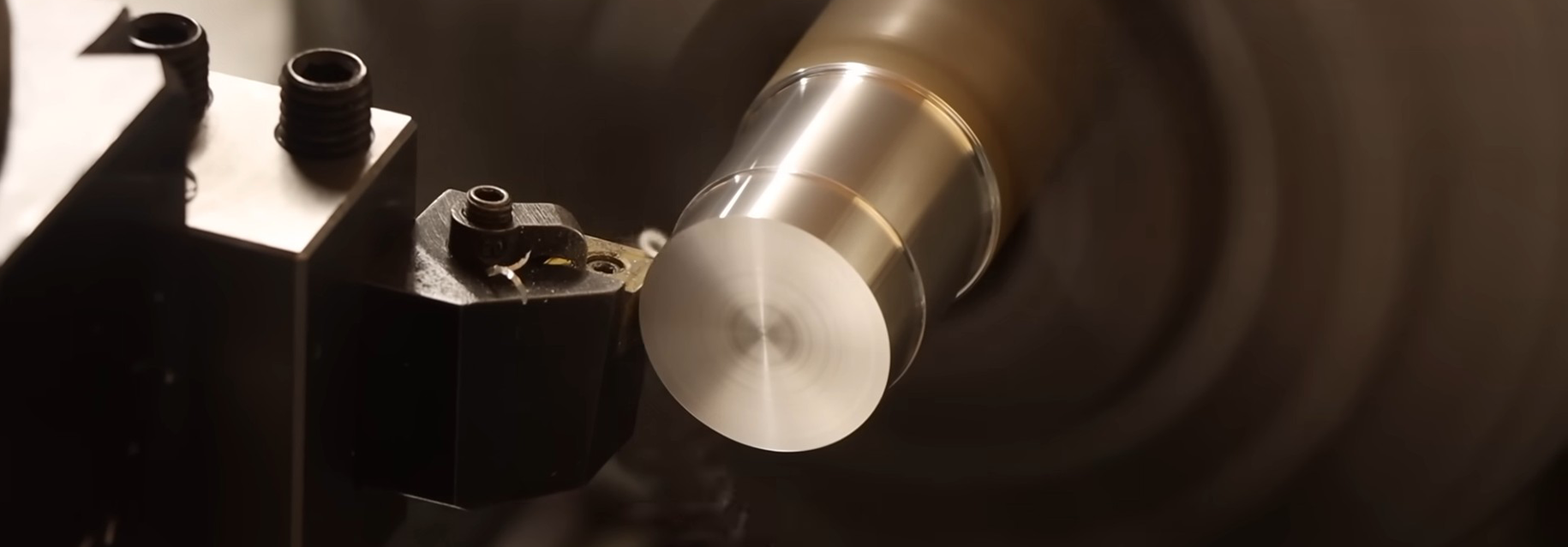

CNC turning uses computer numerical control (CNC) to guide a lathe or turning center. The workpiece is secured in a chuck and spins at set speeds. A stationary cutting tool moves against the material as it rotates. Subtractive machining takes place: each pass removes material to reveal the final shape. Every cut is pre-programmed, allowing for exact dimensions and repeatable results.Key elements of CNC turning:

The workpiece rotates, not the cutting tool.Material is removed layer by layer.

This setup offers strong control over diameters and surface finishes, making CNC turning a popular choice for anything from custom shafts to aerospace bushings. The machine automates movements for consistency.

How CNC Turning Works?

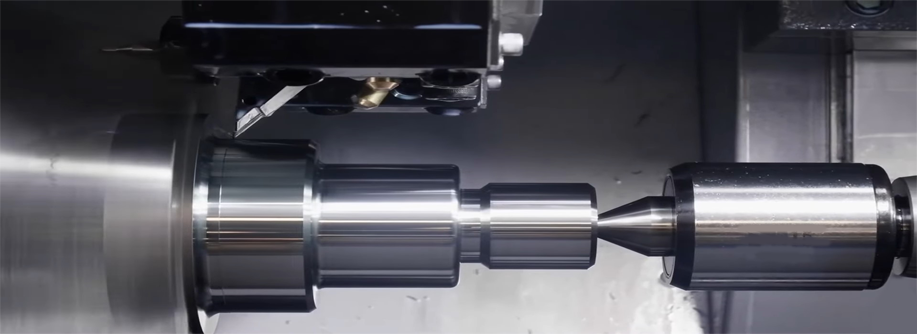

CNC turning starts with a detailed CAD file. This digital file maps the specifications for the part, including every diameter, groove and hole. The file becomes a set of instructions for the CNC lathe. A CNC turning machine uses a simple principle: rotate the workpiece and keep the tool steady. The operator loads the workpiece into the machine. Once activated, the lathe spins the workpiece at programmed speeds.The cutting tool then travels along two axes (usually X and Z). It cuts away unwanted material while the CNC system checks dimensions and step-by-step progress. Operators can also switch between tools for multiple machining needs—such as facing, drilling or threading—without removing the workpiece from the machine. This boosts productivity and reduces setup time.

Common Applications of CNC Turning

CNC turning is used in many sectors that need repeatable and reliable results. Common applications include:Automotive:

Pistons, pins, bushings and brake components.Aerospace:

Fasteners, spacers and landing gear parts.Electronics:

Housings and connectors for circuit boards.Medical Devices:

Surgical tools, implants and custom fittings.Parts have precise outer and inner diameters, smooth finishes and high repeatability—qualities often required by manufacturers with demanding specifications.

Materials Used in CNC Turning

CNC turning can handle a wide variety of materials. Choice of material depends on part function, strength requirements and desired finish. Some of the most common materials include:

Metals:

Aluminum, steel, brass, copper, stainless steel, titanium.

Plastics:

Nylon, PEEK, polycarbonate, acetal (POM).

Specialty Materials:

Ceramics, certain woods and composites when machinability allows. Each material comes with its own machining profile and characteristics. For instance, aluminum offers fast machining and lightweight performance, while stainless steel provides strength and corrosion resistance.Clarwe offer guidance for selecting both materials and machining methods, matching process strengths to customer priorities. This support ensures you get durable results and cost-effective production at scale with Clarwe'sCNC Turning Services .

Core Operations and Key Components in CNC Turning

Main CNC Turning Operations

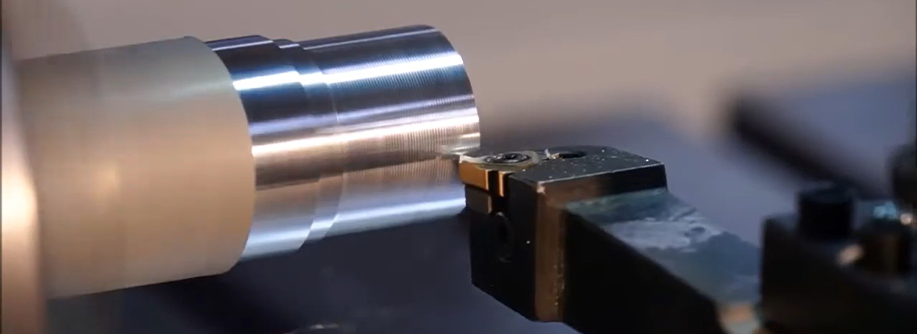

CNC turning uses a set of principal machining actions. Each one shapes the workpiece differently, letting operators produce a broad range of features on a single setup. Turning machines equip manufacturers with an array of standard and specialized operations that shape, finish and customize round and symmetrical components with high accuracy.External Turning and Facing

External turning processes remove material from the outside of a workpiece, shaping its diameter, length and surface features. Typical external operations include:

Turning:

This reduces a part's outer diameter, creating smooth or stepped shafts. For instance, drive shafts and axles in the automotive sector require turning for perfect roundness and balance.

Facing:

Facing tools smooth and square off the end of a workpiece. This is crucial when preparing components like flanges and bearing housings found in aerospace and automotive assemblies.

Taper Turning:

Parts that must connect with conical fittings, such as jet engine spindles, use taper turning to machine angled surfaces along their length.

Grooving:

A form tool cuts grooves or recesses, which serve as snap-ring seats or lubrication channels.

Parting (or Cut-off):

Parting cuts the finished piece from the bar stock. It ensures a clean separation—essential for high-volume production.Internal Operations: Drilling, Boring and Threading

Where external operations shape the outside, internal operations create features within a workpiece. Drilling, boring and threading adapt products for assembly, flow or fastening.

Drilling:

CNC turning machines use drills to make precise holes. Applications include mounting ports or lubrication passages in engine and hydraulic components.

Boring:

A boring bar enlarges or fine-tunes existing holes, achieving tight tolerances. High-precision bearings in aerospace and automotive rely on boring to ensure a proper fit and function.

Threading:

Threading tools carve helical grooves inside bores or on the outside of shafts. Internal threads let users screw parts together, such as attaching fittings to fuel rail housings.These internal operations offer reliable ways to customize each part for its job, from medical devices to robotics.

Other Specialized Turning Techniques

CNC turning machines support many specialized techniques for added performance or custom features:

knurling:

Creates patterned textures on surfaces for better grip, often used in control knobs or instrument handles.

Reaming:

A reamer polishes and brings holes to exact diameters with improved surface quality. This step is common in optical and measurement devices.

Hard Turning:

Machines hardened steels directly, saving steps in toolmaking and reducing time compared to grinding. It's ideal for high-wear tooling or bearing parts where hardness is critical.Each of these processes has a place in modern part design, enabling manufacturers to combine standard operations with tailored finishing.

For clients needing visible tool marks as proof of process or for functional prototypes, check theas-machined medium finish option to learn more about surface quality and finish choices.

Simple vs. Advanced CNC Turning Operations

Not all turning projects are equal. Simple jobs often rely on basic turning and facing, producing standard round parts with standard tolerances. These fit applications like custom bushings, washers or small batch fasteners with straightforward features.

Multi-axis Machining:

Allows for angled cuts and contouring, producing parts with more complex geometries.

Live Tooling:

Adds milling, slotting and small feature machining while the part is still spinning. This improves productivity and part complexity without a second setup.

Bar Feeding and Automation:

Automated bar feeders support high-volume, hands-off production—vital for industries needing consistent, large runs.The right operation mix keeps cycle times short and tolerances tight, regardless of volume. For tough applications—like parts requiring both high strength and resistance to wear—suppliers often select metals like titanium. Learn how Clarwe supports these projects by exploring their lineup ofTitanium Products

Core Components of a CNC Turning Machine

A CNC turning center is more than a spindle and a tool holder. Each component plays a focused role in delivering accuracy and reliability. Understanding the main parts can help when discussing requirements with machining partners or troubleshooting issues during production.Key components include:

Spindle:

Holds and rotates the workpiece at a controlled speed. The spindle's power determines the material types and cutting rates possible.

Chuck:

Grips the raw stock tightly. Collet chucks add grip for small, delicate parts, while three-jaw chucks suit most general work.

Bed:

The heavy base maintains alignment and absorbs vibration for stable, repeatable performance.

Tool Turrent:

Holds multiple cutting tools, switching rapidly during CNC cycles for efficient multi-step operations.

Tailstock:

Offers extra support for long or flexible workpieces, preventing deflection during turning.

Control Panel:

The user interface for programming, starting and monitoring all operations. These parts work in sync with advanced software to produce each part exactly as programmed. Selecting the right combination of materials and machine components is often guided by the requirements of the part. For instance, parts made from strong but machinable alloys likeAlloy Steel Products or high-performance plastics such asDelrin Plastic Sheets are common, depending on application needs.By mastering both the techniques and knowing what each component brings to the table, manufacturers achieve fast, accurate and reliable production through CNC turning.

Advantages and Limitations of CNC Turning

Advantages of CNC Turning

CNC turning stands out for making cylindrical components with tight tolerances using computer-driven processes. Here's why many manufacturers choose this technique:

Speed and Efficiency:

CNC lathes cut parts faster than manual machines. Operators load a CAD design, then the machine handles cutting with minimal supervision. For repeat jobs or high-volume runs, this can reduce lead times significantly.

Precision and Repeatability:

Advanced sensors and software help CNC turning hold tolerances as small as a few microns. This high accuracy is maintained from one batch to the next, even during long runs.

Versatility:

CNC turning supports a variety of materials—metals, plastics and composites. Operators can change tools or adjust programs to handle simple rods, complex components or large discs.

Cost Effectiveness for Certain Parts:

For components made in medium or large volumes, the efficient setup and fast run times can cut costs per part. Once programmed, the machines work longer hours with few errors.

Design Flexibility (within limits):

Operators can modify part geometry or size digitally, adapting quickly to new needs without large tooling costs.

Reduced Manual Error:

Fewer human touches lead to fewer mistakes. G-code drives each operation, decreasing the time spent on rework and scrap, as well as reducing occupational hazards since operators spend less time near live cutting tools.

batch Production Advantages:

CNC turning is scalable, supporting rapid prototyping and large-batch manufacturing without changing machines. This means consistent outcomes from the first run to the thousandth.

Safety:

Operators spend less time in direct contact with spindles or moving parts. Shielded work zones and automated material handling boost shop safety.

Less Material Waste:

CNC technology optimizes tool paths and part placement to keep waste minimal.

Streamlined Workflow:

Integration with CAD/CAM software simplifies design updates and prototyping. Machinists can make fast changes, which supports innovation cycles and tight timelines.Limitations of CNC Turning

Even with its strengths, CNC turning does face real-world limits:

Geometry Constraints:

CNC turning produces parts based on symmetrical rotation around a single axis. Features like slots, square holes or irregular profiles often require additional milling or secondary processes.

Design Restrictions:

The process excels with round features—shafts, bushings, flanges. But parts with sharp corners, deep slots or off-axis features can't always be finished in one setup.

Material Waste:

Subtractive machining removes material from a larger blank, which can generate scrap, especially with expensive metals.

Upfront Programming and Setup:

Complex parts need careful programming and selection of cutting tools, which adds prep time for prototypes or small batches.

Size and Weigh Limits:

Standard CNC lathes handle parts within certain sizes. Extra-large or unusually shaped items may require special equipment or processes.

Tool Wear and Maintainence:

Continuous production leads to tool dulling and increased downtime for change-outs, impacting cost and delivery for tough jobs.Material choice also has a big impact. For parts requiring extreme durability, corrosion resistance or specialty finishes, see the selection ofStainless Steel Products suited for demanding CNC turning projects.

Conclusion

Clarwe empowers businesses with reliable CNC turning services , combining advanced equipment and deep process knowledge for efficient results. Their support helps match materials and finishes to your exact needs, so you get dependable parts every time.

If your next project requires precise parts, consider CNC turning to streamline production and improve quality. For a broader look at how machining integrates with other methods, explore Clarwe'sCNC machining process.