Introduction

Summary

- Laser cutting technology allows for precise and efficient material processing across all industries using focused laser beams for complex designs.

- Fiber lasers are best for tube cutting as they are more efficient, cleaner cuts and longer lifespan than CO2 lasers.

- Despite the benefits laser cutting has it's downsides such as setup time, thermal issues and need for secondary operations to improve cut quality.

Understanding Laser Cutting Technology

Laser cutting is a modern marvel, it vapourises materials and gives you clean precise edges. It's a subtractive manufacturing process where material is removed to form the shape. Here's how it works:

- A focused laser beam that can cut through metals to plastics due to its high energy density. To start cutting the laser must first pierce or create an initial hole in the material before it can start the full cut.

- Generating the beam from a laser resonator. The laser source is where the laser beam is produced and different types of laser sources–CO2, Nd:YAG and fiber lasers—are used depending on the application and material.

- Directing the beam through optics to the cutting head, so the laser processing is precise. In fiber laser systems a fiber optic cable carries and amplifies the laser beam, keeping its power and quality throughout the process.

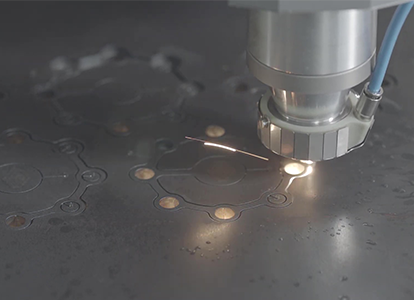

CNC is at the heart of laser cutting machines, for computer controlled precision. This means exact cuts and intricate designs that would be impossible to do by hand. There are two main methods of laser cutting, vaporization and fusion cutting. Vaporization is heating the material to its flash point to create a keyhole and then cutting. Fusion cutting is heating the material to its melting point and blowing away the molten material with a gas jet to get clean cuts with minimal material loss.

When talking about fiber lasers the laser beam is amplified in an optical fiber which allows for a very small spot size and high precision, they are perfect for cutting reflective metals and have advantages over CO2 lasers.

Laser cutting is versatile across many industries, from industrial manufacturing and architecture to small business. Its high precision makes it perfect for prototyping and low volume production runs where every mm counts. Whether you're dealing with metals, plastics or other materials laser cutting is a reliable and efficient solution.

Types of Laser Cutting Machines

Laser cutting machines come in many forms, each suited to different materials and applications. Here are the most common types:

- CO2 lasers: Used for non metal materials like plastics and wood. But lose power and quality over longer beam travel distance so not good for thicker materials.

- Fiber lasers

- YAG lasers (Nd:YAG lasers)

Fiber lasers have changed the game with their efficiency and low maintenance. They are good for cutting metals:

- Faster than CO2 lasers

- More precise than CO2 lasers

- Can cut through certain metal thicknesses quickly without significant power loss

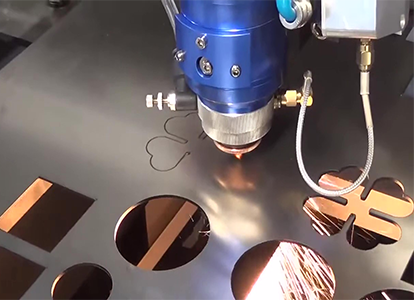

Fiber lasers are great for cutting reflective metals like copper which are a challenge for CO2 lasers due to reflection issues that can damage the equipment. That's why they are the go to for many industrial applications.

YAG lasers (Nd:YAG lasers) are used for precision work like engraving and micro-machining. They are great for applications that require detailed work on small parts. Hybrid laser cutting machines combine the features of both moving material and flying optics systems and are a versatile solution for all cutting needs.

Laser tube cutting machines are designed for tube and profile processing and can cut different tube materials and shapes. They often have automation and can use different lasers to meet industry requirements.

Each type of laser cutting machine has its own advantages so you need to choose the right one for your needs.

Advantages of Fiber Lasers in Tube Cutting

Fiber lasers are the preferred choice for tube cutting due to many advantages. One of the biggest is their longer lifespan compared to CO2 lasers which means lower maintenance costs and higher uptime. Low maintenance is a cost effective solution for long term use in industrial applications especially when using laser tube lasers.

Another big advantage of fiber lasers is they produce cleaner edges so less secondary finishing is required. This is especially important for industries where edge quality is critical such as high precision components manufacturing. The low heat affected zone in fiber laser cutting reduces material distortion so the integrity of the cut parts is maintained.

Fiber lasers have many advantages:

- Exceptional flexibility and precision

- Can adapt to different workpiece sizes and cutting patterns quickly so good for complex designs and intricate shapes

- Smaller beam size means faster cutting speeds

- Can cut complex shapes with high precision

These are the benefits of fiber lasers in modern manufacturing.

Material Capabilities in Laser Cutting

One of the best things about laser cutting is the ability to cut many different materials. Metals, plastics, wood, glass and even textiles can be cut with precision and speed. Laser cutting is particularly popular for sheet metal and stainless steel due to the precision and clean edges, perfect for applications that require tight tolerances and minimal post processing. This versatility makes laser cutting a must have in many industries. Woodworking uses laser cutting for precise engraving and intricate designs, jewelers cut detailed designs in precious metals with precision.

Laser cutting also excels at cutting materials with different properties. For example CO2 lasers can cut acrylic but you need to ventilate properly due to toxic fumes. Cardboard is an inexpensive option that can be cut clean with no toxicity. When it comes to sheet metal cutting, lasers have many advantages - better cut quality, faster and can cut various metal thicknesses. Ability to cut various materials including plastics makes lasers a go to for many manufacturing processes.

Material composition can affect laser performance. High thermal conductivity in materials like aluminum and copper can cause inefficient cutting and slower processing times. Laser cutting becomes less effective with thicker materials, often not effective for carbon steel beyond 0.4 inches. Knowing these material properties, capabilities and limitations is key to optimizing laser cutting, cutting thick materials, thin materials and material selection. When cutting thick materials, you need to consider the laser settings carefully to get the best results.

Precision and Accuracy in Laser Cutting

Laser cutting is all about precision and accuracy. Laser cutting machines can get down to ± 0.0005 inch, that's how accurate they are. The repeatability of laser cutters is 5 micrometers, so you get the same results every time you cut.

The diameter of the smallest part of the focused laser beam is less than 0.0125 inches (0.32 mm), that's how accurate the cutting is. Kerf widths, which is the gap the laser makes, can be as small as 0.004 inches (0.10 mm) depending on material thickness. That's how accurate laser cutting is.

The non contact nature of laser cutting also helps in precision by not damaging the material during cutting and maintaining material integrity. Calibrating the machine for specific material and adjusting cutting speed and power will give you the best results. All these factors combined gives you high quality laser cut parts, that's why laser cutting is the best for precision manufacturing.

Applications of Laser Cutting in Various Industries

Laser cutting is used in many industries, each taking advantage of its precision and flexibility. In the electronics industry it's used for component and printed circuit board fabrication, intricate designs and high quality products. In the automotive industry it's used for intricate parts and customisation, aesthetics and aerodynamics.

The aerospace industry uses laser cutting for lightweight high strength components that require precision. The defense industry uses laser cutting for critical vehicle and weapon components with high precision. In the art and design industry laser cutting is used for signage, event staging and custom furniture.

Emerging applications for laser cutting:

- Advanced composites, ceramics and glass, across many industries.

- Rapid prototyping in the packaging industry.

- Revolutionising manufacturing in construction, energy and agriculture with precision and speed.

Comparing Laser Cutting with Traditional Methods

Compared to sawing and CNC milling, laser cutting stands out for:

- Speed: Laser cutting can be up to 30 times faster than sawing, so much faster and quicker cutting times.

- Precision

- Cost-effectiveness

Traditional tube fabrication and inspection methods like physical contact sensors are slower and less accurate than laser based methods.

This speed advantage is especially useful for high volume production runs and tight deadlines.

In terms of precision, laser cutting can achieve tolerances down to 0.001 inch (0.025 mm) for very complex designs and detail work. This level of precision minimizes material waste, making laser cutting more cost effective than traditional methods. Plus laser cutting is generally cheaper than CNC milling especially for complex and custom parts.

The cost of laser cutting is dependent on material, part size, complexity and finishes. But overall the efficiency and precision of laser cutting makes it the preferred choice for many applications. Comparing these factors is why laser cutting beats traditional methods in performance and cost.

Challenges in Laser Cutting

While laser cutting has many benefits, it's not without its problems. Common issues with tube laser cutting are:

- Inconsistent tube shape and weld seams that affect cutting accuracy

- Geometric complexity of parts that slow cutting speeds

- Thermal issues during the process

- Difficulty in placing holes and through holes in tubes due to bowing

Quality checks like camera based systems are necessary to detect bow and twist in tubes during manufacturing. These advanced inspection methods ensure hole placement and overall product quality.

Setup for laser cutting can be a time consuming process, requiring precise adjustments to get the cutting parameters just right. Most laser tube cutting machines don't need a high powered laser, as too much power can damage the tube or cut through unwanted areas. Also a heat affected zone (HAZ) is formed during cutting which can cause brittleness and cracking in the material, especially near the cutting edge. This can be a big problem for materials with high thermal conductivity like aluminum.

Secondary operations may be needed to remove dross that can stick to the cut edges, especially on lower quality cut material. But understanding and addressing these issues can help optimise the laser cutting process and get good results. Being able to process different tube shapes and sizes is key for industries like agricultural machinery and light structural fabrication. By mitigating these issues you can get the most out of laser cutting.

Innovations in Laser Cutting Technology

Innovations in laser cutting technology, featuring advanced machines and techniques.

Future advancements will improve beam quality and get even more precise cuts and less waste. Laser cutting with automation and robotics has streamlined the process and machines can run 24/7 with minimal human intervention.

Modern laser cutting systems have advanced controls that allow real time adjustments during the cutting process and get more precise and less waste. Using high pressure nitrogen during laser cutting can also speed up and improve quality especially for reactive materials.

Some systems like laser microjets use total internal reflection within a water jet to guide the laser beam for precise cutting and debris removal.

These advancements are moving the industry forward and making laser cutting more efficient and versatile than ever.

Design and File Preparation for Laser Cutting

To get the best results with laser cutting you need to design and file prep carefully. When designing your design you need to consider the material thickness, cutting speed and the smallest feature size the laser can cut. These will affect the overall quality and precision of the cut.

Most laser cutting machines require specific file formats like DXF, DWG or SVG which are generated from CAD software or vector based design tools. Make sure your files are clean with clear lines and no overlapping paths so the laser can interpret your design correctly and avoid errors during the cutting process.

Also be aware of the capabilities and limitations of the laser system you're using, the maximum material thickness and cutting area. By designing for the material and machine you can get great results, minimize waste and have a smooth process from start to finish.

Best Practices for Successful Laser Cutting

To get the most out of laser cutting follow these best practices for high quality and precision. Start by choosing the right material for your application, taking into account thickness, density and how the material interacts with the laser. Fiber lasers are great for cutting metals with varying wall thickness, other lasers are better for plastics or thin materials.

Optimize your design for the laser cutting machine by considering the minimum feature size and making sure all details are within the machine's capabilities. During the cutting process adjust the focus, laser power and cutting speed to the material and finish. Regular maintenance of your laser cutting machine (cleaning optics and calibrating the system) will keep the quality and precision consistent.

By following these best practices you will get clean cuts and maximize your laser cutting efficiency. Whether you're using fiber lasers or other lasers, understanding the technology and the material is key to getting the best results.

Getting Started with Laser Cutting Services

If you're new to laser cutting services, choosing the right one is key. Consider the following when evaluating providers:

- Experience and customer reviews

- Different laser cutting technologies, they affect speed and accuracy

- What methods do they use

Research and ask questions before you decide so you can find the right one for your needs.

When requesting a quote for tube laser cutting, include project details, design files and specifications. Design files must be in the file formats specified by the service provider for processing. Also ask about turnaround times, they can vary greatly between providers.

Following these will make the laser cutting experience smooth and easy.

Conclusion

In a nutshell, laser cutting is precise and versatile, it's the backbone of modern manufacturing. We've covered the types of laser cutting machines and applications across industries. We hope we've given you enough information to consider laser cutting for your precision manufacturing needs.

FAQ's about Laser Cutting

What materials can be cut using laser cutting technology?

Laser cutting can cut metals, plastics, wood, glass and textiles. It's useful for many industries and projects.

What are the advantages of fiber lasers in tube cutting?

Fiber lasers are great for tube cutting because of their long life, low maintenance, clean edges and minimal thermal distortion. All of which means more precision and efficiency in the cutting process.

How does laser cutting compare to traditional methods like sawing and CNC milling?

Laser cutting beats sawing and CNC milling in speed, precision and cost. Tolerances up to 0.001 inch and minimal material waste. It's a winner for many manufacturing applications

What are some common challenges in laser cutting?

Common challenges in laser cutting are tube shape inconsistencies, part geometrical complexity, heat affected zones and secondary operations to remove dross. Addressing these is key to improving precision and efficiency in laser cutting.

What should I consider when choosing a laser cutting service provider?

When choosing a laser cutting service provider, look at their experience, customer testimonials and technology they use and their turnaround times. Also make sure your design files are in the required format for optimal processing.