Introduction

Tube is generally used for structural purposes and to describe hollow shapes like round, square, rectangular and oval shapes. The size of the tube is specified by outer diameter (OD) and wall thickness (WT). Pipes are classified as tubular vessels used to transport liquids, gases, or both hot and cold water in pipeline and piping systems. The size of a pipe is defined by its Nominal Pipe Size (NPS) and schedule numbers, which represent the wall thickness (WT). Tubes are more costly than pipes due to more precise manufacturing tolerances. Pipes are primarily used to transport fluids and gases inindustries such as oil and gas, plumbing, and construction. In this blog, we will specifically focus on tube bending - its terminology, methods and types.

What is Tube Bending

Bent tubes provide enhanced utility compared to straight tubes and are essential in various applications. They are widely used across industries such as construction, infrastructure,automotive, and manufacturing, where they serve purposes like structural support, components in machinery, or the transportation of fluids and gases.

Any type of metal tube can be bent including aluminium, stainless steel, mild steel, brass and titanium etc. These metals can be shaped into various forms and can be designed for specific uses. The most common bending shapes are U – bend, coil – bend, S – bend, L – bend. These shapes are made by applying force to the straight metal tubes.

Tube Bending Terminology

Center Line Radius (CLR)

Outer Diameter (OD)

Inner Diameter (ID)

Wall Thickness (WT)

Degree of Bend (DOB)

Center line Radius (CLR):

Also known as “Bend Radius”. The center line radius (CLR) is the distance from the center of curvature to the centerline of the tube. The radius can be the same as the radius of the die based on how it interacts with the tube.

Outer Diameter (OD):

Measured from one point on the outer edge of the tube to the opposite point passing through the center. This is the full width of the tube from the outer surface and is used to specify the overall size of the tube.

Inner Diameter (ID):

The inner diameter refers to the distance between the inner edges of the tube's cross-section passing through the center, and it helps to understand the amount of space inside the tube.

Wall Thickness (WT):

Measurement of difference between outer diameter and inner diameter. It defines the thickness of the tube’s material and Critical in selecting a bend die for tube bending.

Degree of Bend (DOB):

It refers to the angle created when a tube is bent, indicating the extent of the bend. Subtracting the degree of bend from 180° gives the bend angle.A smaller bend angle results in a sharper curve.

A larger bend angle creates a more gradual curve.

Understanding the Mechanics of Tube Bending

Outer – side thinning:

The reduction in the thickness of the outer side of a tube during bending is known as outer wall thinning. This occurs due to the deformation of the tube material as it bends. The outer side of the tube experiences tensile stress, which causes the material to stretch and become thinner.

Inner – side Wrinkling:

Inner side wrinkling occurs when the material on the inside of the bend is subjected to compression, leading to the formation of wrinkles. Excessive compression, a small bend radius, and the tube's wall thickness are the main causes of tube Wrinkling.

Wall Factor:

Wall factor refers to the relative wall thickness and is defined as the ratio of the outer diameter to the wall thickness of the tube.The wall factor indicates whether a tube is thick-walled or thin walled. Tubes with a lower wall factor are easier to bend, while those with a higher wall factor are more difficult to bend.

Springback:

Springback refers to the tendency of a tube to return to its original shape after bending. This results in an increase in the center line radius (CLR) as the tube tries to revert to its initial shape, causing the radius to expand. Springback is influenced by factors such as material stiffness, tensile strength, wall thickness, tooling, and the bending method used. Materials that are harder and have a smaller centerline radius (CLR) tend to produce greater springback.Types of Tube Bending

Form – bound bending:

The free-bound tube bending process involves tightly controlling and shaping the tube using a fixed die or tool. In this method, the tube is forced to follow the desired shape of the die or tool during the bending process, ensuring precise bends and preventing unwanted deformation.A die or form tool with a groove matching the desired bend radius and shape is used. The die is either rotated, or the tube is pulled around the die, causing the tube to conform to the shape of the groove. Since the tube is securely fixed to the die, its movement is tightly controlled, allowing bending only in the manner dictated by the die. This method is ideal for creating sharp bends and complex shapes, as the die fully governs the tube’s movement and form.

Advantages:

high precision, no deformation

Disadvantages:

complex setupFree – form bending:

Free-form bending is a method where a single die or tool is used to bend tubes with varying or continuous curves. Unlike traditional tube bending, which requires multiple tools such as a bend die, clamp die, and pressure die, free-form bending utilizes just one tool or die that fits the size of the tube.This method allows for the creation of any radius and is especially suitable for parts requiring bends greater than 180° or continuous multiple bends. In simpler terms, free-form bending relies on the tube's movement through the tooling to shape the bend.

Advantages:

single tooling, short lead time

Disadvantages:

less precision, inspection is difficult, expensiveHot Bending:

Heat-assisted tube bending is a method where the material is heated to make it more flexible and easier to bend. When the metal is heated, it becomes softer, allowing it to be shaped without breaking. This method is typically used formaterials that are difficult to bend or for bending tubes with larger diameters.The tube is heated to a high temperature, typically ranging from 400°C to 1150°C, depending on the material, making it soft and easier to shape using a bending machine. After bending, the tube is allowed to cool and harden again. It is crucial to ensure the temperature is high enough for flexibility but not so high that it causes the tube to melt.

Advantages:

can bend larger tubes, less force required

Disadvantages:

heat treatment, time consumingCold Bending:

Cold bending involves bending the tube without heating it, usually at room temperature. This method is used for materials that are thinner and softer, like aluminum.

Advantages:

cost – effective, used for soft metals

Disadvantages:

high force required, more chances of deformationPress Bending:

Also known as Ram bending, wherein the tube is fixed at two points, and a die is forced

against the tube to create the bend. The shape of the bend is determined by the external

dimensions of the die used.

Press bending is typically used for symmetrical parts, offering a fast process that doesn't

require lubrication or cleaning.

However, this method is not ideal for making bends with smaller angles or for precise control.

Therefore, it is generally used when a uniform cross-section is not a critical requirement.

Also known as Ram bending, wherein the tube is fixed at two points, and a die is forced

against the tube to create the bend. The shape of the bend is determined by the external

dimensions of the die used.

Press bending is typically used for symmetrical parts, offering a fast process that doesn't

require lubrication or cleaning.

However, this method is not ideal for making bends with smaller angles or for precise control.

Therefore, it is generally used when a uniform cross-section is not a critical requirement.

Advantages:

The cost of bending is cheap.Fast bending speed.

Disadvantages:

Cannot change the shape of the bend without changing the die themselves.It has less accuracy.

Always leads to deformation.

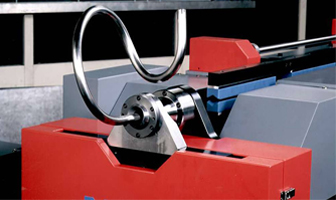

Rotary Draw Bending:

Also called “Degree bending” and “Angle bending”.

Rotary draw bending is a highly precise tube bending method that minimizes ovalization (the deformation of the tube's cross-section from round to oval after bending). This method uses a set of interlocking dies and an internal mandrel for support.

Clamp Die:

This die grips the outside of the tube and presses it against the bend die, keeping the tube steady during the bending process. As the bend die rotates to form the bend, the clamp die rotates and moves back.

Pressure Die:

Positioned tangent to the bend die, the pressure die serves two functions. First, it applies the necessary force to bend the tube and maintains constant pressure during the process. Second, it guides the straight part of the tube around the bend die.

Wiper Die:

Positioned just below the bend die, the wiper die prevents the tube from wrinkling on the inner wall of the bend. The wiper die material is usually made from the same material as the tube to prevent wear or damage during bending.

Mandrel:

The mandrel provides internal support to the tube during bending, preventing issues like wrinkling, ovalization, or breaking.

Advantages:

High accurate bends.

Disadvantages:

Forms bend at high speed.Roll Bending:

Also known as “Push Bending”.

This type of bending is used to create bends with a larger centerline radius (CLR). The method works by using three rollers arranged in a triangular pattern, with two fixed rollers and one movable roller. The fixed rollers rotate in the opposite direction of the movable roller. As the tube is passed back and forth between the rollers, it is gradually bent into the desired shape.

Advantages:

Can bend different tube sizes without changing tooling.Can create multiple bends in different planes.

Disadvantages:

The process is time consuming.Undergoes many trial and error methods before the start of process.

Damaging of tube is higher in case of small bend radius.

Compression Bending:

Nowadays, compression bending is less commonly used compared to rotary draw bending and roll bending. Compression bending is typically used for bending round hollow tubes, but it does not provide mandrel support. In this method, the tube is compressed by a pressure die along the form die, while the wiper die guides the tube around the form die. Due to the lack of mandrel support, a slight flat surface is formed at the end of the tube after bending.

Advantages:

Bending is fast.Simple tool setup.

Disadvantages:

Can be damaged easily.Only applicable for tubes of limited diameter.

Not applicable for small radius bend.

Conclusion

At Clarwe, we deliver high-precisiontube bending services for complex geometries and tight-tolerance applications. Whether you're developing lightweight aerospace assemblies, high-performance automotive chassis, or custom medical devices, our advanced equipment and skilled team ensure consistent accuracy and repeatability. We work with a wide range of metals and diameters, offering both standard and custom bends to meet your exact design requirements. With ISO-certified processes, quick lead times, and dependable delivery, Clarwe is your trusted partner for precision tube bending—no matter the scale or complexity of your project.

Need a fast and accurate quote?

Send us your specifications, and we’ll provide a tailored estimate to match your needs and timeline.