Introduction

When a commercial aircraft takes off with 300 passengers on board at 35,000 feet, everything has to work flawlessly. The landing gear components supporting tons of weight on touchdown, the jet engines producing thousands of pounds of thrust, and the aircraft systems maintaining pressurization – all rely on machined parts made to aerospace standards that accept nothing but perfection.

The aerospace industry is a global industry with huge economic value, encompassing segments like aircraft manufacturing, maintenance, repair and overhaul (MRO), and space technology. These segments feed into the global aerospace activity.

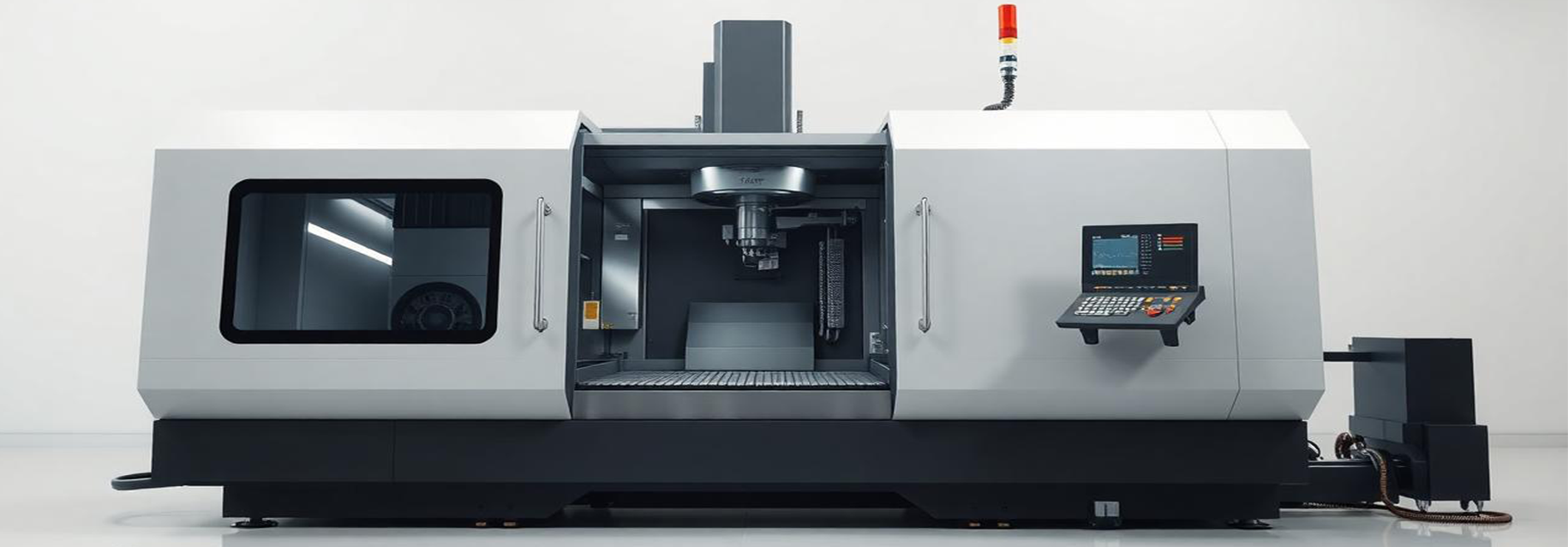

CNC machining for aerospace is the ultimate in precision manufacturing where computer-controlled processes create safety-critical components from the world’s toughest materials. This subtractive manufacturing technique uses automated cutting tools guided by CAD/CAM software to produce aerospace parts – airframe components, engine parts, and other structures – with tolerances in microns, not millimeters. CNC machining allows manufacturers to produce a wide variety of parts in one setup.

The aerospace industry demands zero-tolerance manufacturing because failure is not just expensive – it’s catastrophic. From military aircraft doing combat missions to spacecraft exploring the universe, aerospace machined parts have to withstand extreme temperatures, crushing pressures, and relentless vibration while maintaining structural integrity throughout their life.

This guide covers everything to do with CNC machining for the aerospace industry – from the advanced materials and processes to the strict quality control measures that ensure every component meets flight safety standards.

What is CNC Machining for Aerospace?

CNC machining for aerospace is a specialized process where digital instructions guide automated cutting tools to create parts critical to flight safety and reliability. This is a very precise process as computer-controlled accuracy eliminates human error and ensures repeatability of thousands of identical parts.

The foundation of CNC machining is in its integration with Computer-Aided Design and Manufacturing (CAD/CAM) software systems. Engineers design aerospace parts digitally using CAD programs, then CAM software translates those designs into G-code — the programming language that tells CNC machines how to move cutting tools through 3D space.

CNC machining excels at making parts with complex geometries and tight tolerances so even the most intricate designs are made accurately. This digital workflow ensures complex geometries conceived in engineering departments translate perfectly to physical parts on the factory floor.

Zero-Tolerance Manufacturing Requirements

Aerospace operates under a different safety paradigm than other industries. Where automotive parts might be good enough with tolerances of ±0.001”, aerospace parts need to be within ±0.0001” — ten times tighter than standard manufacturing tolerances. CNC machining is used in aerospace to achieve the required tolerances.

This level of precision is critical when machining valve components for hydraulic systems or electrical connectors that must seal perfectly in pressurized environments.

The process must account for materials that work harden under cutting forces, thermal expansion during machining, and the microscopic surface finishes required for optimal aerodynamic performance. Turbine blades, for example, require surface finishes of Ra 0.4 microns or better to minimize air turbulence and maximize fuel efficiency in jet engines.

Safety-Critical Component Manufacturing

Every aerospace part has a safety-critical function, whether it’s landing gear supporting the weight of the aircraft during landing or wing ribs maintaining structural integrity during turbulence. The cost of these components is not just the material cost but the testing, documentation, and certification required to prove airworthiness.

Quality control and certification are key to protect the customer and maintain their trust in aerospace products.

CNC machines making aerospace components run under Statistical Process Control, where every aspect of the machining operation is monitored. Temperature sensors track thermal expansion, vibration monitors detect tool wear before it affects surface finish, and in-process gauging systems verify dimensions while parts are still in the machine fixture.

Advantages of CNC Machining in Aerospace Manufacturing

The aerospace industry adopted CNC machining because of the fundamental advantages that align with the industry’s requirements for precision, consistency and reliability. These go far beyond automation, creating capabilities that were impossible with manual or semi-automated processes.

CNC machining has also led to increased sales and market competitiveness for aerospace companies.

Precision and Accuracy Requirements

Modern aerospace components are achieving tolerances that are pushing the boundaries of mechanical precision. While general aviation might accept tolerances of ±0.0005 inches, military aircraft and spacecraft require tolerances of ±0.0001 inches.

When machining high value metals used in aerospace components, these metals are critical for strength, durability and performance. This level of precision is critical when machining motion controls for flight surfaces where even microscopic variations in component dimensions can affect aircraft handling.

The precision advantage extends to surface finishes where aerospace parts often require Ra values below 0.4 microns. Turbine blades for jet engines need to achieve these mirror-like finishes to minimize boundary layer separation and maximize aerodynamic efficiency. CNC machines with high-frequency spindles and adaptive feed controls can achieve these surface finish requirements while removing material at production rates.

Geometric Dimensioning and Tolerancing (GD&T) compliance is another precision requirement. Aerospace parts have complex tolerance relationships where multiple surfaces must maintain specific angular and positional relationships. 5-axis CNC machines can machine these complex features in one setup, eliminating the cumulative errors that occur when parts transfer between multiple machines or fixtures.

Complex Geometry Manufacturing

The aerospace industry produces parts with geometries that defy conventional manufacturing. Turbine blades have twisted airfoil sections and internal cooling passages, structural parts have thin-walled sections to minimize weight and maximize strength. Using lightweight materials is critical to create these complex aerospace parts to meet weight and strength requirements.

These complex geometries require multiple machine axes to move simultaneously to maintain proper cutting tool angles and feed rates.

Five-axis simultaneous milling has changed the game for aerospace parts production by allowing continuous machining of complex surfaces without part repositioning in fixtures. A part that once required multiple setups and manual intervention can now be machined complete in one hit, improving accuracy and production time.

Machining internal features is another big advantage. Engine casings for modern jet engines have internal cooling channels and mounting bosses that were previously impossible to machine as a single part. Advanced toolpath strategies allow CNC machines to reach these internal features while maintaining the aggressive material removal rates needed for production.

Material Efficiency and Cost Reduction

Raw material costs are a big chunk of manufacturing costs in aerospace, especially when working with titanium alloys and nickel-based superalloys that can cost hundreds of dollars a pound. Optimized CNC machining can reduce material waste by up to 40% compared to traditional methods, which is a big cost savings on high-value material.

Adaptive machining adjusts cutting parameters in real time based on material conditions and tool wear, extends tool life and maintains surface finish. When machining titanium, these adaptive controls can extend tool life by 25–30% while maintaining the aggressive feed rates needed to prevent work hardening.

Near-net-shape machining is another efficiency advantage where CNC machines remove minimal material from precision forgings or castings. This reduces material waste and machining time while maintaining the metallurgical benefits of formed material. Landing gear components often use this method to combine the strength of forged material with the precision of CNC machining.

By improving material efficiency and reducing costs, aerospace manufacturers can increase their bottom line through higher margins and competitiveness.

Essential Materials for Aerospace CNC Machining

The selection of materials for aerospace applications is a balance of performance, weight and manufacturing. Each material category has its own unique machining characteristics that require special tooling, cutting parameters and quality control to get good results.

Leading aerospace companies like Lockheed Martin use advanced materials and CNC machining to make high-performance parts for their products.

Aluminum Aerospace Applications

Aluminum alloys are the dominant material for structural aerospace applications due to their high strength-to-weight ratio and excellent machinability. 7075-T6 is the backbone for wing ribs, fuselage frames and landing gear components with ultimate tensile strength over 83,000 PSI and less than one-third the density of steel.

Aluminum alloys have a machinability rating of 150–200, making them one of the most production-friendly materials in aerospace manufacturing. High-speed machining can achieve spindle speeds over 15,000 RPM when machining aluminum structures to remove material quickly and get good surface finish.

But aluminum machining has its own challenges that require process control. Chip evacuation becomes critical in deep pocket machining where aluminum tends to form long stringy chips that can interfere with tool performance. Flood coolant systems and high-pressure air assist help evacuate chips and prevent built-up edge on tools.

2024-T3 is used extensively in aircraft skin panels and pressurized structures with excellent fatigue and damage tolerance. These applications require thousands of precisely located holes, so CNC machines with automatic tool changers and programmable coolant systems are essential for production.

Machining of Titanium Alloy

Titanium alloys are perhaps the most difficult materials to machine in aerospace CNC machining, with exceptional strength and corrosion resistance and notoriously bad machining characteristics. The Ti-6Al-4V alloy used in jet engine components and high-temperature structures has multiple challenges that require special approaches.

The low thermal conductivity of titanium (only 15% of aluminum) creates hot zones at the cutting tool edges, causing rapid tool wear and potential workpiece damage. Cutting speeds for titanium are 150–300 surface feet per minute, much slower than aluminum, and feed rates must be aggressive to prevent work hardening.

Flood coolant systems are a must when machining titanium. Many operations require high-pressure coolant to the cutting zone. Some aerospace manufacturers use cryogenic cooling systems that use liquid nitrogen to keep the cutting temperature below the work hardening and tool damage threshold.

Tool life when machining titanium is only 20–50% of steel, so tool management and replacement strategies are key to productivity. Carbide cutting tools with coatings and geometries designed for titanium can extend tool life and meet the surface finish requirements for aerospace components.

The Ti-6Al-2Sn-4Zr-2Mo alloy used in higher-temp applications is even more challenging due to its higher strength and work hardening. These materials often require interrupted cutting and constant surface speed control to prevent tool failure.

Northrop Grumman is one of the major aerospace and defense companies that use titanium alloys in their advanced aircraft and systems, so machining these challenges is critical.

Manufacturing Challenges of Superalloy

Nickel-based superalloys like Inconel 718 and Waspaloy are the ultimate challenge in aerospace machining, combining extreme strength with work hardening characteristics that can destroy cutting tools in seconds if machining parameters aren’t controlled. These materials allow jet engine operation at over 1000°F but require specialized expertise and equipment to manufacture.

Inconel 718 work hardens rapidly under cutting forces, creating a hardened layer that can reach 50–60 HRC within thousandths of an inch from the machined surface. This hardened layer must be removed completely in subsequent machining operations or it will cause tool failure. Constant surface speed and aggressive feed rates help prevent work hardening while maintaining production rates.

Superalloys have a built-up edge formation tendency. Cutting tools with specific geometries and coatings are required to minimize material adhesion. Ceramic and cermet cutting tools often perform better than carbide in superalloy applications, but their brittle nature requires rigid machine tool setup and vibration-free cutting conditions.

Waspaloy and other high-temperature superalloys used in turbine applications present additional challenges due to their increased hardness and abrasiveness. These materials often require grinding to achieve final dimensions and surface finish. CNC machining provides near-net shape preparation for subsequent grinding operations.

Key CNC Machining Processes for Aerospace Components

Aerospace components require a range of CNC machining processes, each optimized for specific geometries, materials and quality requirements. Modern aerospace manufacturing facilities use multiple processes to cover the full range of components and production volumes.

Advanced Milling Operations

Five-axis simultaneous milling is the cornerstone of modern aerospace component manufacturing, allowing complex geometries that were previously impossible to machine. This technology allows tools to approach workpiece surfaces at the optimal angle and maintain consistent chip loads and surface speeds through complex toolpaths.

Turbine blade manufacturing is a great example of five-axis milling, where twisted airfoil sections require continuous tool orientation changes to maintain cutting geometry. Being able to machine leading and trailing edges in one setup eliminates the positioning errors that accumulate when parts move between fixtures, improving accuracy and productivity.

Adaptive clearing strategies have changed the game for roughing in aerospace manufacturing by adjusting feed rates and cutting depths on the fly based on material engagement. This allows for aggressive material removal while protecting the cutting tools from overload conditions, especially when machining expensive titanium and superalloy forgings.

Trochoidal milling is the solution for deep slot cutting and material removal in tight spaces. This technique uses continuous circular tool motion to maintain consistent chip loads and prevent heat buildup that can damage heat-sensitive aerospace materials. Wing rib production often uses trochoidal strategies to remove material from complex internal geometries while holding tight tolerances.

High-efficiency roughing with optimized chip loads allows for fast material removal from large forgings while maintaining tool life. These strategies are key when machining landing gear components from large titanium or steel forgings where material removal rates can be 100 cubic inches per minute or more while holding tolerance.

Precision Turning Applications

CNC turning in aerospace goes far beyond simple cylinders, with live tooling capabilities to produce complex features on rotational parts. Modern turning centers can mill, drill and even gear cut in one setup, reducing handling and improving accuracy for shaft and housing parts.

Live tooling allows for production of aerospace fasteners with complex head geometries and thread forms that require secondary operations. High-strength bolts used in structural applications often have specialized head configurations for torque application and safety wiring, machined complete on CNC turning centers.

Sub-spindle operations allow for complete machining of complex rotational parts without human intervention, necessary for producing the high volumes of fasteners and small parts required in aerospace assembly. These systems can transfer parts between main and sub-spindles with micron-level accuracy for critical dimensions.

Thread whirling capabilities produce aerospace fasteners with better thread forms than traditional threading. This process creates threads by synchronized rotation of workpiece and cutting tool, achieving the surface finish and dimensional accuracy required for aerospace.

Polygon turning allows non-round cross sections on rotational components, useful for aerospace applications that require hex or square features for tooling. Motion controls and servo systems control rotational and linear motion to create these complex profiles while maintaining the precision required for aerospace.

Multi-Tasking Manufacturing Centers

Turning and milling in one machine has revolutionized aerospace component manufacturing by allowing complete machining of complex parts without transfers between machines. These multi-tasking centers eliminate the positioning errors and setup variations that occur when parts move between dedicated turning and milling machines.

Complex aerospace hydraulic system valves show the benefits of multi-tasking where cylindrical bodies need boring and complex port geometries need multi-axis milling. Being able to do both in one setup ensures features are in alignment and reduces cycle times and handling costs.

Simultaneous operation of multiple spindles and tool stations allows for true parallel processing where roughing is done on one station and finishing on another. This maximizes machine utilization while maintaining the quality control required for aerospace.

Automatic workpiece handling systems on multi-tasking centers enable lights-out operation for high-volume aerospace components. These systems can run for hours without an operator, necessary to meet aerospace company delivery schedules while maintaining quality.

Critical Aerospace Component Applications

CNC machining is used in every system of modern aircraft and spacecraft, from the most visible parts to the hidden components that make flight possible. Each application category presents different manufacturing challenges and requirements that drive innovation in machining processes and capabilities.

Engine Component Manufacturing

Jet engine components are perhaps the most demanding application for CNC machining, combining complex geometry with exotic materials and extreme environments. Turbine blades machined from Inconel 718 must withstand 1800°F temperatures and centrifugal forces that are thousands of g’s.

Turbine blades require 5-axis machining centers that can hold ±0.0002” tolerances to create the complex cooling hole patterns to run at high temperatures. These cooling holes are often 0.020” or smaller in diameter and must be precisely angled to provide the best cooling flow while maintaining blade integrity.

Compressor discs have different challenges, requiring dynamic balancing and surface finishes to run at 20,000 RPM or higher. The machining process must hold ±0.0001” concentricity to create the complex contours for aerodynamic efficiency.

Fuel nozzles have complex internal passages to control fuel spray patterns for combustion efficiency. The machining of these components often requires specialized micro-machining and EDM to create features that can’t be reached with conventional cutting tools.

Engine casings must hold precise bore dimensions and have complex mounting interfaces and internal flow passages. These components often start as large forgings weighing hundreds of pounds, and CNC machining removes most of the material to create lightweight finished components that can withstand extreme operating conditions.

Structural Component Production

Aircraft parts require high strength and weight optimization, which drives innovative manufacturing. Wing spars machined from 7075-T6 aluminum billets need to remove up to 90% of material while maintaining structure and hitting weight targets in ounces.

Fuselage frames require precise hole locations for riveting and assembly, often with thousands of holes that need to line up with adjacent structures. CNC machining centers with automatic drill cycles and tool changers can do this while maintaining ±0.003” tolerance over 20-foot-long frames.

Landing gear components need to withstand the forces of landing while maintaining precise dimensions for hydraulic and mechanical interfaces. These components start as large forgings or castings—CNC machining provides the precision surfaces for proper operation while maintaining the metallurgical properties for fatigue life.

Control surface actuators require precision bearing races and sealing surfaces to operate smoothly for millions of cycles. Machining these parts needs to be better than 16 microinches Ra and hit geometric tolerances so they fit and function with other parts.

Avionics and Electrical Components

The electronic systems that run modern aircraft require precision housings and enclosures that provide electromagnetic shielding while allowing service and maintenance access. CNC machining creates these enclosures with cutouts for connectors and displays while maintaining the structural integrity for aircraft environments.

Radar antenna housings need to be RF transparent while protecting sensitive electronics from the environment. Machining these components often involves advanced composite materials that require special tools and techniques to prevent delamination and maintain dimensional accuracy.

Heat sinks for avionics cooling systems need optimized fin geometries to maximize heat transfer while minimizing weight and space. CNC machining can create complex fin patterns that can’t be made with traditional manufacturing methods while maintaining the surface finish for heat transfer.

Waveguide components for aircraft communication and navigation systems require precise internal dimensions and surface finish to minimize signal loss and maintain system performance. Machining these components must hold tolerances of ±0.0005” while achieving surface finishes better than 32 microinches Ra.

Quality Standards and Aerospace Certifications

The aerospace industry operates under perhaps the most stringent quality requirements of any manufacturing sector, where component failure can result in catastrophic consequences. The certification and quality control systems that govern aerospace manufacturing reflect decades of experience and continuous improvement in pursuit of zero-defect production.

Industry Certification Requirements

AS9100 Rev D certification represents the gold standard for aerospace quality management systems, building upon ISO 9001 requirements with aerospace-specific additions that address configuration management, risk assessment, and product safety. This certification requires manufacturers to demonstrate comprehensive control over every aspect of their operations, from supplier qualification to final product delivery.

NADCAP (National Aerospace and Defense Contractors Accreditation Program) accreditation governs special processes that cannot be fully verified through inspection of finished products. Heat treatment, chemical processing, and non-destructive testing operations must demonstrate consistent results through extensive process documentation and periodic audits by industry experts.

FAA PMA (Parts Manufacturer Approval) allows manufacturers to produce replacement parts for aircraft under FAA jurisdiction. This requires technical documentation to prove replacement parts meet or exceed original equipment specs and remain airworthy for life.

ITAR (International Traffic in Arms Regulations) governs the manufacture and export of defense related aerospace parts, and requires manufacturers to implement security measures and personnel screening to protect sensitive technology information. This often impacts facility design and personnel policies for companies in the defense industry.

Inspection and Testing Requirements

Coordinate Measuring Machine (CMM) inspection is now required to verify the complex geometries and tight tolerances of aerospace parts. These computer-controlled measuring systems can verify hundreds of dimensions and generate the documentation required for aerospace quality systems.

First Article Inspection (FAI) procedures per AS9102 require verification of the first production units to ensure the manufacturing process is producing parts to print. This documentation becomes part of the permanent record and must be kept throughout the life of the part.

Non-destructive testing methods like penetrant, magnetic particle, and ultrasonic testing verify the structural integrity of aerospace parts without compromising functionality. These methods can detect internal flaws and surface defects that can’t be seen with visual inspection.

Material certification and traceability requirements ensure every part can be traced back to the raw material source, with documentation on chemical composition, heat treatment history, and mechanical properties. This traceability is critical for troubleshooting and design improvements based on field experience.

Surface roughness measurement capabilities to Ra 0.1 micron enable verification of the high surface finish required for aerospace. These measurements require special equipment and environmental controls to meet aerospace quality requirements.

Surface Treatments for Aerospace CNC Parts

Aerospace components face demanding operating environments that require surface treatments beyond what machining can provide. Polishing is a common post processing surface treatment to improve surface finish and durability of aerospace parts. These treatments must be integrated with machining processes to get the best results while maintaining dimensional accuracy.

Corrosion Protection Systems

Type III hard anodizing provides wear resistance for aluminum parts in abrasive environments, surface hardness above 60 HRC while maintaining dimensional stability. This is critical for landing gear and control surface bearings that need to withstand repeated loading cycles while maintaining precise dimensions.

Passivation treatments for stainless steel parts remove free iron contamination and enhance the natural corrosion resistance of stainless alloys. Aerospace applications require passivation testing to verify complete removal of surface contamination that can lead to corrosion in service environments.

Chromate conversion coatings provide corrosion protection for aluminum parts while maintaining electrical conductivity for electromagnetic compatibility. These treatments must be controlled to get uniform coverage while maintaining the dimensional tolerances achieved during machining.

Performance Enhancement Treatments

Shot peening treatments increase fatigue life in critical rotating and load bearing parts by introducing beneficial compressive stresses in surface layers. Intensity and coverage of shot peening must be controlled to get the desired stress while meeting surface finish requirements.

Thermal barrier coatings allow engine parts to run at temperatures that would destroy uncoated materials, using ceramic layers to insulate the underlying metal. Application of these coatings requires precise surface prep and dimensional control to fit with mating parts.

Physical vapor deposition (PVD) coatings provide wear resistance and reduced friction for cutting tools and component surfaces, extending life while maintaining dimensional accuracy. These coatings can be applied to microinches thickness while maintaining the surface finish from machining.

Ion implantation changes surface properties without adding thickness, creating wear resistant surface layers that maintain dimensions. This is especially valuable for bearing surfaces and contact areas that need to hold tight tolerances throughout their life.

Challenges and Limitations in Aerospace CNC Machining

Despite the capabilities of modern CNC machining, aerospace manufacturing has many challenges that impact cost, delivery, and technical capabilities. Knowing these limitations helps with planning and setting realistic expectations for aerospace projects.

These challenges can also impact the sales and commercialization of aerospace products by affecting sales numbers, market share, and ability to meet industry demand.

Economic and Technical Constraints

High cost of aerospace grade titanium and superalloys puts a lot of pressure on manufacturing; raw material cost can be 50% or more of the part cost for complex components. The cost of these materials requires optimized machining strategies to minimize waste while meeting quality requirements.

Longer machining times are a result of the conservative cutting parameters needed to meet quality and prevent tool failure when working with difficult-to-machine materials. Titanium parts can take 5-10 times longer to machine than aluminum parts, hugely impacting production capacity and delivery schedule.

Specialized tooling adds to the initial and ongoing cost for aerospace manufacturing. Tools for superalloy machining can cost 10-20 times more than standard carbide tools and have much shorter tool life; tool management is a big cost factor.

Lack of skilled operators to program and operate complex CNC machining systems creates a bottleneck in production capacity. Aerospace machining requires deep knowledge of materials, cutting strategies, and quality requirements that takes years to develop through training and experience.

Material-Specific Manufacturing Issues

Titanium work hardening is a never-ending problem for aerospace manufacturing; you have to constantly monitor cutting parameters and tool condition to prevent hardened surface layers that will destroy your next cutting tool. The window of cutting conditions is very narrow for titanium and very sensitive to machine condition and setup accuracy.

Inconel work hardens and builds up edge on cutting tools, requiring special cutting strategies and frequent tool changes to maintain surface quality. Built-up edge formation is unpredictable and can cause sudden tool failure and workpiece damage, so process monitoring is critical for superalloy machining.

Carbon fiber composite machining risks delamination and fiber pullout that can compromise structural integrity, requiring special cutting tools and machining strategies that balance productivity with quality requirements. Carbon fibers are abrasive and cause rapid tool wear and health and safety concerns that require special ventilation and handling procedures.

Aluminum chip evacuation problems in deep pocket machining can affect cutting tool performance and surface quality, especially in high volume removal. The long stringy chips of aluminum machining can wrap around cutting tools and workpieces, requiring robust chip evacuation systems and careful toolpath planning.

Aerospace CNC Machining Trends

The aerospace industry is moving fast, driven by fuel efficiency, environmental impact, and performance. These demands are driving innovation in CNC machining and manufacturing.

Industry 4.0

IoT sensors on CNC machines monitor cutting forces, temperatures, and vibrations that affect part quality and tool life. This data enables predictive maintenance to prevent machine failures and optimize cutting parameters for maximum efficiency.

Artificial intelligence algorithms analyze vast amounts of machining data to find patterns and optimize cutting strategies for productivity and quality. Machine learning can adapt cutting parameters in real time based on material and tool wear, potentially extending tool life by 25-30% while meeting surface quality requirements.

Digital twin technology allows virtual machining simulation and optimization before cutting actual parts, reducing development time and the risk of expensive mistakes when working with high-value aerospace materials. These virtual systems can simulate entire manufacturing processes to find issues and optimize toolpaths before production starts.

Advanced Materials and Processes

Additive subtractive hybrid manufacturing combines 3D printing with CNC machining to produce near net shape parts that minimize material waste and allow for complex internal geometries. This is particularly useful for titanium and superalloy parts where material cost is a big portion of part cost.

Ceramic matrix composites and metal matrix composites are entering aerospace applications and bring new challenges for machining and tooling. These advanced materials have high strength-to-weight ratios and high temperature capabilities but require specialized cutting strategies and quality control.

Advanced sensors for in-process quality monitoring enable real-time verification of dimensions and surface quality and potentially eliminate the need for post-machining inspection. These sensors can detect dimensional variation and surface defects during machining and allow for immediate correction before parts are complete.

Emerging Applications

Electric aircraft requires lightweight, efficient components that consume less energy while meeting safety requirements. The unique demands of electric propulsion are driving material and process innovation that will impact the broader aerospace industry.

Urban air mobility vehicle manufacturing for air taxis requires high volume production with aerospace standards, potentially driving automation and efficiency gains for the entire aerospace sector. These applications will require new cost management approaches while meeting safety requirements.

Space tourism and commercial space is creating new markets for aerospace components with unique requirements for reliability and performance in space environments. The growth of commercial space is driving demand for cost-effective manufacturing processes that meet space quality standards.

Supersonic aircraft requires advanced materials and manufacturing techniques that can withstand the extreme conditions of high-speed flight. The revival of supersonic passenger aviation is driving heat-resistant materials and precision manufacturing innovation that will benefit other aerospace applications.

Sustainable manufacturing is becoming more important; aerospace companies are looking to reduce energy consumption, minimize waste, and implement recycling programs for expensive materials. These sustainability initiatives are driving process and equipment innovation that improves environmental impact and operational efficiency.

Conclusion

CNC machining for aerospace is where technology, materials science and quality meet to enable modern aviation and space exploration. From microns to rare materials that can withstand extreme conditions, aerospace manufacturing pushes the boundaries of what’s possible in precision machining.

The industry’s focus on safety and reliability has driven innovation that benefits all industries, while the need for weight reduction and performance has driven material and process development that continues to evolve. As aerospace companies go for more efficient aircraft, sustainable manufacturing and more space exploration, CNC machining will continue to advance towards these goals.

The future of aerospace manufacturing is in the intelligent combination of advanced machining with real-time monitoring, predictive analytics and adaptive process control. These will increase productivity and quality while maintaining the zero tolerance approach to safety that’s the aerospace industry’s mantra.

For aerospace manufacturers, success is not just about investing in new equipment and skilled people, but continuous improvement and adapting to changing requirements. The companies that will thrive in this tough environment will be those that innovate while maintaining the discipline of quality that aerospace demands.